Level, Point Level & Pressure Measurement Sensors (Hazardous Area Zone 1 & Zone 2 ATEX IECEx) – VEGA

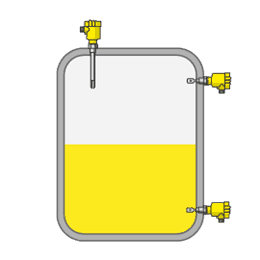

Continuous Level Measurement

USING VEGA sensors

Hazardous Area Zone 1 & Zone 1

ATEX IECEx CERTIFIED

Continuous Level Measurement

In continuous level measurement, the level of a medium in a tank or silo is detected with the help of different measuring methods and converted into an electronic signal. The level signal is either displayed directly on site or incorporated into a process control or management system.

Typical applications for continuous level measurement are process tanks, storage tanks or silos in the process and hazardous area industries.

- Liquids

- Pastes

- Powders

- Bulk Solids

POINT LEVEL MEASUREMENT

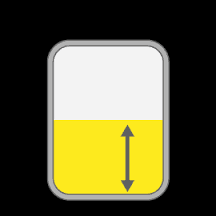

Point Level Measurement

In point level detection, a point level switch detects when a certain predefined level is reached. Such a device is employed when it is not necessary to measure every possible intermediate level, as is the case with continuous level measurement. A switching command starts or stops filling equipment such as conveyors or pumps. Point level switches outputting a binary signal can be integrated into a process control system.

Point level detection systems can be used in liquids, pastes, powders or coarse bulk solids.

Typical applications for point level detection in process tanks, storage tanks, silos and pipelines:

- minimum or maximum detection

- leak detection

- overfill protection

VEGA process instruments provide reliable and accurate point level measurement independent of installation position, pressure, temperature, foam, viscosity and grain size – with ATEX and IECEx certification suitable for both non-hazardous, Zone 1 & Zone 2 hazardous areas and potentially explosive atmospheres.

PRESSURE MEASUReMENT

Pressure measuring techniques can be used to measure not only process or differential pressure, but also level, volume, density or mass flow in all areas of process technology. The measuring ranges of pressure transmitters start at a few mbar and extend to extreme pressures up to 1,000 bar. Different measuring cells are used in these pressure instruments.

VEGA pressure transmitters deliver high-precision readings for safe and hazardous area locations:

- Gases

- Vapours

- Liquids

HAZARDOUS AREAS ZONE 1 & ZONE 2

Hazardous Area Zones

What is Hazardous Area Zone 1?

-

-

-

- Zone 1 Hazardous Area – a potentially explosive atmosphere in which an explosive liquid or gas atmosphere is likely to occur in normal operation. Although not officially quantified according to IECEx or ATEX but commonly accepted by hazardous area industries as being prevalent for more than 10, but less than 1000 h/yr.

-

-

What is Hazardous Area Zone 2?

-

-

-

-

- Zone 2 Hazardous Area – a potentially explosive atmosphere in which an explosive liquid or gas atmosphere is not likely to occur in normal operation and if it occurs will exist only for a short time. “Short time” is not officially quantified according to IECEx or ATEX but commonly accepted by hazardous area industries as being prevalent for less than 10h/yr.

-

-

-

Should you require any technical support to select and purchase the correct hazardous area level measurement sensor, please contact T&D.

➡ For complete technical specifications, ordering information and application details about VEGA Level, Point Level & Pressure Measurement Sensors please browse the product sections below.

Level, Point Level & Pressure Measurement Sensors

ATEX & IECEx Certified Sensors, Switches & Transmitters For Continuous Level, Point Level & Pressure Measurement In Hazardous Areas Zone 1 & Zone 2 and Explosive Atmospheres.

ATEX & IECEx Certified Level Measurement – specified throughout the global hazardous area oil, gas and petrochemical industries.

➡ For complete information and specification details about VEGA Level Sensors please see the product sections below.