Tank Heating By Eltherm

Published 16 Sep 2021

Tank Heating BY ELTHERM

Frost Protection For Industrial & Hazardous Areas Available From Stock At T&D

Electrical trace heating for tank containers provides a safe, sophisticated and reliable alternative to heating with glycol or steam. Whether for storage or transport, whether water tank, oil tank or tank container for chemicals, highly viscous or natural substances: an electrical trace or tank heating system ensures that substances of all kinds.

Sensitive chemicals such as MDI and petrochemical industrial substances to oil, grease, resin and paint to bitumen, adhesives and even foodstuffs can be stored, preserved or transported at the right temperature without heat loss.

If you want to claim the highest quality, you have to be able to guarantee that even complex liquids reach their destination undamaged and remain intact there. The best thing to do is to heat up the tank before it is filled.

Design and temperature regulation of a tank heater

Regardless of application, the tank heaters that a made from robust stainless steel with IP68 certification protect the tank’s contents against dust, foreign material, as well as dripping, spraying, jetting and salt water. Inside, a limited temperature controller ensures effective heat distribution and ideal heating levels. Redundant routing of the heating cables ensures safe and loss-free transport without cold zones even if one heating cable per heating circuit is damaged.

Technical Advantages

- Electrical controllers with a hysteresis of + / – 1 °C

- Repair of PTFE-insulated heat cables always and everywhere

- Monitoring and storage of temperature data at any time

- Tank container heating for hazardous areas with ATEX approval

- Low weight for minimal loss of vehicle payload and low additional fuel consumption

- Movable cables with very tight bending radius

- Operational capability of the entire fleet

- Exact temperature maintenance during loading and unloading

Control and design

differences depending on the type of tank

Temperature-sensitive chemicals are being used more and more frequently in the automotive industry, in mechanical engineering and in plant engineering. Therefore it is even more important to transport these chemicals safely.

This is predominantly done using tank containers, SWAP containers, road tanks and IBCs(intermediate bulk containers). Highly sensitive chemicals in particular are subject to stringent requirements for safe transport, which necessitate differences in design and control depending on the type of tank.

Electrical Heating for MDI Tank Containers

The transport of MDI (methylene diphenyl diisocyanate) requires a temperature of 43 °C, which may deviate by a maximum of + / – 1 K in the product. For worldwide transports, the voltage supply range must also be between 380 and 440 V, which makes additional protection against voltage peaks crucial with regards to the control system – especially when the supply is provided by the on-board network of a container ship or a ferry.

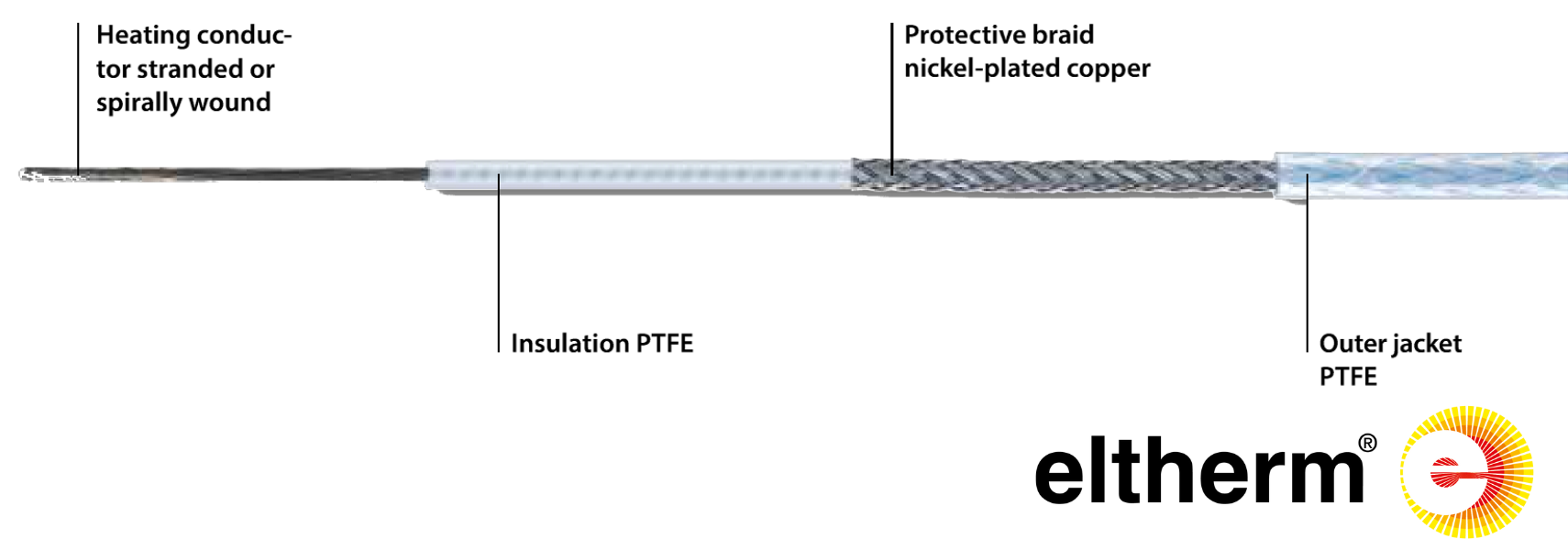

To meet all these requirements, eltherm offers a suitable of electrical heating solution in the form of a fluoropolymer-insulated ELKM-AG-L heating cable. In addition to the choice of heating cable, the method of laying the cable and its fastening is also important.

- Uniform heating of the entire container surface

- Recording of the product and heating cable temperature for each heating circuit

- Vibration-resistant components in stainless steel housing

- Separate heating options for dome boxes and riser pipes

Eltherm ELKM-AG-L Heater Cable – Resistance Heating Process Temperature Maintenance

Electrical heating of high temperature tank containers

For the transport of highly viscous materials from the chemical and petrochemical industry, suitable transport containers are required that can be used globally. Electrically heated 20′ Iso tank containers, SWAP containers and road tankers are ideally suited for this purpose. Special demands are made on the electrical heating system. High heating capacities with the lowest possible heat losses, brief heating of the empty tanks before filling, and resistance of the heating system to filling temperatures of up to 260 °C are all required.

Since these tank containers are generally operated without generators, an appropriate power reserve must be installed to be able to heat up the entire tank contents over several hours if necessary.

Technical Advantages

- Power ratings up to 18 kW

- Supply voltages between 380V & 440V

- Maintain temperatures up to 210 °C

- Specially manufactured tank container heating cables

- Uniform heating of the tank surface

- Multilayer insulation for efficient energy management

- Continued use of the heater without cold zones even in case of damage

- Operating hours counter for documentation of energy

Electrical heating of chocolate containers

After mixing the raw materials necessary for the production of chocolate, they are conched. After conching (heating up to 90 °C with constant stirring), the chocolate is still unsuitable for actual consumption. Due to the increasing globalisation of the leading confectionery manufacturers, it is becoming more and more necessary to transport basic products such as fats, oils and cocoa butter as well as finished products, such as chocolate mass, between the individual production sites for further processing without any loss of quality.

For large quantities of chocolate, transport in liquid form is most economical way to move the product. To ensure that the chocolate does not lose its flavour properties or harden en route, the containers must be heated. Worldwide standardised means of transport such as 20′ iso tank containers, SWAP containers, road tankers as well as IBCs are used.

Technical Advantages

- Uniform heating by a fluoropolymer-insulated heating cable

- Compensation of heat losses

- Uninterruptible power supply

- Complete documentation of temperatures

Installation of the tank heating

Besides engineering, design and calculation, installation is part of eltherm’s superior range of services. In order to mount the respective tank heaters on the tank surface, a large opening is required for insertion, depending on the heating conductor.

In order to ensure uniform heating of the entire stainless steel tank, up to two-thirds of the tank surface is covered with the heater and taped with self-adhesive aluminium tape or high-temperature aluminium foil. The standard length of the supply line is 16 m. Other lengths are available on request. The capacity and maintain temperature depend on the tank specification as well as on the medium being transported.

Thorne & Derrick specialise in providing specialist heating for industrial and hazardous areas including Eltherm’s heat tracing cables and heated hoses.