How to Get the Best Performance from Your Heated Hose System

Published 22 Oct 2025

In industries where fluid transfer is mission-critical — from chemical processing and food production to aerospace and pharmaceuticals — the reliability of your heated hose setup can make or break your operation. Whether you’re maintaining product viscosity, preventing freeze-ups, or ensuring consistent flow rates, performance matters.

At Eltherm & Thorne & Derrick, we know that even the most advanced heated hose won’t perform optimally without proper planning, installation, and ongoing care. Here’s how to get the best out of your heated hose system — every time.

1. Get the Specification Right from the Start

Choosing the right heated hose begins with understanding your application. Key factors include:

- Fluid characteristics: temperature sensitivity, viscosity, chemical compatibility, pressure rating.

- Operating environment: exposure to chemicals, mechanical wear, extreme temperatures, or UV.

- Temperature control requirements: constant, adjustable, or sensor-based regulation.

Selecting the correct materials, length, and configuration upfront reduces downtime, energy waste, and maintenance costs. Look for industrial trace heating hoses specifically designed for your fluid type and operating conditions.

2. How to Ensure Accurate Temperature Control in Heated Hoses

Temperature consistency is vital to prevent product degradation or flow issues:

- Integrate sensors such as PT100s or thermocouples for precise feedback

- Pair with PID controllers to maintain target temperatures

- Ensure overtemperature protection to safeguard sensitive fluids and personnel

Accurate control improves product quality and maximizes energy efficiency.

3. Proper Installation Tips for Heated Hoses

- Respect the minimum bend radius to prevent kinking

- Use strain relief fittings to reduce mechanical stress at connection points

- Route hoses away from foot traffic or crush-prone areas

- Apply thermal insulation or jacketing to conserve energy and protect personnel

4. Regular Maintenance to Prevent Heated Hose Failure

- Inspect visually for cracks, kinks, or exposed wires

- Test electrical resistance and insulation periodically

- Clean connectors to maintain reliable thermal and electrical connections

A regular maintenance schedule ensures consistent performance and prevents costly repairs.

5. Choosing a Specialist Supplier for High-Performance Heated Hoses

Your heated hose is only as effective as the support behind it. Eltherm & Thorne & Derrick provide:

- Custom-designed heated hose systems for any process or media

- Full technical support for design, installation, and troubleshooting

- Fast turnaround on spares and replacements to minimise downtime

Partnering with a specialist supplier ensures that your industrial trace heating hoses perform safely and reliably.

6. Optimise Energy Efficiency and Reduce Costs with Heated Hoses

- Precise temperature control prevents overheating and wasted energy

- Insulated hoses maintain heat, lowering running costs

- Proper flow reduces operational and material losses

7. Frequently Asked Questions About Heated Hoses

What is a heated hose?

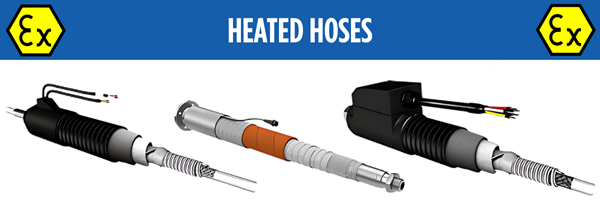

A heated hose is a flexible, insulated hose with integrated heating elements to maintain fluid temperature during transfer.

How do I prevent my hose from freezing?

Use properly rated industrial trace heating hoses, maintain accurate temperature control, and insulate the hose.

Can heated hoses handle chemical fluids?

Yes, if specified correctly. Ensure material compatibility with your fluid to prevent degradation.

How long do heated hoses last?

With proper specification, installation, and maintenance, heated hoses can last many years. Lifespan depends on usage, environment, and care.

Performance is Engineered, Not Assumed

A heated hose needs more than just heat — it needs thoughtful integration, expert support, and ongoing care. From accurate specification to smart control and professional support, every detail counts.