Explosion Proof Lighting for Hazardous Areas | Walkway Lighting

Published 27 Jun 2019

Walkway Lighting | Explosion Proof Lighting for Hazardous Areas

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager

Explosion Proof Lighting

Ensure Optimal and Uniform Light Dispersion With Explosion Protection Concept

Thorne & Derrick International, based in the UK, can design and supply IECEx and ATEX compliant hazardous area lighting systems for the oil, gas and petrochemical industries – in this article we review the application and specification of explosion proof lighting for walkway applications using Appleton manufactured light fittings.

Appleton ATX FELED hazardous area lighting can be used in onshore and offshore lighting applications where the end user would have specified explosion proof lighting using linear fluorescent type light fittings.

ATEX certified walkway lighting is a common application in hazardous area industries: these heavily trafficked areas must be illuminated evenly, safely and sufficiently to ensure safe passage with regard to changes of direction, level, stairs or any obstructions.

sufficiently to ensure safe passage with regard to changes of direction, level, stairs or any obstructions.

Vertical illumination is an important lighting system consideration in process areas that require monitoring of instrumentation.

Walkway lighting must also be designed with adequate overhead clearance for safe passage of people and equipment. In the event of a power disruption, an emergency backup system provides for safe escape.

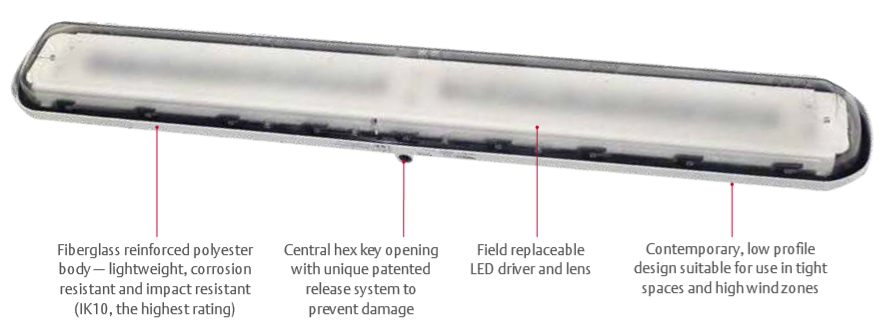

The FELED Series of hazardous area lighting manufactured by Appleton ATX provide end users and installers:

- A wide range of lumen outputs – exceeding the output of FE Series fluorescent lighting

- Pole and other mounting options to suit any walkway configuration and luminaire height

- A low profile design to maximize headroom even in confined spaces

- Rugged, corrosion resistant durability to withstand harsh offshore environments

- A 3-hour emergency version is available in the 5000 lm, 1.39 m (4.56 ft) luminaire

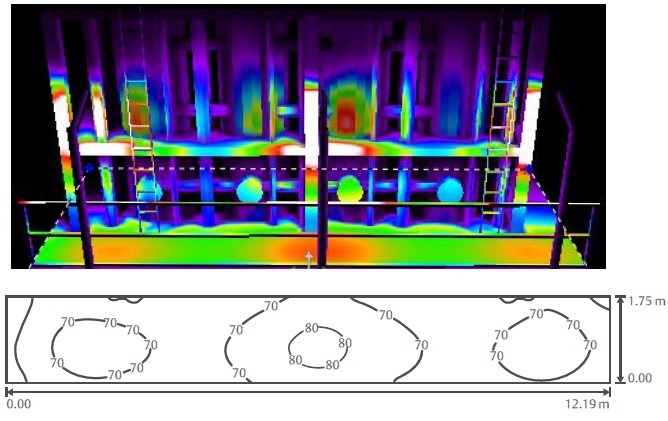

Walkway Lighting Application Simulation

FELED Series light fittings provide similar or higher lumen output and greater lighting uniformity compared to FE Series fluorescent fittings.

In walkway applications the hazardous area light fittings have potential to achieve illumination targets with fewer luminaires, higher mounting heights or reduced wattage light fttings.

In the application simulation below, three Appleton ATX FELED5 luminaires provide sufficient illumination for the walkway with good uniformity and vertical illumination.

Single Appleton ATX FELED Light Fitting

| Sample Application | Light Fitting Height | Type Of Mount | Light Fitting Spacing | Targeted Illumination |

| Walkway 1 m (3 ft) Wide | 3 m (10 ft) | 15° Pole Mount | 5 m (16 ft) | 50-75 Lux |

Single FELED Lighting

Explosion Proof Lighting Performance

| Luminaire | Size (Meters) | Size (Feet) | PowerConsumption (Watts) | Light Output (Lumens) | Eav (Lux) Floor | Emin (Lux) Floor | Emax (Lux) Floor | Emin / Emax |

| FEB236BUSA | 1.39 | 4.56 | 72 | 4423 | 70 | 51 | 82 | 0.62 |

| FELED5CBDSAD | 1.39 | 4.56 | 38 | 4650 | 74 | 52 | 86 | 0.65 |

Optical Radiation and Photobiological Safety Requirements in Lighting

Photobiology is the study of the interaction of optical radiation with living organisms. Optical radiation, another term for light, can be visible and invisible and is comprised of UV, IR and blue light emissions. It is strongly absorbed in tissue, with the skin and eyes of the human body most at risk of exposure. All visible light (380 nm to 780 nm) can, in principle, only damage the eye by thermal or photochemical effects.

The purpose of photobiological safety standards is to protect users from the harmful effects caused by optical radiations emitted by lighting devices. Within the European Union, the standards in the field of photobiological safety are IEC / EN 62471 and the more recent Technical Report IEC / TR 62778. The American standard in the field of photobiological safety is ANSI IESNA RP 27.

These standards define values for levels of risk ranging from Risk Group Exempt (RG0) (lamp / LED does not pose any photobiological hazard) to Group 3 (high risk) (lamp / LED may pose a hazard even for momentary or brief exposure).

Appleton FELED diffused luminaires are rated RG0, Risk Group Exempt.

Area Illumination: Safe, Efficient Explosion Proof Lighting

For proper illumination in extreme conditions, you need a lighting manufacturer who engineers their light fittings and luminaires to ensure optimal light dispersion, creating more usable light.

Upgrading from fluorescent to LED is seamless with a one-to-one installation retrofit.

Effective lighting is critical for worker safety and productivity; particularly when flammable gases, vapors and dusts are present in hazardous area locations. Midstream natural gas compressor stations are a prime example. Appleton FELED Series luminaires and light fittings provide:

- Certification for use in Zone 1 and Zone 21 hazardous locations

- Easy retrofitting to the FE fluorescent mounting hardware and footprint already in extensive use in these facilities

- A lumen output range suitable for everything from task, tunnel and walkway lighting to expansive spaces and higher mounting requirements

- A low profile that provides clearance in confined spaces and withstands high winds and jets of water in weather-exposed installations

- 60,000+ hours of operation with no lamps to change, minimising maintenance costs and maximising operational uptime

Explosion Proof Linear Lighting Fittings

Simple, Efficient, Low Maintenance Lighting for Hazardous Locations

Lighting ♦ Plugs & Sockets ♦ Control Stations ♦ Junction Boxes

Appleton ATX Hazardous Area Electrical Equipment

Full range of Appleton ATX Hazardous Area Products available from Thorne & Derrick stock and 5 Day Express Service:

-

- Plugs & Sockets | Zone 1 & Zone 2 Hazardous Area Plug & Sockets EX ATEX Certified

- Isolators & Safety Switches | Zone 2 Isolators & Safety Switches EX ATEX Certified

- Lighting | Zone 1 & Zone 2 Hazardous Area Lighting EX ATEX Certified

- Junction Boxes | Zone 1 & Zone 2 Hazardous Area Junction Boxes EX ATEX Certified

- Control Stations | Zone 1 & Zone 2 Hazardous Area Control Stations EX ATEX Certified

-

Invitation – network, engage, promote

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group – Process & Hazardous Area Industries : Heat Tracing, Gas Detection, Fluid Control & Flow Measurement. News, projects, videos, promotions, whitepapers, jobs, webinars, press plus much more.

ABOUT US

Thorne & Derrick International are your single-source supplier of Electrical, Mechanical, Process & Instrumentation Equipment. T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

T&D supply utilities, power, renewable energy, construction, rail, manufacturing, food/beverage, mining, oil, gas and petrochemical industries – distributing 100,000+ products from 100+ manufacturers from multi-million pound stocks. Since 1985 we have established a solid reputation based on service, integrity and trust.

Further Reading

-

Appleton ATX FELED Hazardous Area Lighting Zones 1 2 & Zone 21 22

Size: 648.76 KB

Appleton ATX FELED Hazardous Area Lighting Zones 1 2 & Zone 21 22

Size: 648.76 KB

-

Appleton ATX FELED – Data Sheet

Size: 538.83 KB

Appleton ATX FELED – Data Sheet

Size: 538.83 KB