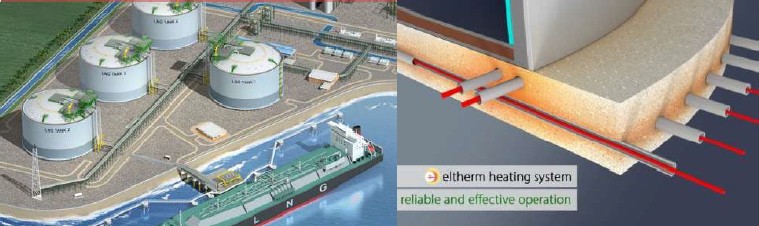

How Heat Trace Protects LNG Tank Foundations – SLNG Terminal, Indonesia

Published 18 Jun 2025

Project Spotlight – Heat Tracing for LNG Terminals

Project: SLNG Liquefied Natural Gas Terminal

Location: Papua, Indonesia

Scope of Supply:

- Engineering & Design

- Heat Tracing Materials

- Control Panels

- Cable Trays

- Installation & Supervision

- Testing & Commissioning

Project Highlights:

-

30 km of Trace Heaters installed for frost heave protection of LNG tank foundations

-

216 Heating Circuits engineered and commissioned

This large-scale application of electric heat tracing technology ensured the structural integrity and safety of cryogenic storage infrastructure in a tropical climate with LNG-induced subsoil freezing risks. The comprehensive solution delivered by the project team encompassed full lifecycle support—from design through to commissioning—ensuring long-term operational reliability.

Need A Trace Heating Solution?

With more than four decades of industry expertise, Thorne & Derrick are recognised leaders in delivering specialist trace heating solutions for a wide range of industrial applications. From hazardous zones and extreme climates to critical process control systems, we design bespoke solutions tailored to the specific needs of your operation.

Our services include comprehensive in-house heat loss analysis, system design, and technical specification, backed by a commitment to engineering excellence. Using only premium, market-leading heat trace cables and components, we provide cost-effective systems that enhance operational efficiency, minimise downtime, and support long-term project reliability—from initial concept through to full commissioning.