Flammable Solvents – Recommended IBC Selection According to Solvent Flash Point & Conductivity Group

Published 11 Dec 2020

Author: James Astley PH Europe (UN Approved IBC & ISOtank Services | Promoting Safe Handling for Hazardous Goods

‘Intermediate Bulk Container’ (IBC) | PH Europe operate a large stainless steel IBC rental fleet and sales operation in the UK.

IBC

Intermediate Bulk Container

An ‘Intermediate Bulk Container’ (IBC) is a container used for transport and storage of fluids and bulk materials. IBCs have become widely used in the solvents industry as they can transport and store a larger volume of material than cylindrically shaped containers in the same surface area. As the number of containers can be reduced with the use of IBCs, this, in turn, reduces manual handling, and they are also more resistant to weathering.

Many solvents in use by industry are identified under UN Class 3 as being flammable, highly flammable or extremely flammable. Solvents can also be split into three categories; conductive, semi-conductive or non-conductive.

Not all solvents can be used safely with every type of IBC and so it is important to take care when selecting the right IBC to use with a particular solvent. IBCs have also been involved in some recent incidents, such as stacks collapsing, the ignition of contents due to static electricity and leakage leading to serious fires and risk to the environment.

It is important to take care when selecting the right IBC to use with a particular solvent

The Solvents Industry Association has compiled an overview, Guidance Note 51, (https://www.solvents.org.uk/sia-guidance-notes/) regarding the selection and use of IBCs to increase awareness among solvent users and to promote best practice in the solvent supply chain. This guidance should not be used in isolation and reference should be made to other Standards and Codes of Practice. In devising its methodology for the safe selection of IBCs, the SIA has sourced the classification of solvents into conductive / semi-conductive / non-conductive from existing Codes of Practice, but as their recommendations concerning the selection of IBCs for low-flash solvents are not universally agreed, the SIA has based its recommendations on the experience of the Solvents Industry in the UK environment.

Some solvents and pure hydrocarbons have low conductivity and therefore, present a significantly greater static risk than others as there can be a build-up of static charge which can spark a fire or an explosion.

To eliminate this hazard, the operator can either use a metal IBC (examples at www.pheurope.com) or an electrostatic protected composite IBC with a suitable specification, in combination with a suitable earthing system when filling or emptying, subject to the product’s flashpoint.

The tables below indicate the recommended IBC types to be used with low conductivity and low flash-point solvents

| IBC Type (if compatible) | Flash Point of Solvent | ||

| <0ºC | 0ºC to 60ºC | >60ºC | |

| Unprotected Composite | No for N, S, C | No for N, S, C | Yes for N, S, C |

| Electrostatic Protected Composite | No for N, S Yes for C |

||

| Electrostatic Protected Composite With Conductive Plastic Bottle & Permeation Barrier | |||

| Steel | Yes for N, S, C | Yes for N, S, C | |

| Key: N = Non-conductive, S = Semi-conductive, C = Conductive solvents | |||

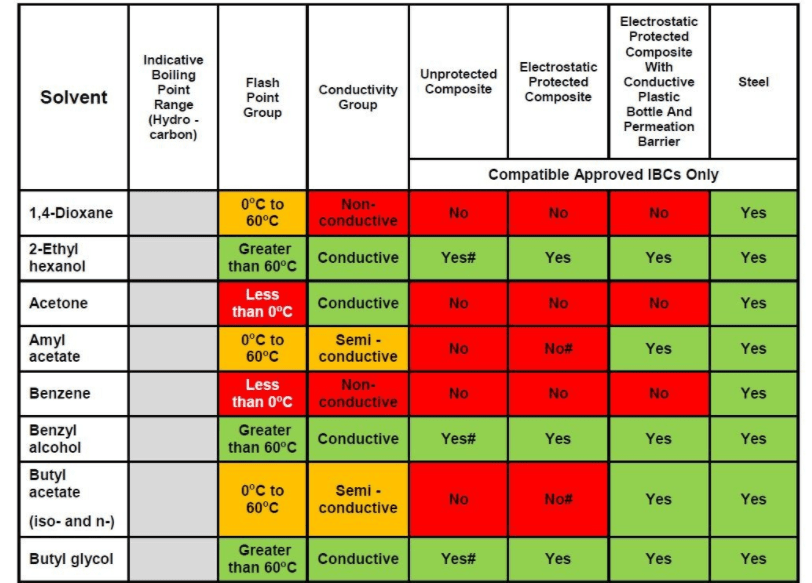

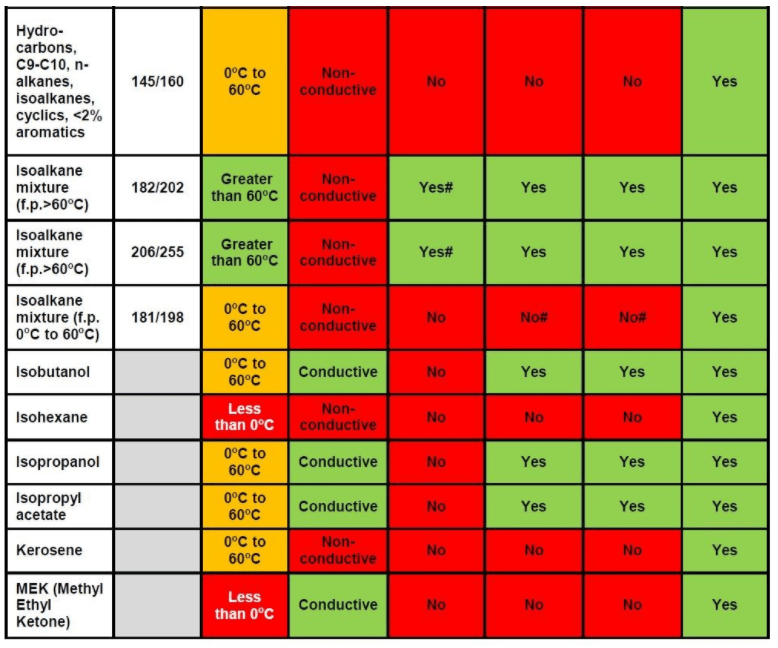

Based on the criteria in the SIA Guidance Note 51, example solvents have been tabulated against their recommended IBC types according to flash point and conductivity group.

Please visit the SIA website (https://www.solvents.org.uk/) for the full detailed listing. See extracts below:

Table 3: Recommended IBC Type Selection According to Solvent, Flash Point & Conductivity Group

(Editors note: From the above extract, stainless steel IBCs have been recommended for all except three solvents listed)

IBC Heaters | Insulated Heating Jackets For IBC Containers | Thorne & Derrick International are the UK’s Specialist Distributor of Drum & IBC Heating Equipment to diverse industries including process, food and beverage, confectionery, manufacturing, chemicals, pharmaceutical and utilities.

Thorne & Derrick are leaders in ATEX & IECEx Product Innovation providing Lighting, Heating, Ventilation and Security in Explosive Atmospheres.

Talk to us today about how we can improve operational safety, energy efficiency and optimise productivity in your hazardous areas.

We are your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for your UK and international projects.

>>> GO TO INNOVATION <<<

EXPERTS IN EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Since 1985, T&D have established a solid reputation based on Service, Integrity and Trust.

From our distribution locations with 50,000+ sq feet warehouse capacity and a £2.5 million stock, we can supply many products by next day delivery – our key sectors are the process, pharmaceutical, chemical, utility, food/beverage, renewable and oil/gas industries.