How To Install Trace Heating | Beginner’s Guide To Trace Heating System Installation

Published 30 Apr 2025

Knowing how to install trace heating correctly is crucial for ensuring system performance, safety, and compliance—especially in industrial environments where downtime and failures can be costly. Whether you’re working in oil and gas, chemical processing, food production, or utilities, this guide will walk you through the key steps and considerations when installing trace heating systems.

We’ll also answer related questions such as:

-

How does trace heating cable work?

-

What does a trace heating system look like?

-

What are the different types of heating cable installations?

If you’re looking for information on how to install trace heating, or even asking how to install heat tracing, you’re in the right place—these are simply interchangeable terms referring to the same process: applying electrical heating cables to pipes, tanks, or equipment to prevent freezing or maintain process temperatures.

Need to know more about How To Install Heat Trace from the experts and determine whether it’s essential for your business?

How Does Trace Heating Cable Work?

Before diving into installation, it helps to understand what is trace heating? how do trace heating cables work?

Trace Heating cables—also known as heating cables or heating tapes—generate heat through electrical resistance. They’re installed along the length of a pipe, tank, or valve and are typically controlled via a thermostat or controller that regulates temperature to prevent overheating or inefficiency.

There are several types of Tracing cables:

-

Self-Regulating Trace Heating Cables: Adjust their heat output depending on surface temperature.

-

Constant Wattage Trace Heating Cables: Deliver a fixed amount of heat across their length.

-

Mineral insulated Trace Heating Cables: Durable, high-temperature cables used in demanding industrial environments.

When installed properly, trace heating systems offer years of safe, efficient performance.

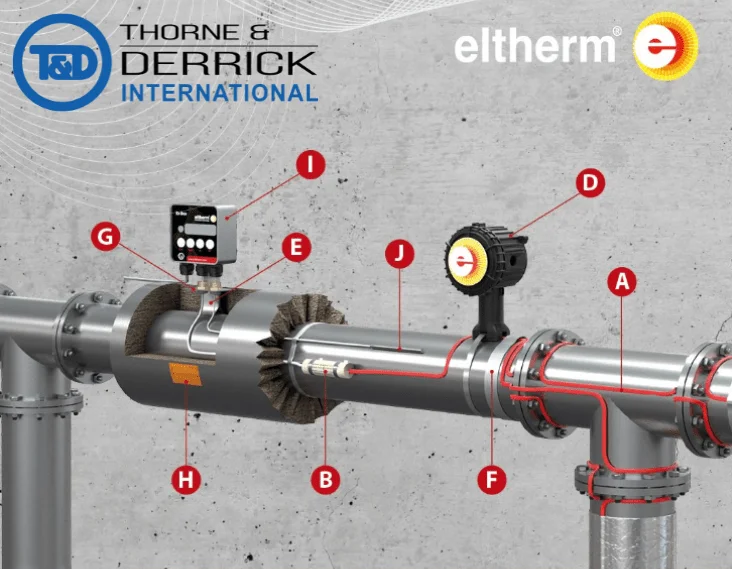

What Does a Trace heating System Look Like?

A fully installed industrial trace heating system includes:

-

Heating Cable: Installed directly on the pipe or equipment.

-

Power Connection Kits: Connect the cable to a power supply.

-

End Seals: Protect the cable end from moisture and damage.

-

Temperature Controller/Thermostat: Monitors and controls heat output.

-

Thermal Insulation: Minimises heat loss and protects the cable.

-

Warning Labels: Indicate the presence of a trace heating system for safety and compliance.

In some cases, you’ll also find junction boxes, circuit breakers, and monitoring systems—especially in larger or hazardous area installations.

Step-by-Step: How to Install Trace Heating

The following installation process is designed for industrial trace heating applications and assumes the use of self-regulating or constant wattage cables.

1. Plan the System Layout

-

Survey the site to determine pipe lengths, valve positions, and fittings.

-

Identify power source locations and determine circuit lengths.

-

Perform heat loss calculations to determine cable type, wattage, and number of circuits.

Tip: Consult with one of our trace heating specialists or use manufacturer-specific layout design software.

2. Prepare the Pipe Surface

-

Clean the surface of the pipe or equipment to remove oil, dust, or rust.

-

Ensure that all sharp edges or burrs are removed to avoid damaging the cable.

-

Dry the surface completely before applying heating cable.

3. Install the Heating Cable

-

Lay the trace heating cable along the bottom 4 or 5 o’clock position of the pipe for efficient heat transfer.

-

For larger pipes or higher wattage needs, spiral or multiple parallel runs may be required.

-

Do not overlap the heating cable unless the cable is rated for overlap (only certain self-regulating cables are).

-

Use approved fixing tape or cable ties at regular intervals—do not use metal straps or wire that could damage the cable.

4. Install Power and End Terminations

-

Use manufacturer-supplied power connection kits to safely terminate cables.

-

End seals are critical for preventing moisture ingress and ensuring system integrity.

-

Follow manufacturer instructions exactly—especially for hazardous area (ATEX/IECEx) installations.

5. Install Temperature Control

-

Mount the thermostat or controller near the heat-traced line or on a representative pipe section.

-

Insert the temperature sensor under insulation and as close as possible to the pipe surface.

-

Ensure sensors are properly secured and protected.

6. Apply Thermal Insulation

-

Wrap the traced pipe or equipment with approved insulation—usually mineral wool, foam glass, or closed-cell foam depending on the environment.

-

Add a vapor barrier or jacket if exposed to moisture or outdoor conditions.

-

Secure insulation tightly and ensure no air gaps between the heating cable and the pipe surface.

7. Label and Document

-

Apply trace heating warning labels at regular intervals on the insulation (every 3–5 metres).

-

Update your facility’s documentation with:

-

Cable routing diagrams

-

Circuit IDs and locations

-

Power consumption data

-

Inspection records

-

8. Test the System

-

Perform continuity and insulation resistance tests before energising.

-

Use a megohmmeter to verify insulation resistance exceeds manufacturer minimums.

-

Once tested, energise the system and monitor for proper heating and control.

Bonus: Key Installation Tips

-

Avoid bending heating cables beyond the minimum bend radius.

-

Never install a damaged or cut cable—replace immediately.

-

Protect exposed ends and terminations from water ingress at all times.

-

Always follow local electrical codes and consult qualified electricians for high-voltage or hazardous-area work.

FAQs

Can You Install Trace Heating Yourself?

In residential or commercial applications, it may be possible. However, for industrial systems, a qualified technician or electrician is recommended—especially for high-voltage systems, hazardous areas, or critical process lines.

How Long Does It Take to Install Trace Heating?

A typical industrial installation can range from a few hours for a small skid-mounted system to several days or weeks for a large facility, depending on pipe lengths, complexity, and environmental factors.

Is Trace Heating Cable Safe?

Yes—when installed correctly, trace heating cable is extremely safe and reliable. Self-regulating cables prevent overheating, and industrial systems include safeguards such as circuit protection, thermal controllers, and insulation.

Need A Trace Heating Solution?

With more than four decades of industry expertise, Thorne & Derrick are recognised leaders in delivering specialist trace heating solutions for a wide range of industrial applications. From hazardous zones and extreme climates to critical process control systems, we design bespoke solutions tailored to the specific needs of your operation and can provide crucial knowledge on how to install trace heating systems.

Our services include comprehensive in-house heat loss analysis, system design, and technical specification, backed by a commitment to engineering excellence. Using only premium, market-leading trace heating cables and components, we provide cost-effective systems that enhance operational efficiency, minimise downtime, and support long-term project reliability—from initial concept through to full commissioning.

Thorne & Derrick are the UK’s largest stockist and supplier of Trace Heating products, including ATEX Heat Tracing Cables, Heated Hoses, Heating Mats & Jackets, Drum Heaters, IBC Heaters & more.