SICK LBV301 Level Sensors – ATEX Hazardous Area

SICK SENSORS

SICK LBV301 Level Sensors

- Compact sensor from 1″ thread

- Monoprobe design prevents bulk materials from sticking or jamming

- Polished monoprobe for food applications

- Commissioning without filling and medium calibration

- Process temperature up to 250 °C

- ATEX certifications (1D/2D/1G/2G) available

- Tube extension variant (LBV331) up to 6 m and cable extension model (LBV321) up to 80 m available for vertical mounting

SICK LBV301 Level Sensors – BENEFITS

- Easy commissioning, no upstream calibration necessary

- Maintenance-free system

- Sensors can be tested while installed

- Flexible, reliable system suitable for many types of applications

- Vertical mounting, even in difficult installation and ambient conditions

SICK LBV301 Level Sensors are suitable for hygienic applications as they have a wide range of process connections and several electronic variants making this level sensor suitable for many applications including those in hazardous areas. The monoprobe is easy to clean making the LBV301 sensors suitable for use in the food industry.

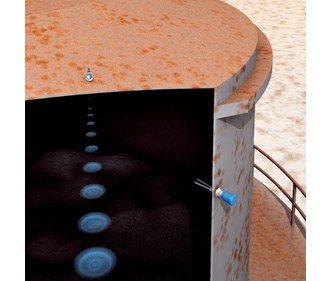

The vibrating level switches in the LBV301 range can be relied upon to signal full, empty, or demand states in bulk materials. The monoprobe design prevents bulk materials from jamming. The rugged stainless steel sensor design is piezo-electrically energized

ATEX Hazardous Area Level Sensors – SICK

SICK Level Sensors – Continuous Level Measurement & Point Level Measurement

SICK LBV301 Level Sensors – ATEX Hazardous Area – TECHNICAL DATA

| Measurement principle: | Vibrating level switch |

| Detection principle: | Contact |

| Medium: | Bulk solids |

| Measurement: | Switch |

| Process temperature: | –50 °C … +150 °C |

| Process pressure: | –1 bar … 16 bar |

| Output signal: | Non-contact switch, Double relay (DPDT, 1 x PNP/NPN, NAMUR signal |

| Accuracy of sensor element: | ± 10 mm |

Bulk solid LEVEL SENSOR APPLICATIONS

SICK LBV301 Level Sensors enables level measurement and point level measurement of solids.

- Level measurement of pellets or wood chips in the wood industry

- Detection of basic substances in the food industry, such as milk powder

- Min./max. or demand signal in silos

- Explosive dust mixtures

Level measurement of carbon in Tank at a blast FURNACE

Carbon injection into a blast furnace is an important procedure in the iron making process. Disturbances of carbon’s continuous feed can have consequences on production and iron quality.

Either a vibrating level switch such as the LBV301 or a non-contact ultrasonic level sensor can be installed directly in the silo to provide exact carbon levels.

➡ Did you know? T&D Hazardous Area team are trained and certified in the specification and sale of flameproof and explosion-proof equipment, including Crowcon Gas Detectors.