Fisher CV500 Eccentric Plug Valve – Rotary Valves

Fisher CV500 Eccentric Plug Valve – Rotary Valves

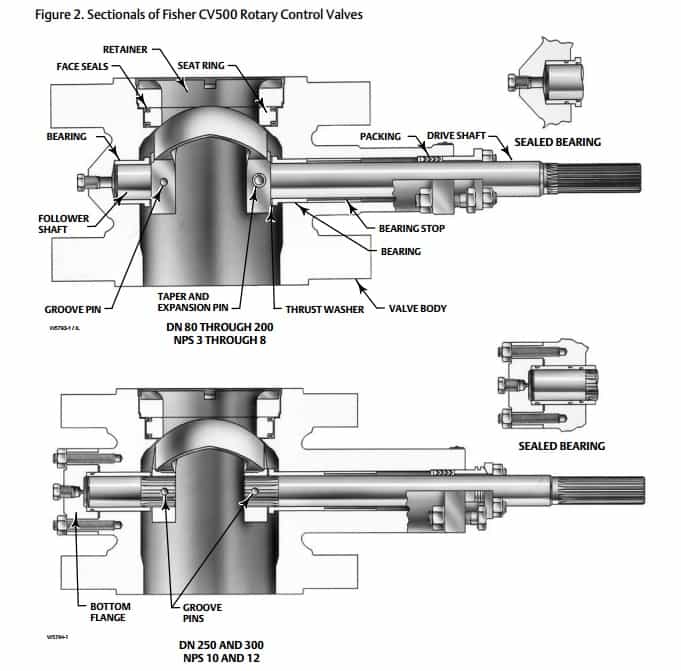

Fisher CV500 Valve is a flanged or flangeless eccentric plug valve with reversible metal seat ring and splined shaft. The CV500 combines the rangeability of the cammed-segmented V-notched ball, with the inherent ruggedness found in the V500 heavy duty bearings, seals and body making it suitable for the pressure control for gas and liquids.

The flanged CV500 valve features streamlined flow passages, rugged metal trim components, and a self-centering seat ring.

The Fisher CV500 valve dependably controls fluids in many process industries as the flow design provides high capacity for gas, steam, liquids, or fibrous slurries.

Fisher CV500 Eccentric Plug Valve – Product Features

- Excellent Flow Characteristic – precise contouring of V-notch ball provides a modified equal percentage flow characteristic

- High Capacity – unrestricted, straight-through, flow design provides greater capacity than many conventional globe and rotary eccentric plug valves

- Long Seat Life– patented V-notch ball cams into and out of the seat minimizing contact with the seat ring for reduced wear and friction. V-notch ball doesn’t contact seat during throttling operation. S31600 (316 stainless steel) or R30006 (Alloy 6) seat ring has two shutoff surfaces and can be easily reversed, reducing downtime

- One-Piece Body – valve body is cast in one piece. There are no body gaskets to leak as a result of pipeline stresses.

- Operational Versatility – self-centering seat ring and rugged V-notch ball allow forward or reverse flow with tight shutoff in either flow direction

- Easy Installation – integral valve flanges mate with many different classes of pipeline flanges, satisfying a variety of piping requirements. Flanges eliminate exposed line flange bolting, shorten alignment and installation time, and promote secure valve installations and piping integrity. Flangeless valves are automatically self-centering on line bolting for easy installation

- Simple Assembly and Maintenance – no special orientation, precision clamping or repetitive centering of V-notch ball and seat ring is required when tightening the retainer, promoting accurate alignment and easy assembly

- Sour Service Capability – trim and bolting materials are available for applications handling sour fluids and gases. These constructions comply with the requirements of NACE MR0175-2002

- Rugged Construction – durable, solid metal seat ring and ball shut off tightly. Oversized shaft diameters and rugged trim parts allow high pressure drops

- Reliable Performance – patented seat ring design self-centers, self-laps, and dynamically aligns with V-notch ball, giving superior cycle life. Optional sealed metal bearings help prevent particle buildup and valve shaft seizure in severe applications

FISHER CV500 ECCENTRIC PLUG VALVE

PRODUCT Specification

| Available Valve Configurations | Flanged valve body assembly with reversible(1) metal seat ring and splined shaft |

| Valve Body Sizes | NPS 3, 4, 6, 8, 10, and 12. DN 80, 100, 150, 200, 250 and 300 are also available. End |

| End Connection Style | Raised-face flanges or ring-type joint flanges (ASME B16.5). Valve bodies with EN PN10 through PN100 flanges also available. |

| Maximum Inlet Pressure(2) | Consistent with applicable ASME or EN flange ratings |

| Shutoff Classification | Class IV per ANSI/FCI 70-2 and IEC 60534-4, (0.01% of valve capacity at full travel) for either flow direction |

| Flow Characteristic | Modified equal percentage |

| Flow Direction | Forward (normal) flow is into the convex side of the V-notch ball Bidirectional flow is into either side of the V-notch ball |

| Flow Coefficient Ratio(3) | 200 to 1 |

| Actuator Mounting | Right-hand or left-hand as viewed from the upstream side of the valve. Mounting position depends on the desired open valve position and flow direction required by operating conditions. For more information, see the Installation section. |

| Valve V-Notch Ball Rotation | Counterclockwise to close (when viewed from the actuator side of the valve body) through 90 degrees of V-notch ball rotation |

| Valve Body/Actuator Action | With diaphragm or piston rotary actuator, field-reversible between push-down-to-close (extending actuator rod closes valve body) and push-down-to-open (extending actuator rod opens valve body) |

| Options | Sealed bearing constructions, purged bearings |

1. The reversible seat is not available in every trim material. 2. The pressure or temperature limits in the referenced tables or figures, and in any applicable code limitation, should not be exceeded. 3. Ratio of maximum flow coefficient to minimum usable flow coefficient. May also be called rangeability

| Valve Size NPS | Flanged | ||

| CL150 | CL300 | CL600 | |

| DN | kg | ||

| 80 | 19 | 24 | 26 |

| 100 | 36 | 42 | 50 |

| 150 | 54 | 69 | 93 |

| 200 | 79 | 98 | 135 |

| 250 | – | 208 | – |

| 300 | – | 253 | – |

| NPS | Pounds | ||

| 3 | 42 | 52 | 57 |

| 4 | 79 | 93 | 111 |

| 6 | 120 | 152 | 204 |

| 8 | 175 | 217 | 298 |

| 10 | – | 458 | – |

| 12 | – | 558 | – |

Fisher CV500 Eccentric Plug Valve – Rotary Valves

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Installing Fisher CV500 Eccentric Plug Valve

Fisher CV500 eccentric plug valves may be installed in any position. However, for best shutoff performance, a position with the shaft horizontal is recommended.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.