Fisher V260 Full Bore Pipeline Ball Valve – Rotary Valves

Fisher V260 Full Bore Pipeline Ball Valves – Rotary Valves

Fisher V260 Valve is a flanged full bore pipeline ball valve designed from the ground up with features for optimized pressure, flow and process control. The V260 valve has integral drilled attenuator that controls noise and vibration from high pressure drop liquids and gases. The splined shaft connection to the actuator reduces lost motion. The valve can be ordered with Aerodome or Hydrodome attenuators for noise reduction.

The V260A with Aerodome attenuator, V260B with Hydrodome attenuator, and V260C Ball Control Valves combine the efficiency of a rotary valve with the energy-dissipating capability of a special trim to provide improved performance for demanding applications.

The V260 full-bore ball valve is available with composition seals, and process type stem packing for improved service life.

Fisher V260 Full Bore Pipeline Ball Valve – Product Features

- Excellent Flow Control – the splined ball to shaft connection, splined shaft to actuator connection, double power-end bushing assemblies, and trunnion guiding, all provide improved dynamic control

- Aerodynamic Performance – up to -20 dBA acoustical attenuation can be achieved for the V260A within a single stage construction. Dual-stage construction can provide up to -25 dBA attenuation

- Improved Service Life – the attenuator is an integral part of the seal assembly. The seal wipes to ball surface, not the attenuator, promoting increased service life

- Trim Versatility – key valve components, such as valve body, ball, shaft and bearings, are interchangeable between the Design V260A, V260B and V260C. This feature allows you to reduce your spare parts inventory and maintenance time

- Sour Service and Sour Crude Oil Capability – optional materials are available that comply with NACE Standard MR0175-2002

- Tight Shutoff – self-adjusting seal(s) that are pressure assisted provide tight shutoff for long reliable service. The design incorporates a heavy duty S31600 stainless steel carrier that retains the composition seal for full-rated pressure drop service

- Heavy Duty Trunnion – the ball trunnions are designed for demanding applications requiring long service life, with a reduction in maintenance time and costs

- Broad Hydrodynamic Applications – single, dual, and three-stage attenuators for the V260B may be provided for a varying range of applications. A Kc value of 1.0 is achievable depending on service conditions

- Flexible Applications – the attenuator is active throughout the ball rotation for very demanding services or a characterized attenuator is used to match the service conditions

FISHER V260 FULL BORE PIPELINE BALL VALVE

PRODUCT Specification

| Valve Body Sizes | NPS J 8, J 10, J 12, J 16, J 20, and J 24 flanged valves with CL150, CL300, or CL600 raised-face flanges compatible with ASME B16.5. |

| Maximum Inlet Pressure(1) | Consistent with CL150, CL300, or CL600 pressure-temperature ratings per ASME B16.34 |

| Maximum Allowable Shutoff Pressure Drop(1) | For Single-Seal and Dual-Seal Construction (Except where further limited by the pressuretemperature rating of the valve body): J CL150: 20 bar (285 psi) at 38_C (100_F) J CL300: 51 bar (740 psi) at 38_C (100_F) J CL600: 103 bar (1480 psi) at 38_C (100_F) |

| Shutoff Classification | Single-Seal Composition Constructions: 0.001% of maximum valve capacity (less than 10% of ANSI/FCI 70-2 Class IV and IEC 60534-4) Dual-Seal Composition Constructions: 0.001% of maximum valve capacity (less than 10% of ANSI/FCI 70-2 Class IV and IEC 60534-4) |

| Seal Material Temperature Capability(1) | Seal Material and Temperature Capability(1) Standard: J POM (polyoxymethylene) -29 to 82_C (-20 to 180_F) Optional: J PTFE/PEEK(2)(3) -29 to 93_C (-20 to 200_F) |

| Flow and Shutoff Direction | Unidirectional flow for V260 is forward flow. Seal is upstream. J Single Seal Constructions: Should be used for unidirectional flow and unidirectional shutoff only. J Double Seal Constructions: V260A and V260C may be used for unidirectional and bidirectional flow. V260B should be used for unidirectional flow only for effective anti-cavitation protection. Bidirectional shutoff requires the dual seal construction |

| Flow Characteristic | Modified linear with single high density attenuator, J Modified equal percentage with single characterized attenuator, or J Modified equal percentage without attenuator |

| Maximum Ball Rotation | 90 degrees |

| Actuator Mounting | Right-hand or left-hand mounted as viewed from the valve inlet for forward flow |

| Options | J Double block-and-bleed applications (Dual-seal construction is required), J Two Stage V260A Attenuator, J Two or Three Stage V260B Attenuator, J CL900 flanges, J Ring type joint flanges |

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation for this valve should not be exceeded. 2. PTFE stands for Polytetrafluoroethylene, and PEEK stands for PolyEtherEtherKetone. 3. Temperature limit of PTFE/PEEK is limited due to standard Nitrile O-Ring. Contact your Emerson Process Management sales office for higher temperature options, up to 232_C (450_F).

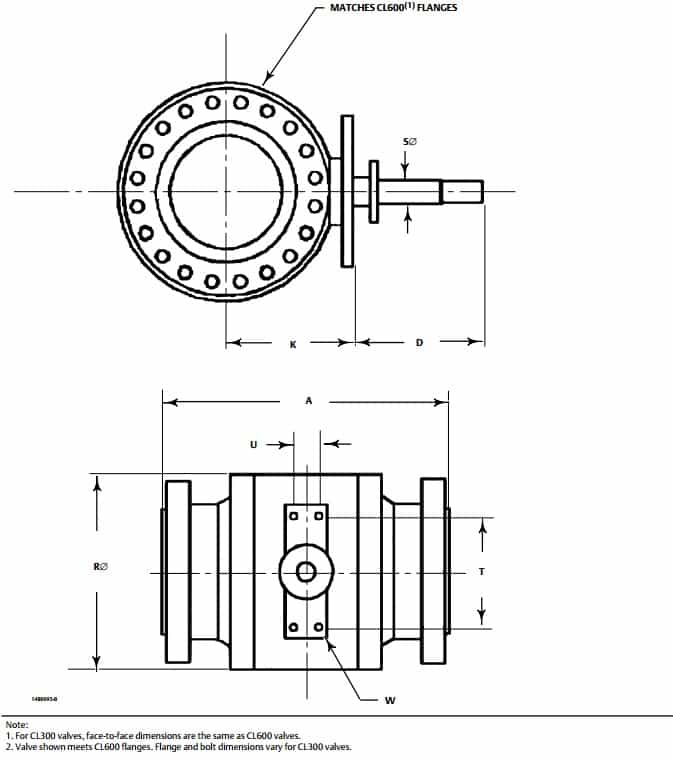

| Valve Size, NPS | A | D | K | RØ | SØ | T | U | W (Threaded) | Approximate Weight | |

| Shaft Diameter | Spline Diameter(1) | |||||||||

| mm | kg | |||||||||

| 8 | 661 | 356 | 273 | 457 | 44.4 | 44.4 | 273 | 51 | 3/4-10 | 442 |

| 10 | 788 | 324 | 553 | 63.5 | 63.5 | 337 | 76 | 7/8-9 | 703 | |

| 12 | 840 | 369 | 639 | 919 | ||||||

| 16 | 991 | 508 | 508 | 848 | 76.2 | 76.2(1) | 533 | 127 | 1-1/4-8 | 2472 |

| 471 | 76.2 | 63.5(2) | ||||||||

| 20 | 1194 | 508 | 602 | 1040 | 8.9 | 88.9(1) | 4309 | |||

| 471 | 8.9 | 63.5(2) | ||||||||

| 24 CL150 | 1397 | 314 | 671 | 1158 | 8.9 | 88.9 (keyed shaft) | 533 | 127 | 1-1/4-8 | 5352 |

| 24 CL300 | 1397 | 508 | 708 | 1158 | 8.9 | 88.9 | 533 | 127 | 1-1/4-8 | 5761 |

| 24 CL600 | 1397 | 364 | 708 | 1158 | 102 | 102 (keyed shaft) | 610 | 457 (U1)(3) 254 (U2)(3) | 1-1/4-8 | 7076 |

1. For 1069 size 100 actuator. 2. For 1061 size 100 actuator. 3. See table 6 for NPS 24 U1 and U2 information

Fisher V260 Full Bore Pipeline Ball Valve – Rotary Valves – Dimensions

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Installing Fisher V250 Full Bore Pipeline Ball Valve

Fisher V250 full bore pipeline ball valve may be installed in any position. However, the recommended orientation is in a horizontal pipeline with the shaft positioned horizontally and the ball closing in the downward direction.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.