T&D Solves Heated Storage Challenge in Explosive Atmosphere

Published 15 Jul 2025

ATEX Heated Storage Container

A turnkey hazardous area heating solution for safe chemical storage – from concept to completion

Thorne & Derrick delivered a fully bespoke ATEX certified heated storage container to a multinational biotechnology company, enhancing safe, compliant, and energy-efficient heated chemical storage in a hazardous environment. This complex and fully compliant solution replaced an outdated boiler system.

Background & Client Challenge

- Client: Multinational biotechnology firm operating in scientific research, healthcare, pharmaceutical, and laboratory equipment sectors

- Challenge: The client relied on an ageing exterior structure with radiators powered by a boiler system to heat chemical barrels and IBCs. Rising energy costs and structural deterioration necessitated a modern, compliant, and energy-efficient replacement

- Objective: Develop a solution for safe storage and heating of diverse temperature-sensitive chemicals, compliant with hazardous area regulations

Solution Development

Through proactive outreach, Thorne & Derrick engaged with the client, leading to a site visit to assess the situation. Recognising the client’s need for a modern electrical solution, Thorne & Derrick spearheaded the design and delivery of a fully bespoke heated storage container. Thorne & Derrick worked together with several supply chain partners to design and deliver a temperature controlled storage unit including the use of latest fan heater technology from EXHEAT.

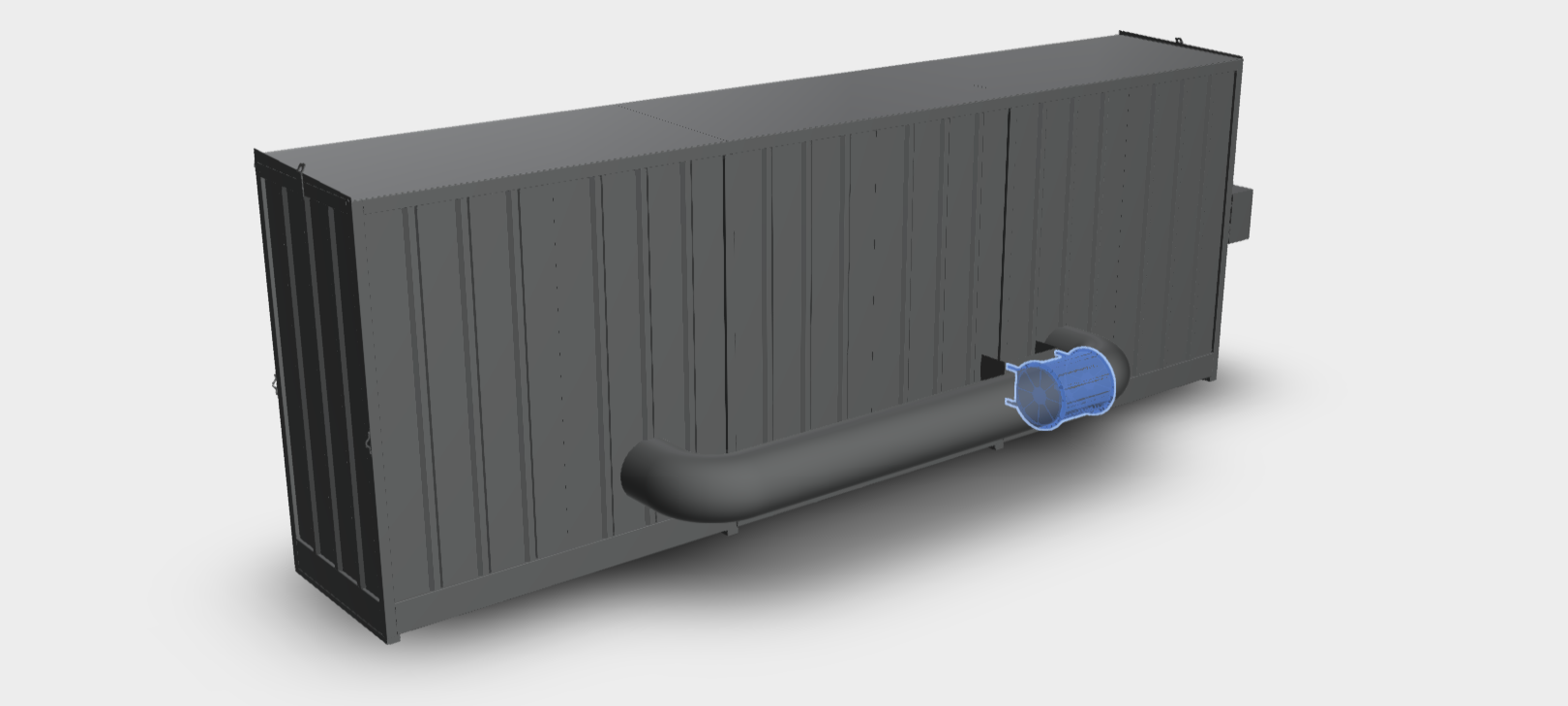

The client required a container with a capacity of 48 barrels or 12 IBCs. The challenge was to provide a controlled heating solution that could heat up and maintain ambient temperatures as per the chemical manufacturers guidelines.

Compliance & Testing

A full Factory Acceptance Test (FAT) was conducted, with the client’s engineers attending site to inspect and sign off the solution prior to delivery. This ensured full satisfaction with the build quality, safety features, and operational readiness.

Technical Highlights

- EXHEAT LFH Fan Heater

- Custom Temperature Control Panel

- ATEX/IECEx certified components throughout

- Designed for safe temperature control storage of up to 50 different chemicals

Product Focus

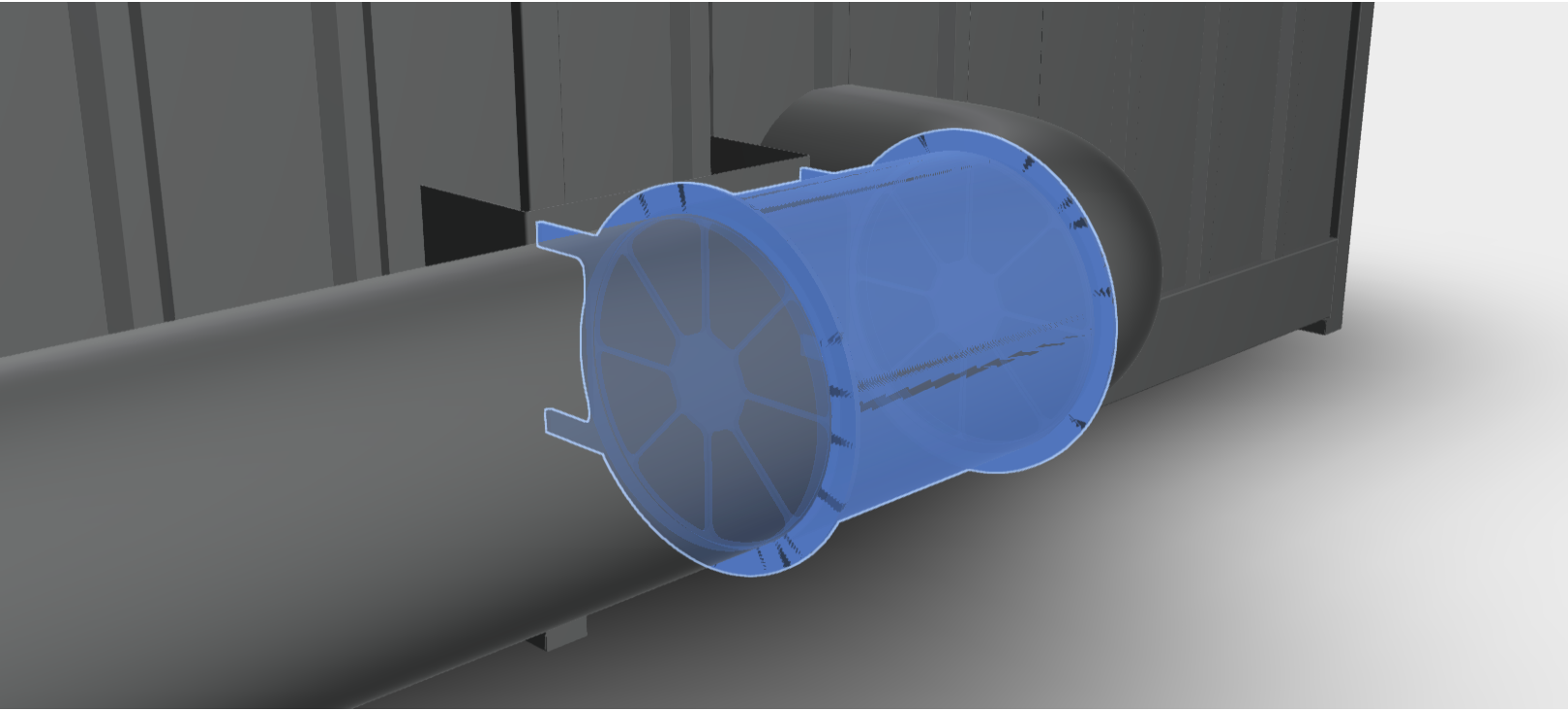

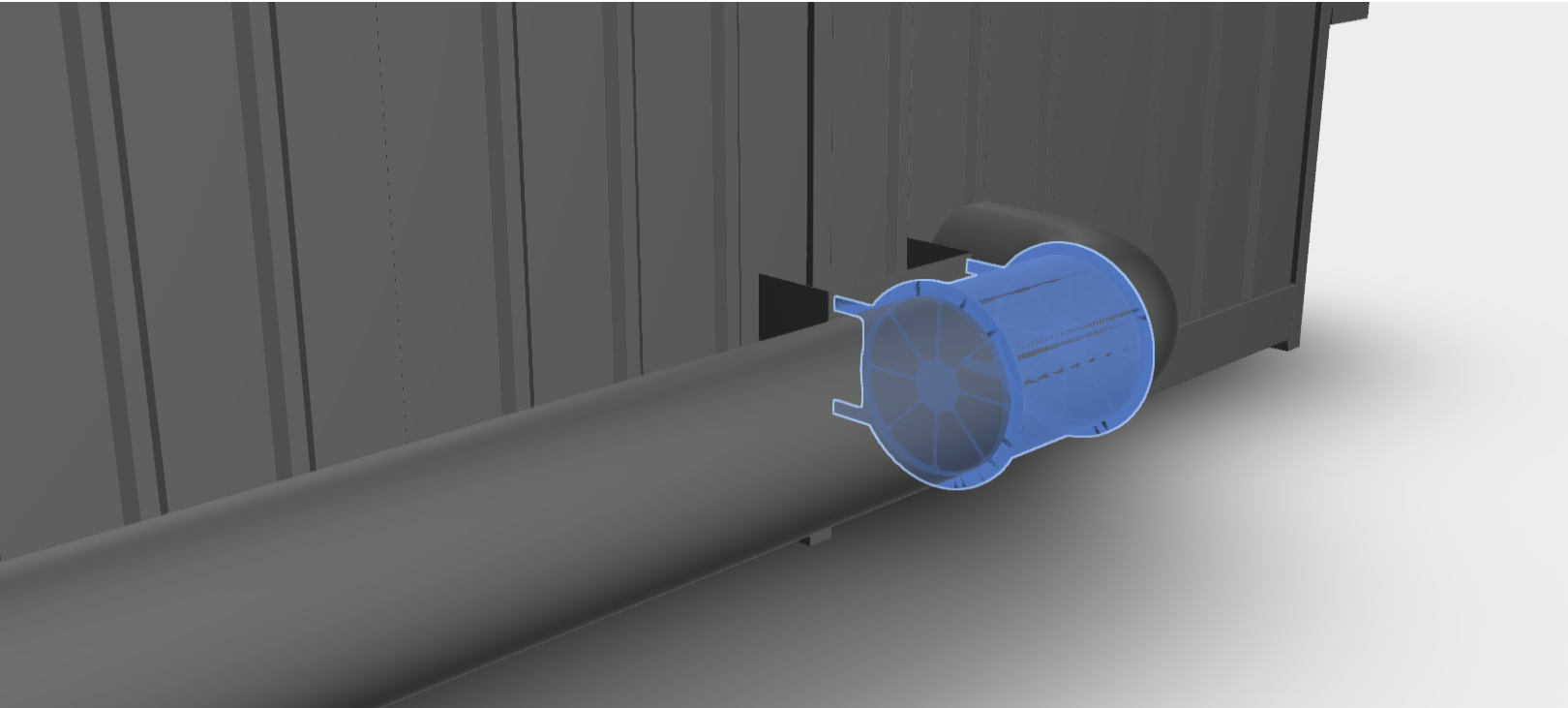

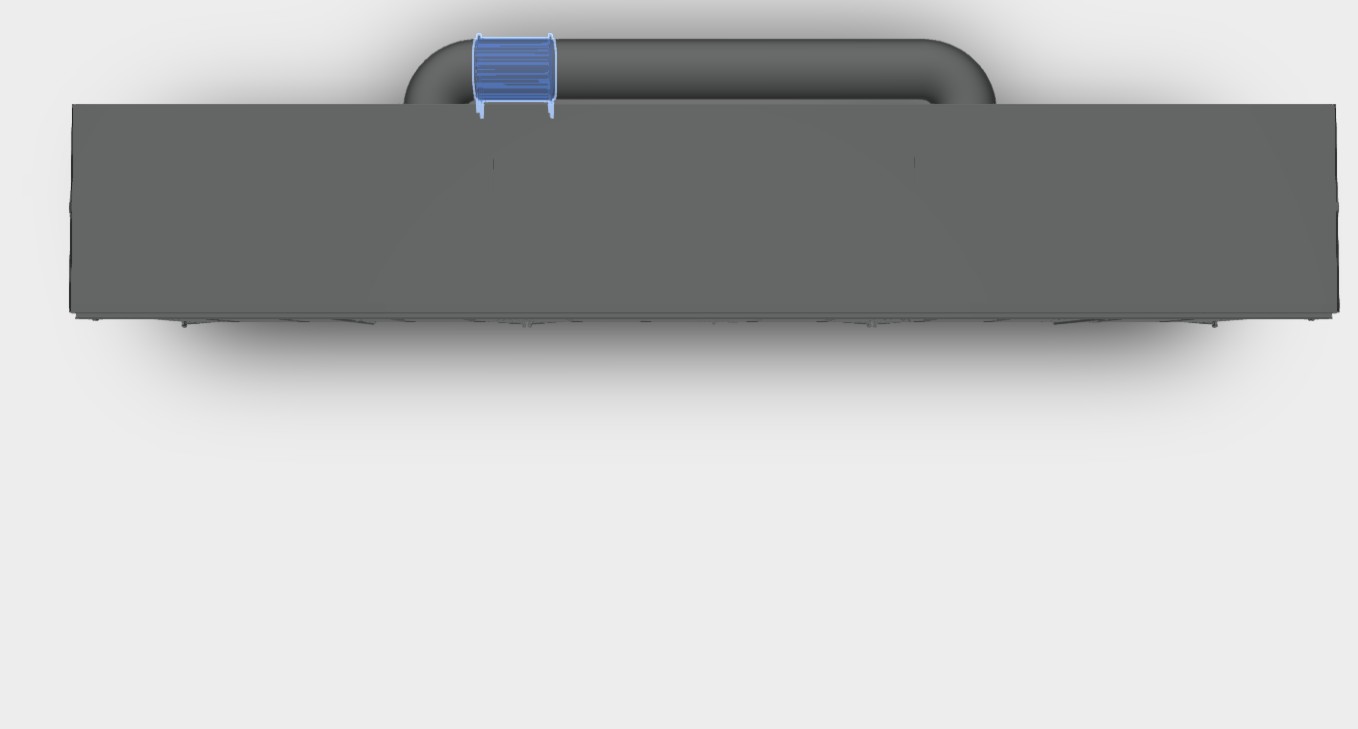

A critical component of the build, the EXHEAT LFH was selected as the only ATEX-certified fan heater on the market approved for use with rigid front and rear ducting. This unique design was essential in satisfying the client’s strict safety requirements for hazardous area operation. The LFH enabled safe, controlled warm air distribution within the container, while its robust, compact design and proven reliability made it the optimal choice for this application.

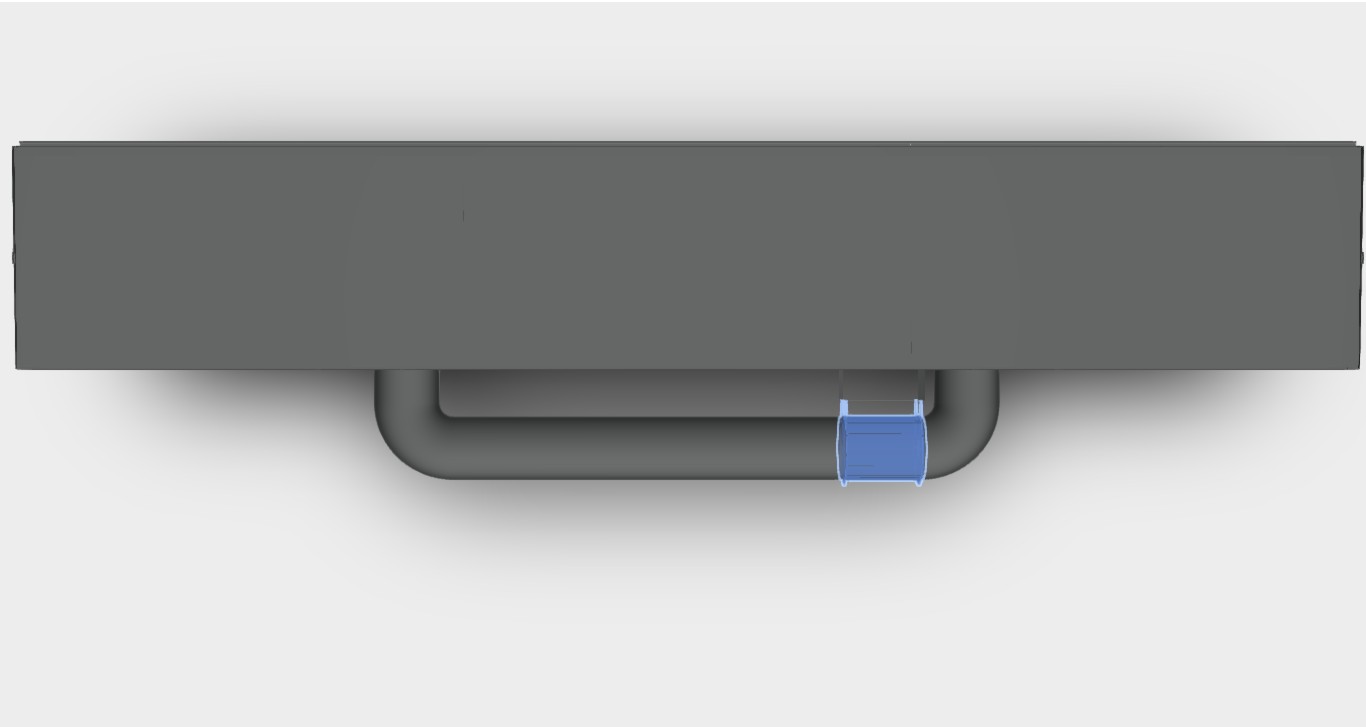

The heater has a built in safety features including an automatic over-temperature cut out. Additionally ambient temperature control for low and high temperature alarms was built into the control system. Further the system was designed for the fan to run constantly and ensure even air circulation and thermal consistency. To maximise space internally the heater was fitted to the rear of the container which also provided easy access for maintenance.

Close up of LFH Fan Heater by EXHEAT

LFH Fan Heater Fitted to Back of Bespoke Heated Cabinet

Bespoke Heated Cabinet – LFH Fan Heater

Aerial View of LFH Fan Heater

Aerial View of LFH Fan Heater

Alternative View of EXHEAT LFH Heater

Fully custom-built solution designed for hazardous area chemical storage. Features include ATEX-certified fan heater with rigid ducting, custom control panel, and optimised internal layout to store up to 48 barrels or 12 IBCs safely and efficiently.

Results & Benefits

- Fully compliant heated storage solution which meets hazardous area requirements

- Replaced outdated boiler system

- Delivered a safer and more energy-efficient solution

- Significant increase in chemical storage capacity

- Collaborative delivery through a trusted supply chain network

Project Snapshot

| Client | Multinational Biotech Firm |

| Sector | Pharmaceutical |

| Solution | Bespoke ATEX Certified heated storage container |

| Heating System | EXHEAT LFH fan heater |

| Capacity | Up to 48 barrels or 12 IBCs |

| Timeline | ~12–16 weeks |

From Concept to Completion

What began as a conversation and a client idea was brought to life through engineering collaboration, application expertise, and a robust supply chain.

Conclusion

This project exemplifies Thorne & Derrick’s capabilities as solution sellers—taking a complex challenge from idea to installation, delivering compliance, safety, and operational excellence in hazardous area environments. From initial consultation to final commissioning, Thorne & Derrick is your trusted partner in EX-rated heating innovation.

Looking for a Bespoke EX-Rated Heating Solution?

Get in touch with our experts to learn how we can help. Whether you need to safely heat chemicals, prevent product freezing, or maintain critical temperatures in a hazardous area, Thorne & Derrick can deliver a fully compliant, end-to-end solution tailored to your operational needs.