Heated Hose

Heated Hose For Frost Protection & Temperature Maintenance

Supplied by Thorne & Derrick | UK & Export Sales | Customer Service Excellence | ATEX & IECEx Compliant Solutions

Bespoke Hose Designs | 40+ Years Experience from Process Heating Specialists | CONTACT US

A heated hose is the ideal solution for the reliable transfer and transportation of liquids or gases without any loss of heat in both safe and hazardous areas. The maintain temperature required, power, application and outer protection material will determine the choice of hose. Typical applications include gas analysis, hot melt machines, bitumen transfer lines, heavy oil transfer and wax processing equipment.

➡️ For the heating and process temperature maintenance of pipework and mechanical services Thorne & Derrick stock and supply a complete range of heat trace cables and trace heating systems.

Gas substances are typically channelled between the measurement point and the analysis instrument in the analysis technique such as refineries, flue gas, mechanical engineering, chemical industry and the motor industry. For many applications the gas must have freeze protection, be protected against condensation or guarantee a constant temperature of up to 250°C.

A heated hose can be used to heat up, to prevent heat loss and to transport media such as grease, wax, oils, water, glue, foodstuffs etc – it is vital to keep these products in a liquid form.

Types Of Heated Hose

- Analyser Hoses – specified to provide temperature maintenance and frost protec tion up to 450° Celsius on hose diameters 4-10mm.

- Industrial Heated Pressure Hoses – to provide temperature maintenance and frost protection up to 250° Celsius on hose diameters 8-100mm.

All heated hoses are designed and produced specially to customer specifications – contact us with your requirement.

Controlled analytic hoses

This type of hose is installed to transport and transfer gaseous media from the point of withdrawal to an analytic measuring device – the hose is fixed-mounted in plants or in the form of portable systems.

Controlled Analytic Hoses

Heated Pressure Hoses

This type of heated hose provides process heating to maintain a constant temperature and transfer hose contents without heat loss – typical media include oil, wax, resin, tar, paint, grease, water, glue, plastic and foodstuffs.

Heated Pressure Hoses

Heated Analytic Hose – used in analyser technologies

Eltherm Hose Benefits

In order to meet the high standards Eltherm have set and to ensure optimum cable heating output on the carrier hose, the range of standard hoses are configured to include bifilar heated cables and special spacers.

Spacial density in the hose that carries the heating cable ensures perfectly homogeneous heat distribution throughout the hose in addition to optimum element loading.

The additional glass fibre spacer serves to prevent hot spots in moving applications with greater bending strain, as contact between the heating cables is avoided.

Other key advantages include:

- High power density resulting from tight winding of the heating cable with spacer

- Homogeneous and therefore optimal heat distribution

- Resistance to greater bending strain

- Longer service life and durability

- Very high quality standard

- Hot spot prevention

Hose Heating Applications

- hot melt machines

- wax transfer systems

- polyurethane foaming equipment

- insulated glass machinery

- gas analysis measuring equipment

- chemical dosing systems

- bitumen transfer

- heavy fuel oil systems

- food treatment and transfer

- packaging equipment

Flexible electrically heated hoses are used in a variety of applications across multiple sectors. Below are some examples

| FOOD | Heating chocolate, creams, jams, sugar molasses; Handling of glues/animal fats and of casein type; Introducing chocolate into moulds in the production of chocolates and similar products. |

| PHARMACEUTICAL / COSMETIC |

Maintaining the temperature of products that are affected by low winter temperatures. Examples: copolymer emulsions; sugar solutions; pharmaceutical mixtures; cosmetic mixtures; water (to prevent freezing) etc. |

| PRODUCTION OF ISOCYANATE/POLYOL DISTRIBUTION MACHINES |

The hose is used to keep the two substances at temperature and mix them. This tube is used in polyurethane production plants. |

| PACKAGING | Applications of hotmelt adhesives. Fields of application: packaging, publishing, woodworking industry, mattress manufacture. |

| CHEMICALS | Sampling and analysis of flue gases in thermal power plants and refineries. |

| POLYURETHANE | Application of polyurethane foams for packaging. |

| PAINTS/INSULATORS | Paint application; Application of insulation materials; Anti-abrasive material applications (e. g. in ship-building yards). |

| GLASS INDUSTRY | Industrial glass processing and, specifically, fields requiring pipes with medium/high operating pressures. |

| AUTOMOTIVE | Distribution of (hotmelt) adhesives for component assembly (also electrical components); Application of Polyurethane, Polyester, bi-component glues, highly-viscous adhesives. |

| MOLDING | Transport of polymers on blowing or extrusion machines in the thermoplastic material moulding industry. |

| OIL&GAS | Transfer of gases and vapours (e.g. in gas analysis units). |

| ROADWORKS | Transport of roadwork materials (e.g. tar) at high temperatures (over 250°C). |

Analytic Hoses

ELTHERM ELHa

Eltherm Analytic Heated Hose

Eltherm controlled analytic heated hoses serve to transport gaseous media from the point of withdrawal to the analytic measuring device. In most cases they are fix mounted in plants or in the form of portable systems.

One of their primary functions is in officially mandated emission monitoring in power stations or waste incineration plants. The range of Eltherm analytic hoses are also increasingly used in process analytics by various industries including petrochemical, oil and gas.

Key benefits of the Eltherm analytic heated hose include:

- Transport of gaseous media without loss of temperature

- Operating temperatures 5°C – 450°C

- Nominal hose widths: 2mm – 12mm

- Hose length: 0.3m – 150.0m

- Voltage: 12V – 400V

- Heat output optimised for each application

- Great heating circuit lengths

- Hose heating cables produced in-house

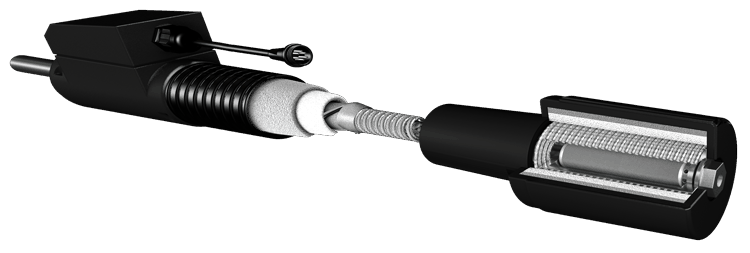

Eltherm Analytic Hoses Product Components

Analytic Heated Hose

Product Components

- Inner Liners – there are a range of liners available for the Eltherm analytic heated hose – these are chosen dependent on the temperature required.

- Sensor – temperature sensor is mounted between the inner lining and heating cable for temperature control. Additional sensors can also be mounted in any position required for further temperature detection and monitoring using the equipment.

- A – Heating cable – the resistance heating cable is produced in-house and is the basic heater element. The cables are insulated with fluoropolymer. 3.B – Spacer – the spacer is manufactured from braided glass fibre and provides reliable protection for the heating cable against damage and hot spots in the event of bending strain.

- Insulation – insulation depends on the maximum operating temperature and the selection of the heater outer jacket.

- Outer Jacket – selection is determined by the application, bend radius and ambient temperatures. The outer jacket provides heated hoses with reliable protection from humidity, weather and external environmental impact and mechanical strain.

- End caps – used to seal off both ends of the hose and the integrated strain relief provides reliable relief for the connecting cable.

- Connecting fitting – connection to the analyser or probe

- Connecting cables – by default, the connecting cable is led out separately.

➡ Read Blog: Flexible Heated Hoses For Analytic Gas Emission Applications

Electrical Heated Hose & Heated Sample Line – hose heating for greases, oils, waxes, resins, bitumen, varnish, water, CO2 carbon dioxide, foam plastics, glues and foodstuffs.

T&D can provide expert technical support and specification guidance for the selection of industrial and hazardous area heated hoses for onshore and offshore applications, contact us.