Fisher Eccentric Plug Valves

Fisher Valves

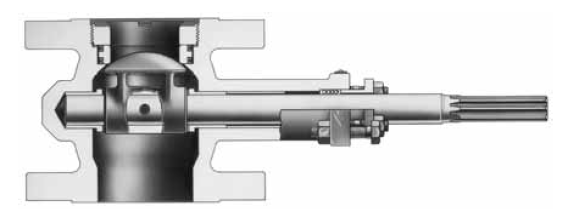

Fisher eccentric plug valves are a rotary valve featuring an eccentrically mounted plug or ball, which combines rotary valve efficiency with globe valve ruggedness.

Fisher V500 valve is designed and specified for severe and/or erosive service and features sealed bearings, an oversized one piece valve shaft and a variety of replaceable wear resistant trims ranging from stainless steel to ceramic.

Fisher CV500 valve features the equivalent ruggedness of Fisher V500 but uses a segmented ball as the control member rather than a plug.

CV500 has higher capacity than the V500 and features an equal percentage characteristic for better control performance.

Both of the eccentric plug valves feature a splined valve shaft, which provides zero lost motion when coupled to a Fisher rotary actuator.

Why FISHER ECCENTRIC PLUG Valves?

Eccentric Plug Valves Section

Eccentric plug valves resist erosion with rugged body and trim specified to withstand temperatures to 800°F (427°C) and shutoff pressure drops to 1500 psi (103 bar) – the path of the valve minimises contact with the seat ring during opening, reducing seat wear and friction while improving the throttling performance of the valve.

A segmented V-notch ball design can be produced to replace the plug for higher flow capacity applications.

Eccentric plug type rotary control valves are used for erosive, coking and “hard-to-handle” fluids in the petroleum refining, mining, power, paper and pulp industries.

Fisher Rotary Valves: Eccentric Plug, Butterfly, Segmented Ball & Full Bore Pipeline Ball Valves

Control valves are used in pipelines to provide flow, pressure, temperature and liquid level control of gases, steam, water, chemicals or hydrocarbons in industrial process and hazardous area located pipes. Complete specification, details and ordering information for Fisher Eccentric Plug Valves are available below.