Fisher Vee-Ball V200 Segmented Ball Valve – Rotary Valves

Fisher Vee-Ball V200 Segmented Ball Valve – Rotary Valves

Fisher Vee-Ball V200 Valve is a flanged segmented ball valve for throttling or on-off operation for many different applications in the process industries. The Fisher Vee-Ball V200 valve combines globe valve ruggedness with the efficiency of a rotary valve.

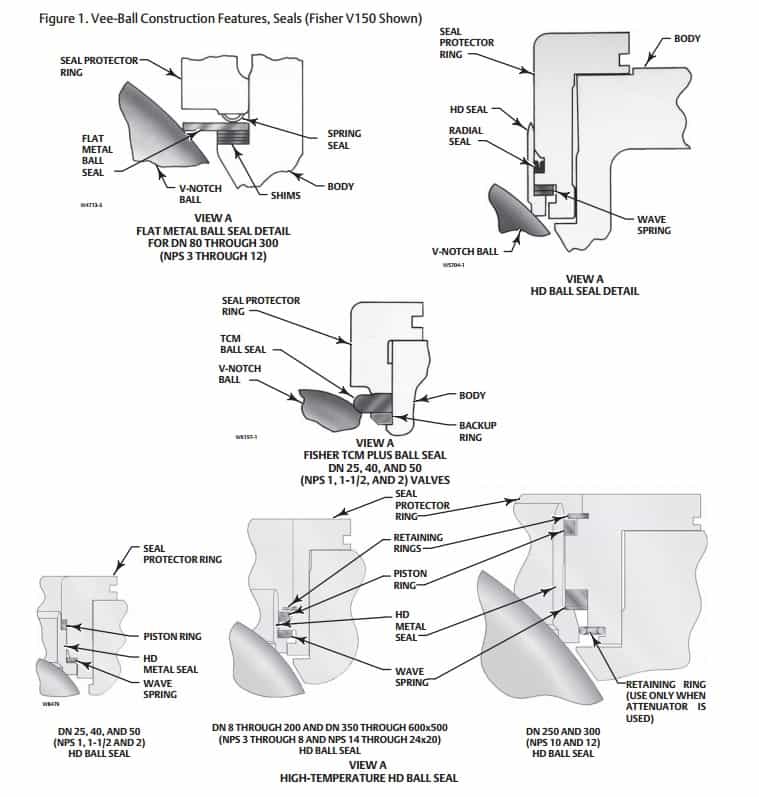

Fisher Vee-Ball V200 is a segmented ball valve which features a contoured segmented V-Notch ball. A shearing action between the V-notch ball and the ball seal promotes smooth, nonclogging operation.

The unrestricted straight-through flow design of V200 enables a high capacity for gas, steam, liquids, and fibrous slurries.

The flangeless V200 is available in NPS 1 through 8 in CL150, CL300, or CL600 and the NPS 10 is also available in CL150. The flanged V200 is available in NPS 2 through 8 in CL600RF and the trim components are interchangeable between the V150, V200 and V300.

Fisher Vee-Ball V200 Segmented Ball Valve – Product Features

- Trim Versatility – trim components are interchangeable between V150, V200, and V300 valves. This feature allows you to reduce your spare parts inventory and maintenance procedures. The seal assembly can be changed without removing the actuator or without removing the ball from the valve body

- Application Versatility– valves are available with ISA S75.04 and IEC 534-3-2 face-to-face dimensions as a standard construction, and optional ASME B16.10 short face-to-face dimensions. IEC 534.3.2 face-to-face dimensions are equivalent to S75.04 face-to-face dimensions

- Long Service Life – the solid HD metal seal construction provides long service life in demanding applications. The constant wiping action of the seal across the ball’s sealing surface prevents scale and sludge buildup, and provides excellent service on steam, gases, slurries, and various liquid applications

- Smooth Valve Operation – precision machined parts and pressure balanced seal designs allow smooth, precise movement of the ball

FISHER Vee-Ball V200 Segmented Ball Valve

PRODUCT Specification

| Valve End Connection Styles | V200: Flangeless (all sizes) and flanged valves that mate with CL600 raised-face flanges (NPS 2-8) |

| Maximum Inlet Pressure(1) | V200 WCC, CG8M, and LCC Valves: Consistent with applicable pressure-temperature ratings in table 1 per ASME B16.34. |

| Maximum Shutoff Pressure/Temperature Ratings(1) | Composition (Fisher TCM Plus or TCM Ultra), Flat Metal (NPS 3 through 12 valves only), HD and High Temperature HD Metal Ball Seals and Flow Ring |

| Shutoff Classification(1) | Fisher TCM Plus or Ultra Ball Seal (Forward Flow): Class VI per ANSI/FCI 70-2 and per IEC 60534-4, Flat Metal Ball Seal for NPS 3 through 12 only (Forward Flow): Class IV per ANSI/FCI 70-2 and per IEC 60534-4, HD (Heavy Duty) Ball Seal (Bidirectional Flow): 0.01% of valve capacity; Class IV per ANSI/FCI 70-2 and IEC 60534-4; Maximum allowable pressure drop in reverse flow is 6.9 bar (100 psi); High Temperature HD (Heavy Duty) Ball Seal (Bidirectional Flow): Class III per ANSI/FCI 70-2 and IEC 60534-4 Flow Ring Construction (Bidirectional Flow): 5% of valve capacity at full travel Micro-Notch Ball with HD Seal: 4 SCFH (Leakage rate equivalent to Class IV for standard ball. This is based on the capacity of a standard ball.) |

| Temperature Capabilities(1,2) | Composition Seals Fisher TCM Plus: -46 to 232C (-50 to 450F) Fisher TCM Ultra: -46 to 260C (-50 to 500F) HD Metal Seals: -46 to 288C (-50 to 550F) High Temperature HD Metal Seal: 288 to 427C (550 to 800F). Ceramic Micro-Notch Ball: -46 to 93C (-50 to 200F)(4) Flow Ring or Flat Metal Seal : -198 to 425C (-325 to 800F) PEEK/PTFE Bearings: -198 to 260C (-325 to 500F) |

| Flow Characteristic | Modified equal percentage |

| Optional Face-to-Face Dimensions | ASME B16.10 short face-to-face dimensions are available as an option for NPS 1 through 12 valves. Note that ASME B16.10 short dimensions are actually longer than ISA S75.08.02. |

| Standard Flow Direction | Forward (into the convex face of the V-notch ball) |

| Maximum Ball Rotation | 90 degrees |

| Actuator Mounting | Standard valve construction is for right-hand mounting, as viewed from upstream end of valve. Left-hand (optional) mounting is available upon request(5) |

| Valve Body/Actuator Action | With diaphragm or piston rotary actuator, the valve is field-reversible between PDTC or PDTO: push-down-to-close (extending actuator rod closes valve) and push-down-to-open (extending actuator rod opens valve) |

| Options | Pipe plug at end of follower shaft for all sizes, Line flange bolting, Materials that are compatible with sour service, Alloy construction materials, ENVIRO-SEAL packing system: ENVIRO-SEAL Packing Systems for Rotary Valves (D101638X012) for more information, Micro-Notch construction for NPS 1 valves, Alloy trim material , Chrome Carbide coated internals (NPS 2 through 12), Rotary attenuator to reduce aerodynamic noise and cavitation effects, Double D, Square, and Keyed shaft options |

1. The pressure/temperature limits in this bulletin, and any applicable code or standard limitation, should not be exceeded. 2. Additional limits are shown in tables 6, 7 and 8. 3. Ratio of maximum flow coefficients to minimum usable flow coefficient can also be called rangeability. 4. For the CG8M and alloy 6 Micro-Notch constructions, pressure and temperature capabilities are the same as for standard constructions. 5. True left-hand mount is not available for Micro-Notch constructions, as it will cause the ball to rotate to the bottom of the valve body

| Valve Size | V200 | |

| DN | NPS | kg |

| 25 | 1 | 4.5 |

| 40 | 1-1/2 | 6.4 |

| 50 | 2 | 10 |

| 80 | 3 | 15 |

| 100 | 4 | 22 |

| 150 | 6 | 36 |

| 200 | 8 | 62 |

| 250 | 10 | 114 |

| 300 | 12 | – |

| 350 | 14 | – |

| 400 | 16 | – |

| 500 | 20 | – |

| 600×500 | 24×20 | – |

Fisher Vee-Ball V200 Segmented Ball Valve – Rotary Valves – Valve Body Materials, End Connections, and Ratings

| Valve Design | Valve Body Material | Size | Ratings | |

| NPS/DN | ASME/PN | |||

| V200(4) | WCC, LCC, CG8M, or CF3M(2) | NPS 1, 1-1/2, 2 | CL150/300/600 flangeless | |

| NPS 3, 4 | CL150 and CL300/600 flangeless | |||

| NPS 6, 8 | CL150/300 and CL600 flangeless | |||

| NPS 10 | CL150 flangeless | |||

| WCC, LCC, or CG8M | NPS 2, 3, 4, 6, 8 | CL600 | ||

| CW2M, M35-2, or CK3MCuN | NPS 1, 1-1/2, 2, 3, 4, 6, 8 | CL150/300/600 flangeless | ||

| CK3MCuN | NPS 10 | CL150 flangeless | ||

1. WCC and EN Stl 1.0619 are dual certified. CF3M and EN SST 1.4409 are dual certified. 2. CF3M is a standard offering in Europe and Asia Pacific. 3. NORSOK compliant materials available upon request. 4. Flangeless V200 assemblies mate with raised-face flanges. 5. Valve body mates with NPS 24 ASME CL150 flanges. Internal based on NPS 20 valve design

Fisher Vee-Ball V200 Segmented Ball Valve – Rotary Valves – Construction

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.