SICK LBV300 Level Sensors – ATEX Hazardous Area

SICK SENSORS

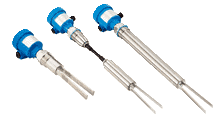

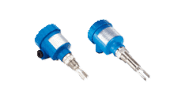

SICK LBV300 Level Sensors

- Tough device design

- Several housing materials and electrical outputs available

- Immune to deposit formation

- Commissioning without filling

- Process temperature up to 250 °C

- Very high repeatability

- ATEX versions (1D/2D/1G/2G) available

- Tube-extended version (LBV330) up to 6 m and rope extensions version (LBV320) up to 80 m available for vertical mounting

SICK LBV300 Level Sensors – BENEFITS

- Easy installation and commissioning, no calibration necessary

- Easy operation and integration, saves time

- Maintenance-free sensor, reduces downtime

- Testing in place possible – no mounting required, which reduces installation time

- Flexible and tough system for a multitude of applications

- Solutions for vertically mounted switches in difficult installation conditions and surroundings

SICK LBV300 are rugged, reliable, and highly accurate vibrating level switches and signal full, empty, or demand states in bulk materials. The tuning fork reacts to changes in density, and thus operates independently of silo shape or the tank material used.

The rugged stainless steel tuning fork is piezo-electrically energized and vibrates at its resonance frequency when it is covered by bulk materials. This change is detected and converted into a switching signal.

While the SICK LBV310 compact device is used for horizontal mounting and to signal full states, the LBV320 cable-extended switch and the LBV330 tube-extended switch are used for vertical mounting in silos and bridge sensing ranges of up to 80 m and 6 m respectively.

With a wide variety of thread and flange connections, and several electronic variants, the SICK LBV330 offers a solution for almost all applications, even in potentially explosive atmospheres.

ATEX Hazardous Area Level Sensors – SICK

SICK Level Sensors – Continuous Level Measurement & Point Level Measurement

SICK LBV301 Level Sensors – ATEX Hazardous Area – TECHNICAL DATA

| Measurement principle: | Vibrating level switch |

| Detection principle: | Contact |

| Medium: | Bulk solids |

| Measurement: | Switch |

| Process temperature: | –50 °C … +250 °C |

| Process pressure: | –1 bar … 25 bar |

| Output signal: | Non-contact switch, Double relay (DPDT) 1 x PNP/NPN, NAMUR signal |

| Accuracy of sensor element: | ± 10 mm |

Bulk solid LEVEL SENSOR APPLICATIONS

SICK LBV300 Level Sensors enables level measurement and point level measurement of solids.

Level measurement in the material container

The UP56 ultrasonic level sensor continuously measures how full the material container is.

Alternatively, in the case of large silos, the LBV3x0 vibrating level sensors can detect the minimum and maximum fill levels in the material container.

➡ Did you know? T&D Hazardous Area team are trained and certified in the specification and sale of flameproof and explosion-proof equipment, including Crowcon Gas Detectors.