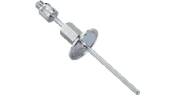

SICK TCT Temperature Measurement Sensors

SICK SENSORS

SICK TCT Temperature Measurement Sensors

- Pt100 element, accuracy class A according to IEC 60751

- Measuring ranges –50 °C … +150 °C and –50 °C … +250 °C

- Wetted parts made from corrosion resistant stainless steel 1.4571

- Various mechanical adaptations and insertion lengths, also available with thermowell

- Pt100 (4-wire) or 4 mA … 20 mA (2-wire)

- Circular connector M12 x 1 (IP 67) or L-connector according to DIN EN 175301-803 A (IP 65)

SICK TCT – BENEFITS

- Reliable operation through rugged design and high-quality materials

- Very good long-term stability, accuracy and linearity

- Quick and safe installation

- Convenient system integration even in narrow installation spaces

- Optimal solutions for individual requirements due to versatile configurability

SICK TCT Temperature Measurement Sensors are universal Pt100 resistance thermometers with a compact stainless steel housing for temperature measurement in liquids and gases. The Pt100 is positioned inside the tip of the probe and it is possible for the temperature measurement sensor to come with a protective pipe.

The SICK TCT is available with a variety or process connections, insertion lengths and can come with or without compression fittings that can be adaptable with a range of applications. Wetted parts of the SICK TCT are made from high-grade stainless steel 1.4571. Besides its Pt100 output signal, the TCT is available with an integrated transmitter with output signal 4 mA … 20 mA.

| Measuring range | –50 °C +150 °C –50 °C +250 °C |

| Accuracy of sensor element | Class A according to IEC 60751 |

| Accuracy of the opt. measuring transducer | ≤ ± 0.1 % of span |

| Signal outputs and maximum ohmic load RA | Pt100, 4-wire, 4 mA … 20 mA, 2-wire (RA ≤ (L+ – 9 V) / 0.023 A [Ohm]) |

| Electrical connection | Round connector M12 x 1, 4-pin, IP 67, L-connector (DIN EN 175301-803 A), 4 pin, IP 65 |

Temperature Measurement SENSOR APPLICATIONS

SICK TBT Temperature Measurement Sensors enable temperature measurement of liquids and gases in industrial applications.

- Monitoring of cooling water temperatures

- Monitoring of hydraulic oil temperatures

- Tank and tote construction

- Machine and plant engineering

- Heating systems

Temperature measurement in the steam line

In a block molding machine the polystyrene beads plasticize and increase in size when hot steam is supplied to the machine.

The temperature of the hot steam in the supply line to the mold machine is measured by the TCT temperature sensor.

➡ Did you know? T&D Hazardous Area team are trained and certified in the specification and sale of flameproof and explosion-proof equipment, including Crowcon Gas Detectors.