ASCO™ 327C Solenoid Valves | (Direct Acting) 3/2, High Flow, ¼” Porting, 316 Stainless Steel Balanced Poppet Type

ASCO 327C Solenoid Valves | 3/2 Direct Acting Solenoid Valve

Thorne & Derrick | Distributed from Stock | UK & Export Sales | Customer Service Excellence | ATEX Compliant Solutions

ASCO™ 327C Solenoid Valves

ATEX Solenoid Valves | Series 327C

ASCO 327C solenoid valves are recognised for their efficiency and reliability in various applications. Being 3/2 way direct-operated pilot valves, they offer a straightforward solution for controlling the flow of fluids in pneumatic and hydraulic systems.

The ASCO Series 327C solenoid valves are designed for optimal performance in various demanding applications. With advancements in technology, these valves provide enhanced reliability and responsiveness, making them suitable for a wide range of industrial uses including in hazardous areas.

ASCO™ Series 327C Solenoid Valves

Features

- High Flow Piloting with no minimum operating pressure required

- Balanced Poppet construction for high flow at minimum power levels

- PTFE rider rings and graphite-filled seals reduce friction and eliminate sticking to provide exceptional service life

- 316L Stainless Steel construction for highly corrosive atmospheres

- NAMUR mount option available

- Product is SIL (Safety Integrity Level) 3 Capable to IEC 61508-1 Exida certified

- Optional CRN (Canadian Registration Number) and other regional certificates available

VIDEO: The Next Generation of High Flow Solenoid Valves ASCO 327C

This video highlights the direct-acting, high-flow design of the new ASCO Series 327c solenoid valve and how that delivers superior flow control performance and operational certainty for power plants, refineries and chemical processing facilities.

Industry leading performance, simple to install and maintain

- Increase operational efficiency – best-in-class power to flow ratio enhances process valve actuation efficiency

- Low power requirements – design optimized to minimize friction, reducing power consumption and removing need for additional power supplies

- Greater operational certainty – designed to operate reliably in the most extreme conditions

- Enhanced reliability – molded pin terminal design enhances water ingress protection and low power design eliminates heat degradation

- Simplified installation – external terminals to expedite testing and minimize field commissioning time

- Reduce supply chain complexity – global and regional certification enables part standardisation

ASCO™ High Flow Direct Acting Valves

Series 327C

| Performance Data | |

| Construction | Standard Construction |

| Enclosures | Epoxy powder coated Aluminium or 316L Stainless Steel |

| Flow, Kv (Cv) | 0.7 (0.8) |

| Maximum Operating Pressure Differential, bar (psi) |

12 (174) |

| Fluid Media | Air, Inert Gas, Water, Light oil |

| Maximum Viscosity mm2 /s cST | 65 |

| Ambient and Fluid Temperature, Standard FKM Seals, °C (°F) | UL, C/US: -20 to 84 (-4 to 183) ATEX: -20 to 90 (-4 to 194) |

| Ambient and Fluid Temperature, Low-Temperature FVQM Seals, °C (°F) | -60 to 60 (-76 to 140) |

| Construction | |

| Body | 316L Stainless Steel |

| Core Tube | 316L Stainless Steel |

| Stem & Insert | 316L Stainless Steel |

| Core & Plugnut | 430F Stainless Steel |

| O-ring Holder | 316L Stainless Steel |

| Springs | 17-7 Stainless Steel |

| Seals & Discs | FKM (standard) or FVMQ (low-temperature construction) |

| Rider Ring | PTFE Graphite filled |

| Temporary Connector | Plastic (UDEL P-1700 BK 937) |

| Electrical | |

| Voltage | DC: 6, 12, 24, 48, 120, 240 Class H 125, 250 DC Battery Charging AC: 24/50-60, 48/50-60 Class H 120/60,110/50 Class H 208/50-60 Class H 240/60, 230/50 Class H |

| Power, Watts | AC: 2.7 DC: 1.9 ≤24v, >24v 2.6 to 3.6 |

| Enclosure Approvals | |

| Ingress Protection | IP 66 & 68 Type 4X & 6P |

| Hazardous Location | UL, Ulc CLI, Div 1, Gp B, C, D and CLII, Div 1 Gp E, F, G ATEX/IECEx: ll 2 G Ex db llC T5/T6 Gb ll 2 D Ex tb lllC T85°C/ T100°C Db |

327C Solenoid Valves

Recommended Codes

| Suggested Codes * | Construction | Body (SS) | Electrical Connection (*Equivalent Temporary Connector Code) | Options | Voltage | Power | Dimensions |

| 8327C102F392LH9 | Standard | Threaded | 1/2” NPT, SS, Surge Suppression|*TK | MO/MS | 48/DC | 2.6W | A |

| 8327C102F39YTHN | None | 125 DC Battery charging | 2.7W | ||||

| 8327C102FN9YTH0 | 1/2” NPT, Al | *TA | 120/60, 110/50 | 2.7W | ||||

| 8327C112FS9YTH0 | Low Temp | 1/2” NPT, SS | *TB | 120/60, 110/50 | 2.7W | |||

| 8327C302F392JH1 | Standard | 1/2” NPT, SS, Surge Suppression | *TK | MO | 24/DC | <2W | ||

| 8327C302F392KH1 | MS | |||||

| 8327C302F39YTH1 | None | |||||

| 8327C302F49YTH1 | 20mm, SS, Surge Suppression | *TM | |||||

| 8327C302F89YTH1 | 1/2” NPT, Al, Surge Suppression|*TJ | |||||

| 8327C302F29YTH1 | 20mm, Al, Surge Suppression | *TL | |||||

| 8327C312F89YTH1 | Low Temp | 1/2” NPT, Al, Surge Suppression|*TJ | ||||

| 8327C312F29YTH1 | 20mm, Al, Surge Suppression | *TL | |||||

| 8327C305F292JH1 | Standard | Namur | 20mm, Al, Surge Suppression|*TL | MO | B | |

| 8327C305F39YTH1 | 1/2” NPT, SS, Surge Suppression|*TK | None | ||||

| 8327C305F892JH1 | 1/2” NPT, Al, Surge Suppression|*TJ | MO |

* For alternative threads replace prefix 8 with G or J

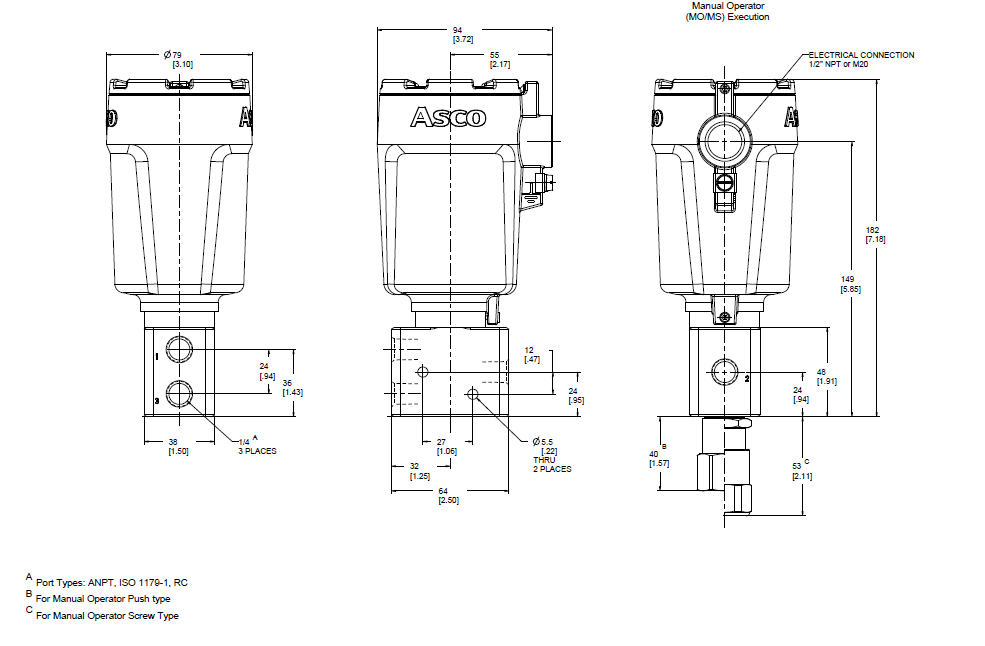

Dimensions A: mm (inches) Threaded

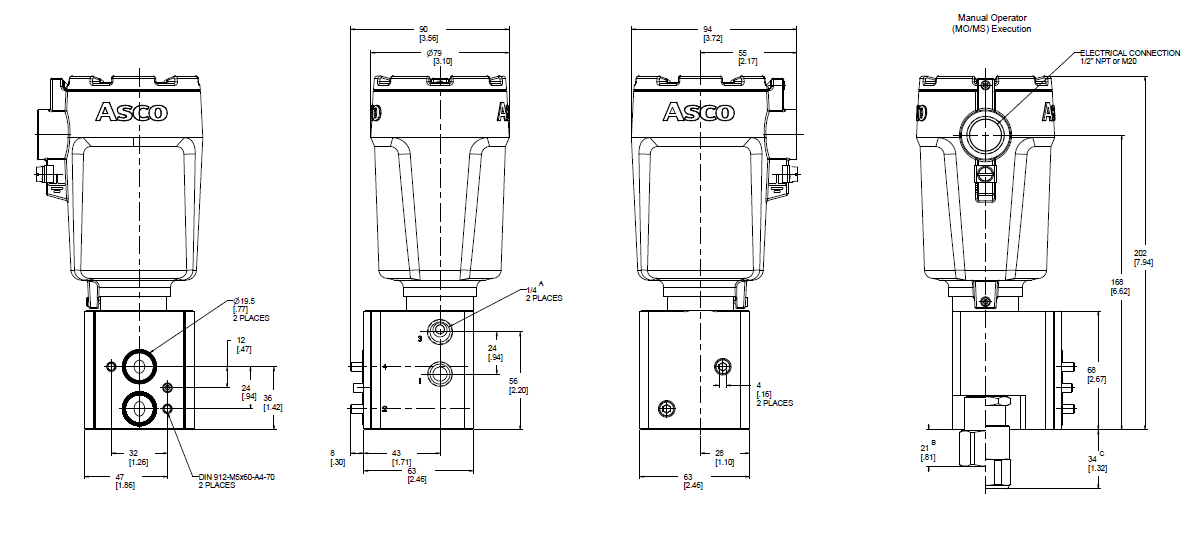

Dimensions B: mm (inches) Namur

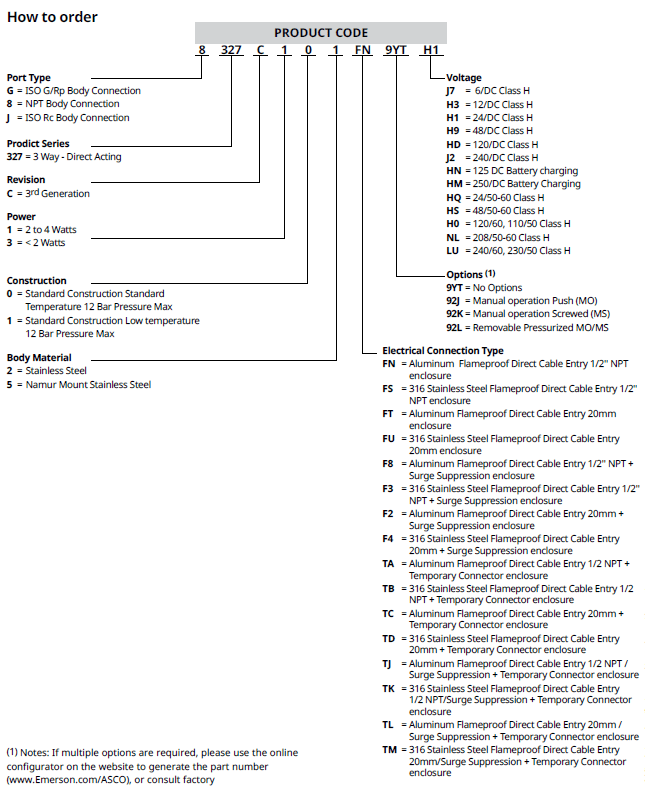

How To Order ASCO Valves