Fisher A31A Butterfly Valve – Rotary Valves

Fisher A31A Valve Butterfly Valve – Rotary Valves

Fisher A31A Valve is a high performance butterfly valve with a single flange or flangeles wafer-style design body featuring a keyed shaft for on/off service.

A keyed drive shaft combines with a variety of handlevers, handwheels, or pneumatic piston diaphragm actuators to make the Fisher A31A valve a reliable, high-performance butterfly valve for a variety of on-off applications in the various process industries.

The A31A valve can be supplied with one of several dynamic seals that can be used in a variety of demanding applications

Fisher A31A is available in NPS 14 through 24, CL 150 and CL 300 and is suitable for most industry applications thanks to having a wafer or lugged body with a variety of seals. The Cryogenic version of this valve is available in NPS 3 through 24.

Fisher A31A Valve Butterfly Valve – Product Features

- Economical Tight Shutoff – the pressure-assisted seal design provides tight shutoff and permits the use of smaller, less expensive actuators in applications requiring full ASME B16.34 shutoff capabilities

- Excellent Shutoff Integrity – concentric rotation helps to ensure that the valve disc remains in the closed position in spite of line pressure surges or actuator failure

- True Bi-directional Shutoff Performance – valve design helps to ensure that the torque necessary to open and close the valve is the same regardless of the direction in which the differential pressure is applied

- Safety – shaft blowout protection is designed into the A31A valve. The anti-blowout gland fits securely over the valve shaft which has been turned down to form a circumferential shoulder that contacts the anti-blowout gland

- Ease of Maintenance– interchangeability of all parts including shafts and discs simplifies service and reduces maintenance costs

- Improved Environmental Capabilities – the ENVIRO-SEAL packing system can control emissions below the EPA (Environmental Protection Agency) limit of 100 ppm (parts per million) for valves

- Easy Installation – the valve body self-centers on the line flange bolts as a fast, accurate means of centering the valve in the pipeline

- Reliable Flange Gasketing Surface – seal retainer screws are located so there is no interference with the sealing function of either flat sheet or spiral wound line flange gaskets

FISHER A31A VALVE BUTTERFLY VALVE

PRODUCT Specification

| Available Valve Configurations | Flangeless (wafer) style or single-flange (lugged) control valve with a one-piece valve body, a two-component seal/backup O-ring, and a keyed drive shaft |

| Valve Body Sizes | NPS 14, 16, 18, 20, and 24 |

| End Connection Style | Flangeless style or single flange valve body designed to fit between raised-face mating flanges per ASME B16.5 CL150 or CL300 |

| Valve Body Classification | Face-to-face dimensions are in compliance with MSS SP68 and API 609 standards; valve bodies are designed for installation between ASME B16.5 CL150 or CL300 raised-face flange |

| Maximum Inlet Pressure/Temperature | Consistent with CL150 and CL300 pressure/temperature ratings per ASME B16.34. A |

| Disk Coating | Hardcoating |

| Shaft Extension Lengths | None required for temperatures less than 343C (650F), 152.4 mm (6 inches) for temperatures from 343 to 538C (650 to 1000F), or 304.8 mm (12 inches) for temperatures above 538C (1000F) Shu |

| Shutoff Classification per ANSI/FCI 70-2 and IEC 60534-4 | Standard Soft Seal: Bidirectional bubble-tight shutoff NOVEX Seal: Unidirectional shutoff MSS-SP61 (preferred flow direction only(3)), optional Class VI Phoenix III Seal: Bidirectional bubble-tight Phoenix III Seal for Fire Tested Applications: Shutoff per FCI 70-2 Class VI. Fire Tested per API 607 |

| Available Actuators | Handlever, handwheel, or pneumatic piston |

| Disk Rotation | Clockwise (CW) to close |

1. The valve sizes listed in this bulletin refer to Nominal Pipe Size (NPS). 2. The pressure/temperature limits in this bulletin (figure 2), and any application code or standard limitation, should not be exceeded. 3. For optimum seal performance, the preferred valve orientation at shutoff is with the retaining ring downstream from the high pressure side of the valve.

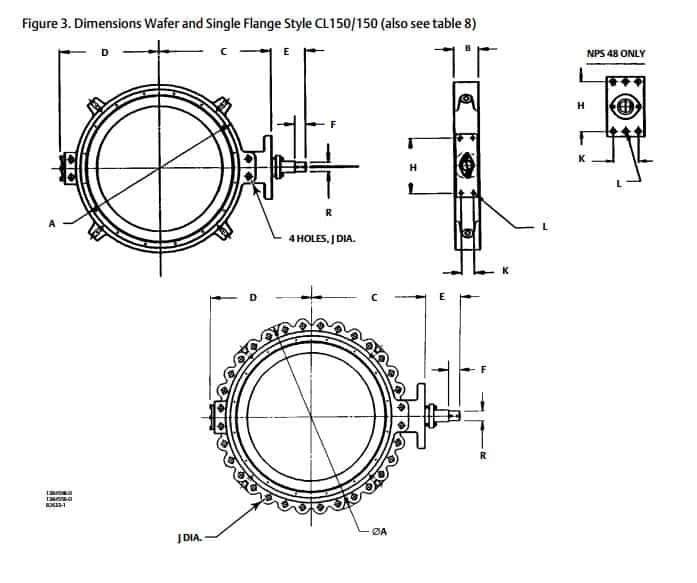

FISHER A31A VALVE BUTTERFLY VALVE Dimensions & Weights (Wafer style, CL150)

| Valve Size NPS | A(1) | D | E | G | K | M(2) Min. I.D. | R | S (Shaft Dia at Keyway) | Key SQ Size | T | U | W | Y | Approximate Weight |

| mm | kg | |||||||||||||

| NPS 14 | 91.9 | 146 | 63.5 | 295 | 327 | 331 | 422 | 30.2 | 6.35 | 235 | 46.0 | 17.5 | – | 72 |

| NPS 16 | 102 | 146 | 63.5 | 318 | 371 | 375 | 470 | 31.8 | 6.35 | 235 | 46.0 | 17.5 | 28.4 | 94 |

| NPS 18 | 114 | 229 | 79.5 | 349 | 400 | 419 | 533 | 38.1 | 9.35 | 273 | 50.8 | 20.6 | 31.8 | 139 |

| NPS 20 | 127 | 229 | 79.5 | 381 | 432 | 464 | 584 | 44.5 | 9.53 | 273 | 50.8 | 20.6 | 31.8 | 167 |

| NPS 24 | 154 | 154 | 104..9 | 438 | 492 | 581 | 692 | 57.2 | 12.7 | 337 | 76.2 | 23.9 | 35.1 | 255 |

Fisher A31A Valve Butterfly Valve Dimension & Weights (Wafer Style, CL150)

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Installing Fisher A31A Butterfly Valve

Fisher A31A butterfly valves should be installed with the shaft upstream of the seal (retaining ring downstream from the high pressure side of the valve). The standard soft seal offers bubble-tight, bidirectional shutoff.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.