ATEX Inspect | Engineering Solutions For A Compliant Future

Published 11 Dec 2020

Inspection Software for a Compliant Future | Safer Working & Management of Equipment in Explosive Atmospheres & Hazardous Area Workplaces

What is ATEX Inspect?

ATEXInspect is a cloud based software for the management of equipment installed in hazardous area locations and potentially explosive atmospheres (ATEX).

The ATEXInspect app can be used on any device with a browser and internet connection.

There is no need to install any software, just login and access your secure data from anywhere you need.

It will carry out inspections and automatically raise faults straight from your inspection. These faults can then easily have work orders assigned to them, completing the cycle.

Use ATEXInspect to manage other inspections such as emergency ATEX lighting and fixed wire inspections.

ATEXInspect can easily be used with tablets designed for hazardous areas.

Allowing all related documents, drawings and certification to be accessed from one device while on site or in the office. The software can be accessed from multiple locations allowing collaboration between your sites and offices.

Why ATEX Inspect?

- Team Collaboration – ATEXInspect allows remote collaboration. The originator may be on one site (or continent) and the checker or approver on another.

- Element & Tag Database – The element database and Tag management application work together to manage your assets and allow you to reuse your elements throughout ATEXInspect.

- Competence is now Mandatory – ATEX Inspect only allows personnel with appropriate competence levels to check and/or approve records.

- Automatic QA Version Control – All critical records are traceable to originator/checker/approver with automatic ‘revving’.

- Location Management – Manage your records using a hierarchy. Site – Plant – Area.

ATEX Inspect Features

Fault Management System

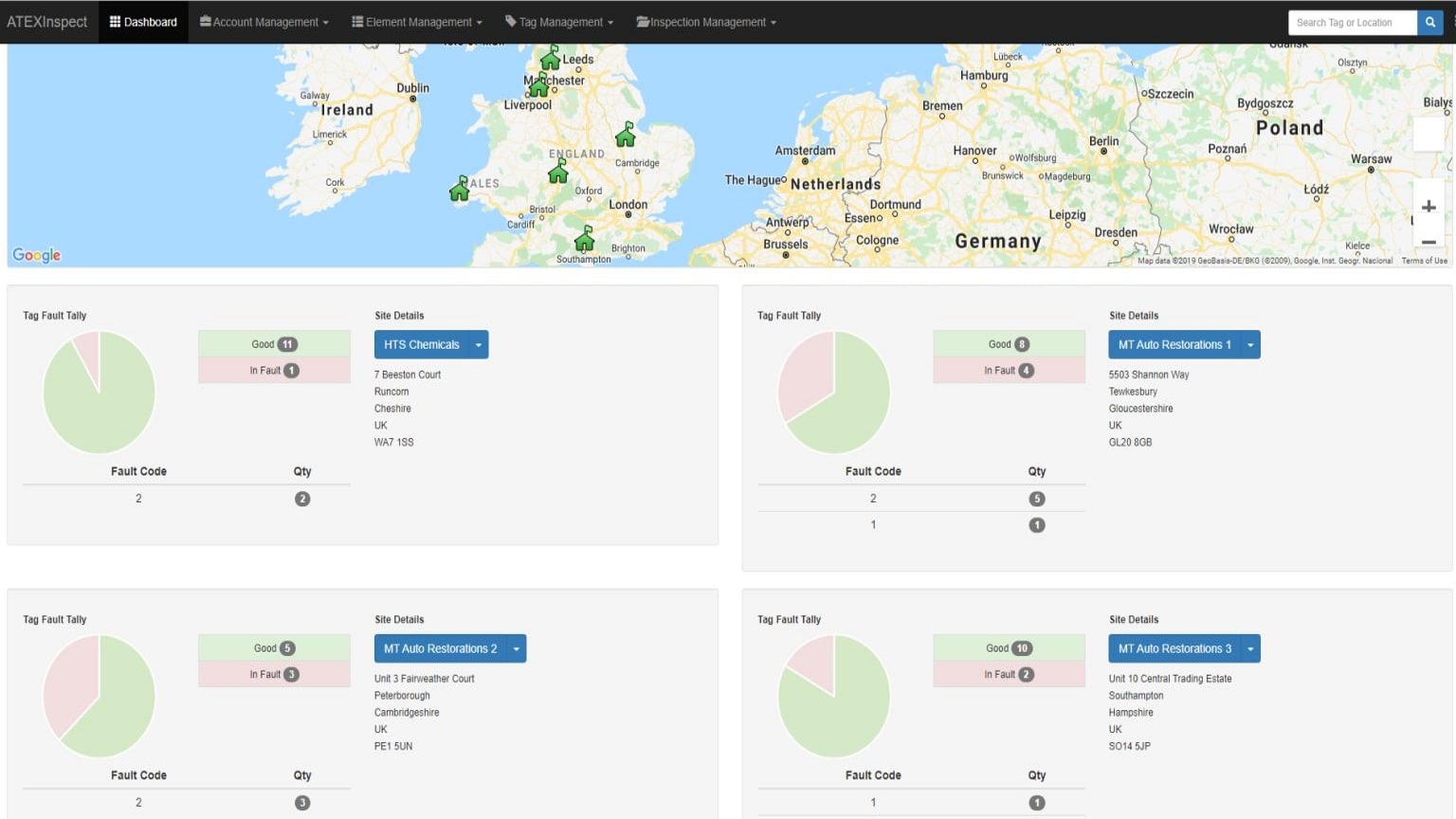

ATEXInspect has an innovative fault management system that gives live and updated information in real time. It enables the user to create your site standard fault codes, that can be assigned when hazardous area equipment is inspected.

Using the ATEXInspect dashboard you can quickly identify how many of your tags are in fault, which are then categorised into the resolution of a fault, your operator can easily access the related tag and close out the fault.

Site manager reviewing inspections and faults from the office

Reporting In Hazardous Area & Explosive Atmospheres

Included in ATEXInspect, the sophisticated reporting system allows the user to produce comprehensive reports based on your inspections.

These reports can be exported at site level or can be filtered down to a specific tag. They are available in both PDF or Excel formats, to support the needs of individual businesses.

Report Types

- Site fault reports

- Plant fault reports

- Area fault reports

- Inspection reports

- Emergency lighting reports

- Fixed wire reports

Data available immediately and accessible using any device with an internet connection

Hazardous Area Inspections

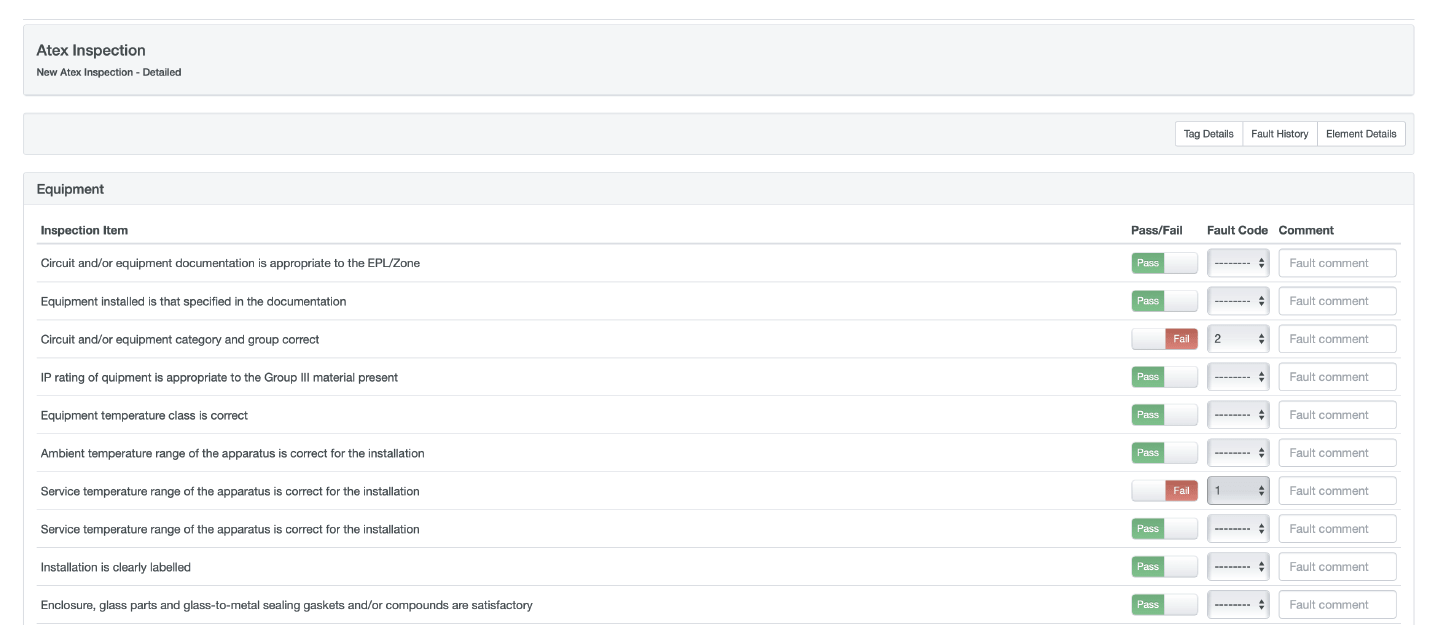

ATEXInspect offers three different types of inspections: ATEX Inspection, Fixed Wire Inspections & Emergency Lighting Inspections. All three are integrated into our fault management system. ATEX Inspect makes ATEX inspection effortless, by conveniently providing all information required to carry out inspections.

Who can inspect assets in a Hazardous Area?

IEC 60079-17:2013 states that inspectors must be able to demonstrate competency. ATEXInspect is a partner of HTS Group who have competent engineers with experience providing ATEX inspection services for a wide range of clients within the UK.

How can you prove the competency of staff performing inspections on your assets?

Certifications such as CompEx that prove competency can be uploaded to each user’s profile, each user has permissions that can be controlled via the competency register. Only competent staff have permission to check and approve records.

How is data on ATEXInspect secured?

Any data uploaded to ATEXInspect is stored using secure cloud servers. This allows data to be managed in alignment with security best practices and meet a variety of IT security standards. All communications between the user and the server are carried out over an encrypted connection (HTTPS). The data is backed up using a snapshot system allowing data to be recovered from previous dates.

Cloud based software for the management of equipment installed in potentially explosive atmospheres (ATEX). It will carry out inspections and automatically raise faults straight from your inspection. These faults can then easily have work orders assigned to them, completing the cycle | Contact us

Thorne & Derrick are leaders in ATEX & IECEx Product Innovation providing Lighting, Heating, Ventilation and Security in Explosive Atmospheres.

Talk to us today about how we can improve operational safety, energy efficiency and optimise productivity in your hazardous areas.

We are your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for your UK and international projects.

>>> GO TO INNOVATION <<<

EXPERTS IN EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Since 1985, T&D have established a solid reputation based on Service, Integrity and Trust.

From our distribution locations with 50,000+ sq feet warehouse capacity and a £2.5 million stock, we can supply many products by next day delivery – our key sectors are the process, pharmaceutical, chemical, utility, food/beverage, renewable and oil/gas industries.