Fisher 8560 Butterfly Valve – Rotary Valves

Fisher 8560 Butterfly Valve – Rotary Valves

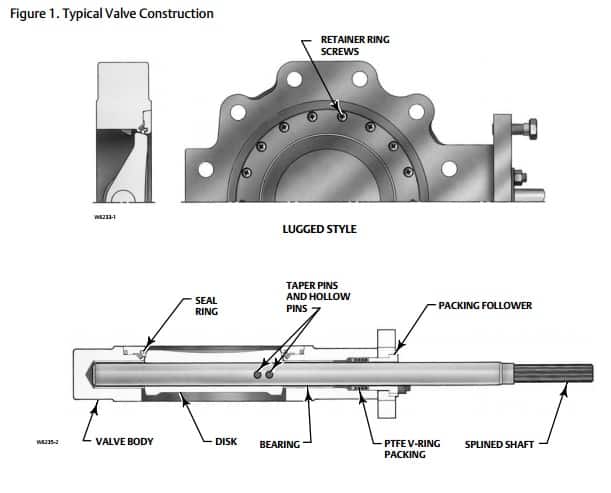

Fisher 8560 Valve is a high performance butterfly valve with a splined shaft suitable for throttling control featuring a stainless steel disk with a stainless steel seal ring. The pressure-assisted metal seal ring provides excellent shutoff against pressure applied in the recommended flow direction for both liquid and gas applications.

Fisher 8560 is available in NPS 2 through 12, CL150 and CL30 and is suitable for most industry applications thanks to having a flangeless (wafer) or single flange body and wide variety of seals.

The NPS 2 valve is multi-rated to CL150/300/600.

Fisher 8560 Valve Butterfly Valve – Product Features

- Economical Tight Shutoff – bidirectional soft seal ring with pressure assisting action results in exceptional shutoff per Class VI

- Excellent Flow Control – the eccentrically- mounted disc design provides an approximate linear flow characteristic and can be used for throttling or on/off control applications through 90 degrees of disc rotation

- Sour Service Capability – trim and bolting materials are available for applications involving sour service. These constructions comply with the recommendations of NACE MR0175-2002

- Improved Environmental Capabilities – the optional ENVIRO-SEAL packing system is designed with improved sealing, guiding, and loading force transmission. The ENVIRO-SEAL packing system can control emissions to below the EPA (Environmental Protection Agency) limit of 100 ppm (parts per million) for valves

- Integral Shaft-to-Body Bonding – Standard valve construction includes conductive packing to provide electrical bonding for hazardous area applications

- Low Cost Maintenance – the ENVIRO-SEAL packing system can control emissions below the EPA (Environmental Protection Agency) limit of 100 ppm (parts per million)

- Easy Installation – individual disc/shaft components can be replaced after disassembly due to sleeve and taper pin connections

- Reliable Flange Gasketing Surface – seal retainer screws are located so there is no interference with the sealing function of either flat sheet or spiral wound line flange gaskets

FISHER 8560 VALVE BUTTERFLY VALVE

PRODUCT Specification

| Valve Sizes and End Connection Styles | NPS 3, 4, 6, 8, 10, and 12 valve size available in lugged style Maxi |

| Maximum Inlet Pressure(1) | Carbon Steel and Stainless Steel Valve Bodies: Consistent with CL150 and 300 pressure-temperature ratings per ASME B16.34 unless limited by material temperature capabilities |

| Maximum Pressure Drops(1) | VConsistent with CL150 and 300 pressure-temperature ratings per ASME B16.34 except for Phoenix III seals which are derated at some higher pressure-temperature values |

| Shutoff Classifications | NOVEX Seal: For NPS 3 through 12. Unidirectional shutoff is Class IV. See figure 2 Phoenix III Seal: For NPS 3 through 12. Bidirectional shutoff to Class VI per ANSI/FCI 70-2 and IEC 60534-4. See figure 2. For the optional Phoenix III Fire-Tested seal(2) |

| Material Temperature Capabilities(1) | NOVEX Seal: -46 to 538C (-50 to 1000F) Phoenix III: -46 to 232C (-50 to 450F) Fl |

| Disk Rotation | Clockwise to close (when viewing from the drive shaft end) through 90 degrees of disk rotation |

| Actuator/ Valve Action | With a diaphragm or piston rotary actuator, the valve action is field-reversible. |

| Valve Classification | Face-to-face dimensions of NPS 3 through 12 valves in CL150 or 300, meets API 609 or MSS-SP68 standards for face-to-face dimensions of lugged valves |

| Mating Flange Capabilities | All sizes compatible with CL150 and 300 flanges |

| ENVIRO-SEAL Packing | This optional PTFE or graphite packing system provides improved sealing, guiding, and transmission of loading force to control liquid and gas emissions |

1. The pressure-temperature limits in this bulletin and any applicable standard or code limitation should not be exceeded. 2. For component selection and applicable fire-tested standards and codes, consult your Emerson Process Management sales office (see table 2). 3. Ratio of maximum flow coefficient to minimum usable flow coefficient.

| Valve Size NPS | Cv FORWARD FLOW WITH DISK WIDE OPEN (90 DEGREES ROTATION) | |

| CL150 | CL300 | |

| 3 | 237 | 237 |

| 4 | 499 | 488 |

| 6 | 1250 | 1110 |

| 8 | 2180 | 2070 |

| 10 | 3600 | 3480 |

| 12 | 5400 | 5130 |

- measured in gallons per minutes at 1 psi differential pressure across the butterfly valve

- NPS is Nominal Pipe Size

Fisher 8560 Butterfly Valve – Valve Construction

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Installing Fisher 8560 Butterfly Valve

Fisher 8560 butterfly valves should be installed with the shaft horizontal in a normal flow direction – horizontal installation will enhance valve performance as process fluids will sweep entrained solids from valve surfaces preventing particle build-up on the valve seals.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.