Increased Safety Plugs Ex de Hazardous Area Plugs 16Amp & 32Amp | ATX PRE

Zone 1 Zone 2 Plugs ATEX | Ex de Hazardous Area Plugs 16Amp | ATX PRE

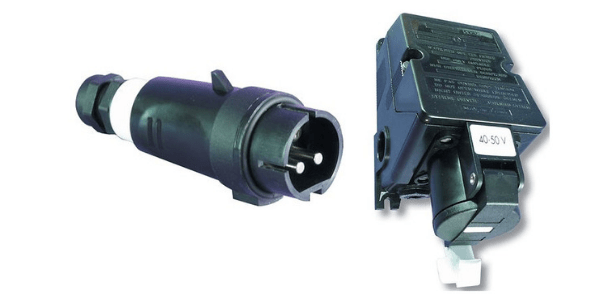

Increased Safety Plugs

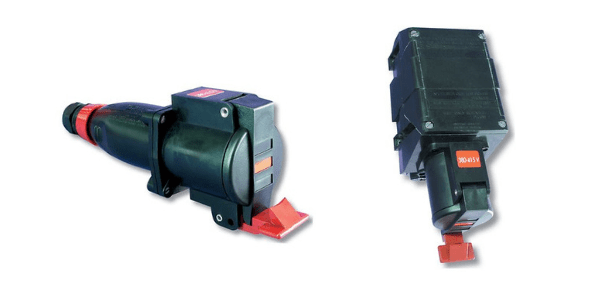

Appleton ATX PRe Series 16 & 32 Amp Plugs & Sockets

Plugs & Sockets | ATEX Certified | Zone 1 & Zone 2 Hazardous Areas

PRE Series 16 & 32 Amp Plugs and Sockets manufactured by Appleton ATX use a pin and sleeve design to deliver safe power to stationary and portable equipment in hazardous areas and those classed as Zone 1 and 2 and Zone 21 and 22. Suitable for use in damp, wet or corrosive environments, PRE plugs and sockets are keyed and color coded per IEC directives. The sockets are available in wall-mount, flush-mount and mobile versions.

♦ See our complete range of ATEX Plugs for hazardous area electrical power distribution at low voltage – this includes flameproof plugs according to the Ex d Explosion Protection concept.

Typical Hazardous Area Applications

- Lighting Systems

- Conveyors

- Heaters

- Motor Generators

- Air Conditioning Equipment

- Compressors

The Appleton ATX PRE Series plug and socket system, certified and approved according to ATEX, is designed with a safe disconnect mechanism to insure maximum hazardous location and workplace protection.

PRE plugs feature contact separation in a flameproof chamber with the automatic electrical disconnection of each phase contained in a second flameproof chamber.

The same plug used in hazardous locations, including Zone 1 and Zone 2, can also be safely used with interlocking non-hazardous IEC 309 sockets. Different voltages are color coded for easy identification.

Plugs & Sockets

Specifications

- Hazardous Area Classification: Zone 1 and 2 – 21 and 22; Ex II 2 GD; IP66; IK09/10

- Operating Temperature: -40 °C to +55 °C (-40 °F to +131 °F)

- Voltage: 20/25 Vac, 20/50 Vac, 40/50 Vac, 100/130 Vac, 200/250 Vac, 380/415 Vac, 480/500 Vac or 50/500 Vac

- Number of Poles: 2, 3

- Number of Wires: 3, 4, 5

- Hertz: 50/60 or 300 to 500 Hz

- Materials and Finishes: Wall Socket for 2P – 2P+E – 3P is high impact resistance polycarbonate. Wall Socket for 3P+E – 3P+N+E: high impact resistance fiberglass reinforced polyester. Polyamide plug, mobile socket and flush socket.

- ATEX Certified

➡ The following table enables the correct selection and specification of the suitable plug and socket assembly to provide safe distribution of LV power in hazardous area locations; including Zone 1 & Zone 2 explosive atmospheres.

Ex de Plugs & Sockets Selection

Increased Safety

| Ex de – 1 Cable Gland Supplied | Appleton ATX Order Code – SOCKET | Appleton ATX Order Code – PLUG |

| 2P+E – 16A Plug – 200/250 V – 50/60 Hz | PRE316RB | PRE316PB |

| 2P+E – 16A Plug – 200/250 V – 50/60 Hz | PRE316MB (Mobile Socket) | PRE316PB |

| 3P+E – 16A Plug – 380/415 V – 50/60 Hz | PRE416RR | PRE416PR |

| 3P+E – 32A Plug – 380/415 V – 50/60 Hz | PRE432RR | PRE432PR |

ATEX IECEx Certifications and Compliances

Certification Type PRE

Appleton ATX PRE Series 32 Amp Plugs and Sockets

- Gas: Zones 1 and 2

- Conforming to ATEX 94/9/CE: Ex II 2 G

- Type of Protection: Ex de IIC

- Temperature Class: T6 for Ta ≤ +40 °C (-40 °F) and T5 for +55 °C (+131 °F)

- Dust: Zones 21 and 22

- Conforming to ATEX 94/9/CE: Ex II 2 D

- Type of Protection: Ex tD A21

- Surface Temperature: T68 °C (T154 °F)

- Impact Resistance (shock): IK10 (Polyester) and IK09 (Polyamide)

- CE Declaration of Conformity: 50228

- ATEX Certificate: LCIE 02 ATEX 6068

- IECEx Certificate: IECEx LCI 04.0014

Lighting | Control Stations | Plugs & Sockets | Junction Boxes | Hazardous Area ATEX Certified Electrical Equipment for Explosive Atmospheres | Zone 1 & Zone 2