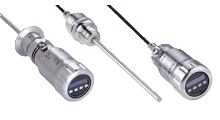

SICK LFP Inox Level Sensors

SICK SENSORS

SICK LFP Inox Level Sensors

- Level measurement in hygienic applications

- Manually retractable monoprobe up to 4,000 mm long with Ra ≤ 0.8 µm

- Process temperature up to 180 °C, process pressure up to 16 bar

- CIP/SIP-resistant

- High enclosure rating: IP67 and IP69K, autoclavable

- Interchangeable hygienic process connections

- 3-in-1: combined display, analog output, and binary output

- Remote amplifier with process connection

SICK LFP INOX – BENEFITS

- Robust design increases service life of the level sensor

- High flexibility due to cutable probe and interchangeable connection concept

- Cost savings due to multiple output signals: one system for both level detection and continuous level monitoring

- Time and cost savings due to low maintenance without any calibration and quick commissioning

- Remote display of the measured value and space savings

SICK LFP Inox Level Sensors are hygienic level sensors for liquids using TDR technology – a process for determining the time of flight of electromagnetic waves. The time difference between the sent pulse and the reflected pulse is used to generate a level signal, both as a continuous value (analog output) and a freely positionable switching point (switching output).

The use of FDA-compliant materials in an EHEDG-certified design means that the LFP Inox can be relied upon for optimum and unrestricted cleaning, even in applications with the most stringent hygiene requirements.

SICK LFP modular connection system allows simple and flexible installation in any application – with high temperature and pressure resistance, unrestricted use is possible under CIP and SIP conditions. Communication capability via IO-Link to the superordinate control units.

SICK Level Sensors – Continuous Level Measurement & Point Level Measurement

SICK LFP INOX – TECHNICAL DATA

| Measurement principle: | TDR sensor |

| Detection principle: | Contact |

| Medium: | Fluids |

| Measurement: | Switch, Continuous |

| Process temperature: | –20 °C … +180 °C |

| Process pressure: | –1 bar … 16 bar |

| Output signal: | 1 x PNP + 1 x PNP/NPN + 4 mA … 20 mA / 0 V … 10 V / 1 x PNP + 3 x PNP/NPN + 4 mA … 20 mA / 0 V … 10 V |

| Accuracy of sensor element: | ± 5 mm |

LIQUID LEVEL SENSOR APPLICATIONS

SICK LFP Inox Level Sensors enables both continuous level measurement and point level measurement of liquids in metal containers, tanks and vessels – this includes liquids that foam or film.

- detecting the level in filling machine buffer tanks in milk production

- monitoring the level in CIP and SIP systems in the pharmaceutical industry

- monitoring fill level of water and chemicals in cleaning systems in mechanical engineering

- monitoring lubricants and hydraulic oils in CNC machines

BUFFER TANKS IN THE DAIRY INDUSTRY

Boetech BV, the dairy industry automation specialists understand the requirement for effective use of liquid level sensors in buffer tanks.

“Level sensor: Mandatory on the larger buffer tanks and when a pressure system is used. Boetech shall not be responsible for any loss of milk if no level sensor has been installed in a buffer tank.”

Level Measurement

food & beverage industry

USING sick LFP Inox level sensor

➡ Did you know? T&D Hazardous Area team are trained and certified in the specification and sale of flameproof and explosion-proof equipment, including Crowcon Gas Detectors.