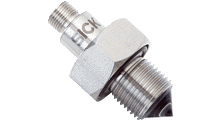

SICK MHF15 Level Sensors

SICK SENSORS

SICK MHF15 Level Sensors

- Robust level monitoring in liquid without additional requirements

- Small, compact design, no medium calibration required

- Process temperature up to 55 °C, process pressure up to 16 bar

- IP 67 and IP 69K enclosure rating

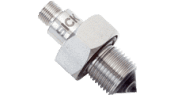

- Process connection G ½

- Highly medium resistant due to stainless steel housing 1.4404, polysulfone apex

- Output available as PNP or NPN transistor

- FDA-compliant, UL

SICK MHF15 – BENEFITS

- Small, compact sensor ideal for difficult installation conditions with limited space

- Quick commissioning without medium calibration saves time and money

- No moving mechanical parts reduce maintenance and eliminate the need to recalibrate, even after long periods of use

SICK MHF15 Level Sensors are compact optical level limit switches that are simple to commission. The MHF15 level sensor is based on SICK’s energetic photoelectric proximity sensor technology, which has been tested and optimised over many years. The design of the MHF15 is simple, reliable and rugged providing reliability even in adverse process conditions.

The use of FDA-compliant materials in an EHEDG-certified design means that the MHF15 can be relied upon for optimum and unrestricted cleaning, even in applications with the most stringent hygiene requirements.

The optical technology makes the MHF15 particularly suitable for use with water-based media.

SICK Level Sensors – Continuous Level Measurement & Point Level Measurement

SICK MHF15 – TECHNICAL DATA

| Measurement principle: | Optical level switch |

| Detection principle: | Contact |

| Medium: | Fluids |

| Measurement: | Switch |

| Process temperature: | –25 °C … +55 °C |

| Process pressure: | –0.5 bar … 16 bar |

| Output signal: | 1 x PNP / 1 x NPN |

LIQUID LEVEL SENSOR APPLICATIONS

- Level monitoring in aqueous and water-based liquids

- Dry running protection for pumps

- Level control in cleaning system flushing units

➡ Did you know? T&D Hazardous Area team are trained and certified in the specification and sale of flameproof and explosion-proof equipment, including Crowcon Gas Detectors.