What Is A Fan?

Published 22 Apr 2020

-

Article Written By Woodcock & Wilson | 1 of 6 Articles

Woodcock & Wilson are specialist manufacturers of independently certified ATEX fans and IECEx industrial fans for the ventilation of hazardous area locations and potentially explosive atmospheres.

Below is Part 1 in a series of 6 Articles by Woodcock & Wilson discussing fans, the laws, common problems, troubleshooting the main performance issues and getting your fan started again if you encounter any issues.

What is a Fan?

A fan is a machine for transferring energy into moving air. The performance of a fan can be described in terms of Volume Flow, Pressure, Power Absorbed & Efficiency.

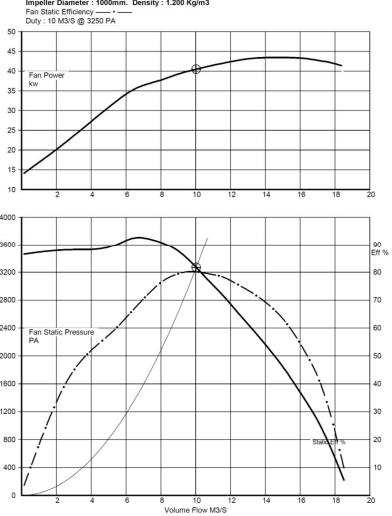

Fan Static Efficiency

Three Main Fan Types

- Axial Flow

- Centrifugal

- Mixed Flow

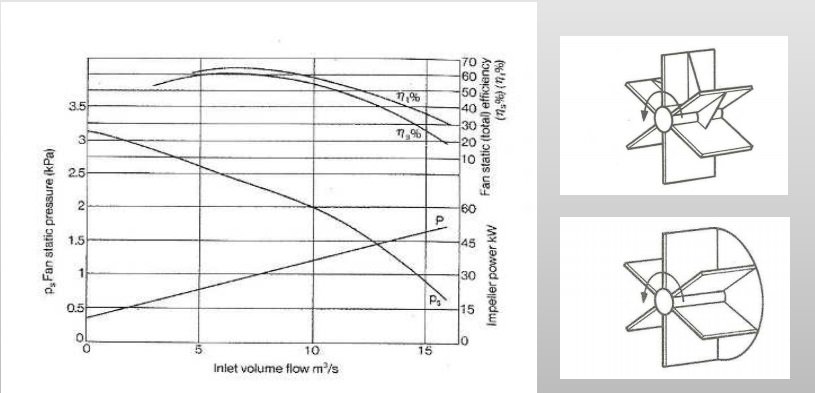

Axial Fans

Air enters and exits axially.

- Long case, Short case or Plate mounted

- Tubular Case – can be as with a portable man cooler, ducted on either inlet, outlet or both inlet & outlet

- Bifurcated Axial – internal tunnel or pod for mounting the motor out of the airstream-used for hot or corrosive gasses

Axial Fans

It may come as a surprise that most modern jet engines incorporate a large axial fan. Here the Rolls Royce Trent first stage fan can be seen in all its glory. The fan contributes to around 90% of the thrust generated by the engine and absorbs around 100 MW of power….that’s a big power fan!!

Industrial axial fans come in all shapes and sizes…here are some of them:

Axial Fan Examples

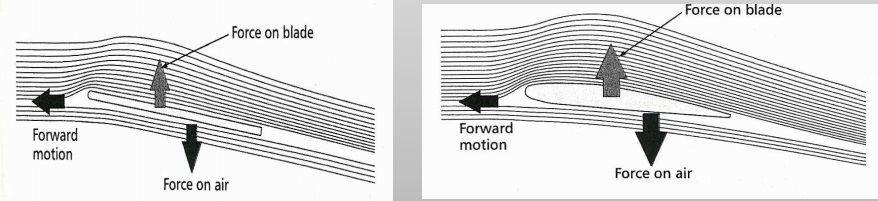

Principles of Operation

Axial fans work by generating lift within the rotating blades. Newton’s third law states that for every action there exists an equal & opposite reaction. In this case the upward lift force on the blade is balanced by an equal and opposite force making the air flow in the opposite direction.

Principles Of Operation

- Generally suited for moving large volumes of air at low pressures

- Generally low efficiencies- 50%-60%. Larger special designs can achieve static efficiencies in the upper 80’s %

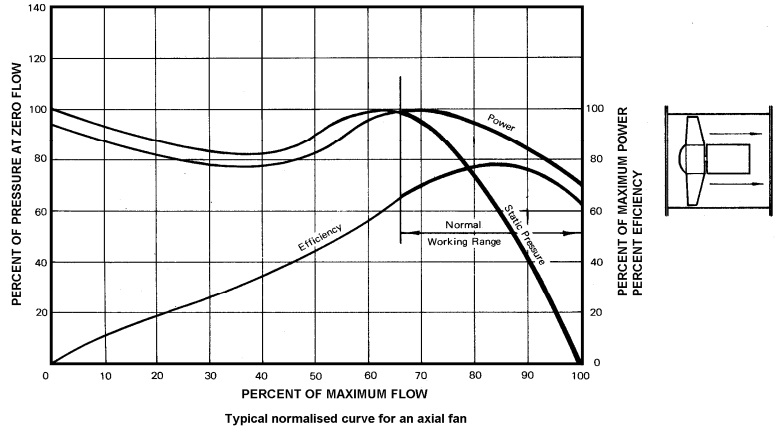

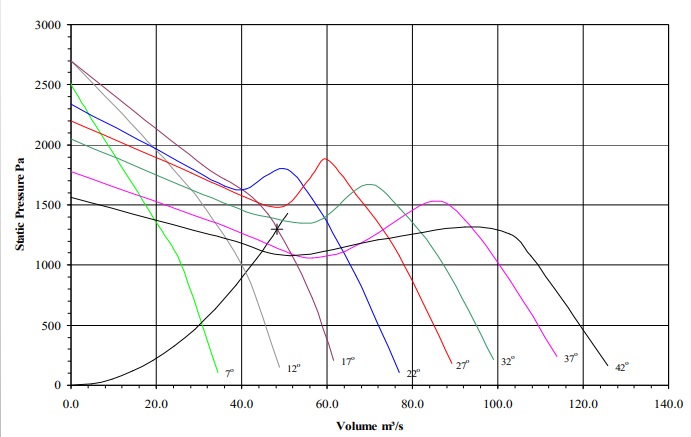

- Larger pitches can have a pronounced stall & can be inherently unstable if selected too far to the left of the fan curve. Should be selected well to the left of peak pressure or select a larger fan at a lower pitch angle

Typical Normalised Curve For An Axial Fan

Static Pressure of Axial Fan

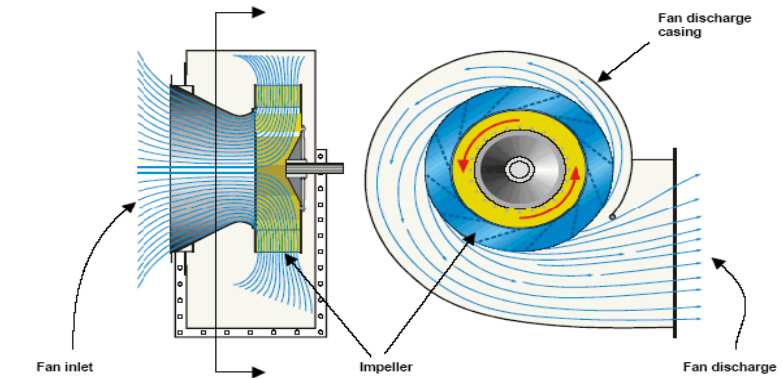

Centrifugal Fans

Air enters the fan axially and exits at 90°.

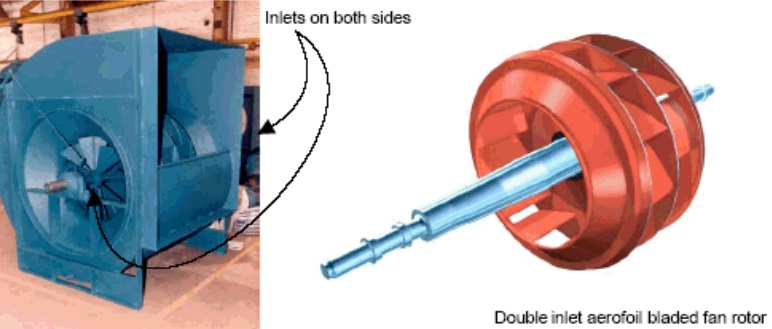

- Single inlet-all air is drawn in through one inlet. (SISW)

- Double inlet-equal amounts of air drawn in through two opposing inlets. (DIDW)

- Fan case is an expanding volute shape, which assists static pressure regain and directs the airflow in one direction

Centrifugal Fans

Centrifugal Fans in situ

Double Inlet Double Width (DIDW)

Centrifugal Fan

DIDW Centrifugal

Principles of Fan Operation

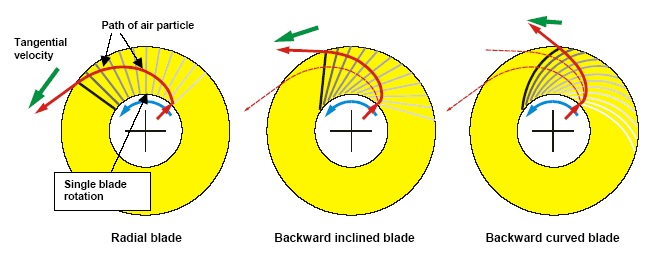

Unlike axial flow fans, which rely on aerodynamic lift from blades, centrifugal fans rely on dragging air round in circles and using centrifugal force to generate air flow.

Principles Of Operation

Velocity Profile Through A Centrifugal Fan

Different types of centrifugal fan impellers:

- Backward bladed

- Forward curved

- Radial bladed

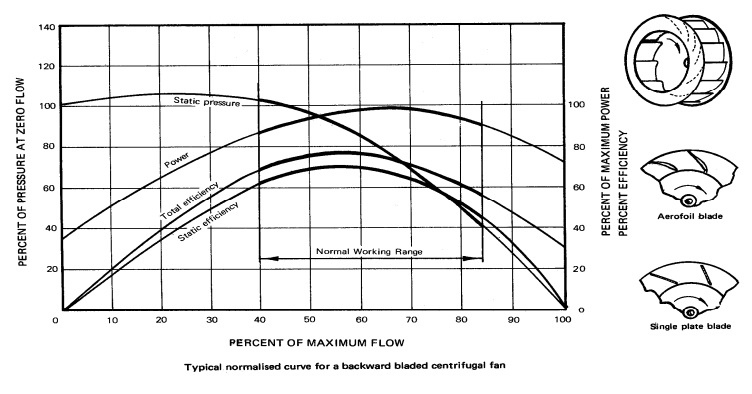

Backward Bladed

- Flat backward inclined, backward curved & double skin aerofoil

- High efficiency > 80% static

- Non overloading power characteristic-power absorbed reaches a peak near the maximum efficiency & then becomes lower towards higher flows

- Can exhibit stall characteristics to the left of peak pressure-this could result in instability & vibration. Fan selection point should always be on the steep part of the curve to the right of peak pressure

- Can cope with medium erosive gasses in arduous applications

- Used in HVAC and industrial applications

Backward Bladed Impeller Characteristic & Examples

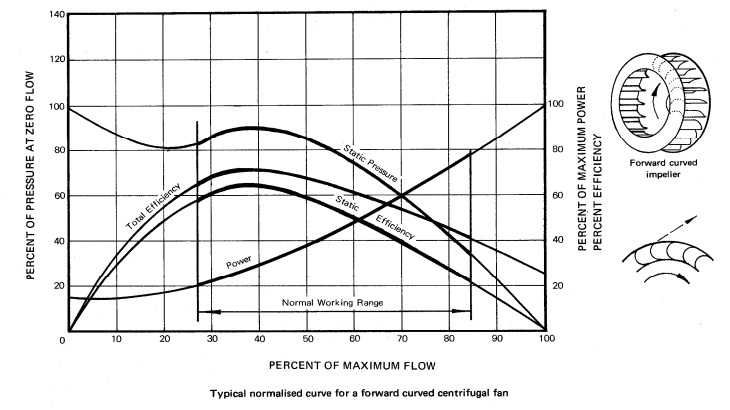

Forward Curved (Multivane)

- Comparable selections often give a smaller diameter fan than a backward inclined

- Usually used for large flow rates, low pressure HVAC and air handling unit applications

- Volume / Pressure characteristic less steep than backward bladed fan

- No pronounced stall, so can operate over a wider span of the characteristic curve

- Exhibits overloading power characteristic – power rises continually towards higher flows

- Poor efficiency-typically 50% to 60%

Forward Curved (Multivane) Characteristic & Impeller

Radial Bladed (Paddle Bladed)

- Open paddle, Backplate paddle or Shrouded paddle

- The unshrouded version has the highest mechanical strength of all centrifugal types

- Suitable for heavy dust burdens and high temperatures

- The characteristic is stable over the whole range of flows

- Exhibits overloading power characteristic – power rises continually towards higher flows

- Narrow types are suitable for high pressure applications such as pneumatic conveying

Radial Bladed (Paddle Bladed)

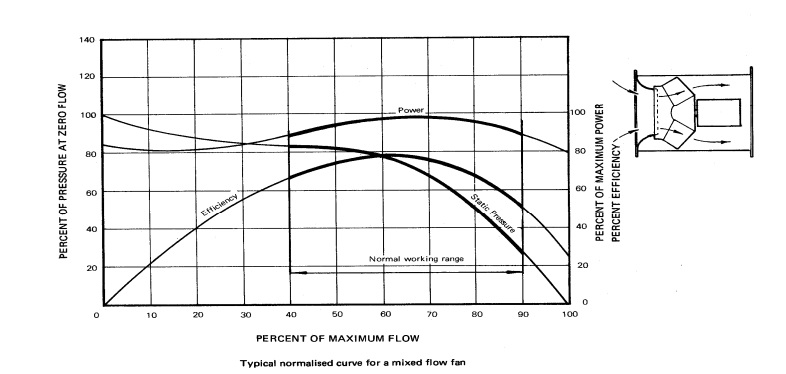

Mixed Flow Fans

- Hybrid centrifugal and axial fan

- Impeller rotation imparts both an axial & a centrifugal component. The flow from the impeller discharges into an annular chamber

- Where stationary vanes reduce the whirl component and recover static pressure

- Higher pressures achievable than an axial fan

- Mixed flow fan impellers, which are shrouded are more robust than an axial fan and have a less severe stall

Mixed Flow Fans Characteristic

See further information about the Exstream range of Portable ATEX Certified Fans

Experts In Equipment for Explosive Atmospheres with ATEX & IECEx Certification

LEADERS IN ATEX INNOVATION

T&D are your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to your UK and international projects.

Key Product Groups

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery