Multipoint Earthing Control System | ATEX Certified | StuvEx MGS01

Thorne & Derrick | Approved Supplier of Static Earthing, Grounding & Bonding Systems | ATEX Certified Products & Solutions

Static Control for Explosion Protection of Assets & Operators in Hazardous Area Locations

ATEX Certified

Multipoint Earthing Control System | StuvEx MGS01

Safe Earthing of Vessels & Drums for Hazardous Areas & Explosion Protection

The MGS01-V1 earthing control system is ATEX Certified to provide static earthing control and dissipation of accumulated static electricity in hazardous area industries with potentially explosive atmospheres, this includes Zone 1 (21) and Zone 2 (22) flammable gas and combustible dust applications.

The Multipoint Earthing Control System is suitable for simultaneous earthing of one to up to 10 conductive objects. When loading or unloading flammable, conductive liquids or powders, electrostatic charges can be generated. If the electrostatic energy generated is sufficiently large, a discharge spark may cause a fire or explosion. This risk is avoided by connecting all conductive parts to earth.

The earthing system which is manufactured by StuvEx and distributed by Thorne & Derrick, forms part of a preventive operating system in a process plant for use in hazardous areas with potentially explosive atmospheres.

➡ Thorne & Derrick together with StuvEx supply Static Bonding Clamps, Cables & Connectors to the hazardous area EX industries with over 35 years experience.

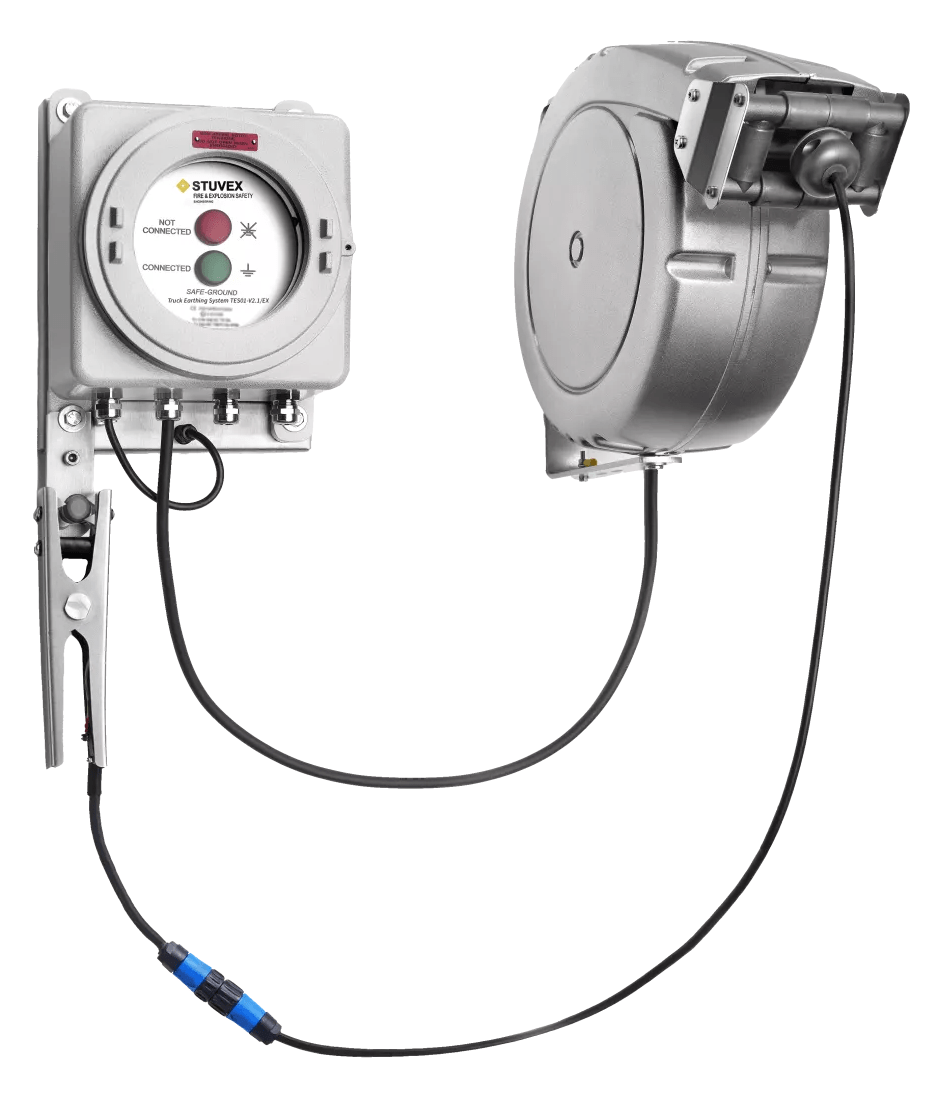

The Multipoint Earthing Control System MGS01 forms part of the range of static earthing products and systems – the Earthing Control System consists of a power box, one up to 10 resistance control boxes, one up to 10 loose cable(s) or coiled cable(s), one up to 10 earthing clamps, supplied with or without connector set.

Earthing Control System for Hazardous Areas

Benefits

Specially designed and developed for safe earthing of vessels and drums, among others, the StuvEx MGS01-V1 earthing control system offers the following advantages:

- Connection possibility for up to 10 objects to be grounded

- Safe electrostatic discharge of connected objects

- Low resistance( < 10 Ω)

- Signalled (green) for local status indication

- Signal LEDs (red and green) for local release indication

- Potential-free contact release charging or discharging process

- ATEX and IECEx certified

- Complies with IEC/TS60079-32-1 and NFPA77

- Safety class SIL 2

Hazardous Area Earthing Solution

The MGS01-V1-RCB belongs to device Group II category 2GD and can be used in a hazardous area zone 1 or 2 (gas) or in a zone 21 or 22 (dust). The MGS01-V1-PB belongs to equipment group II category 3GD and may be used in zone 2 (gas) or zone 22 (dust) potentially explosive atmospheres.

|

|

|

| SG/E-MGS01-V1 EX with spiral cable, earthing clamp and ReConn | SG/E-MGS01-V1 EX PB | SG/E-MGS01-V1 EX RCB |

MGS01-V1 Earthing Control System Operation

The MGS01 earthing system consists of an MGS01-V1-PB (Power Box) and one or more MGS01-V1-RCB (Resistance Control Box). The earthing system is designed to ground conductive objects in a safe and controlled way using an earthing clamp to ensure safe loading or unloading operations. The earthing system forms part of a preventive system in process installation.

Earthing Control Unit MGS01-V1

The MSG01-V1 earthing system consist of:

- One Power Box, type MGS01-PB

- One up to 10 Resistance Control Boxes, type MGS01-RCB One up to 10 loose cable(s) or coiled cable(s), type SPxx-HD

- One up to max. 10 earth clamp(s), type CSS1 or CMS1, supplied with or without connector set

|

|

| ATEX Stainless Steel Earthing Clamp – StuvEx Safe-Ground CMS1 | ATEX Spiral Earthing & Grounding Cables – StuvEx Safe-Ground SP1 |

Cable or Spiral Cable

You can choose between flat cable (10 m), spiral cable (3 m – 5 m – 10 m) to connect the MGS01-V1 to the objects to be earthed.

Active Earthing Clamp

With active clamps, the two clamping jaws are isolated from each other as well as isolated from the clamping body itself. As long as the clamps are not connected to a conductive object, the circuit between the clamping jaws remain open and no current can flow. Once the clamp is attached to the earthing point of the truck, the circuit is closed.

How The Multipoint Earthing Control System Works?

The MGS01 earthing system, when connecting the earthing clamp, will discharge the electrostatic charge present on the object to earth in a safe and controlled manner. After discharging, the object is connected to earth by the MGS01 earthing system with a low-impedance connection As long as the device has this low resistance (< 10 Ohms), the release contact is switched and a green LED will illuminate.

During unloading or charging, the connection is permanently monitored. If the connection is broken, a red LED will light. Via an interlock contact, the MGS01 earthing system can be connected to the process plant and automatically interrupt unloading or loading. Restarting the cycle is done by disconnecting and reconnecting the earthing clamp.

StuvEx | Manufacturer of Static Earthing Solutions for hazardous areas for companies handling flammable and combustible products | ATEX, IECEx, SIL Compliant | Distributed by Thorne & Derrick International based in the UK.

STATIC GROUNDING SYSTEM GENERAL CHARACTERISTICS

| Power Supply | 100-240 V AC, 50/60 Hz |

| Operating Temperature | -25°C to +60°C |

| Humidity | 95% at 20°C in non-condensing conditions |

| Protection Class | IP55 |

| Ground Resistance | ≤ 10 Ω |

| Monitoring Circuit | Intrinsically safe |

| Safety Class | SIL 2 |

MGS01-PB Technical Data

ATEX Certified for Hazardous Areas

| ATEX Information | Certified for use in hazardous area zones 2 (gas), zone 22 (dust) and non-risk environments |

| ATEX Marking | II 3GD Ex ec nC IIC T4 Gc Ex tc IIIC T135°C Dc -25°C ≤ Ta ≤ +60°C |

| Housing | Aluminium, coated RAL7001 (silver-grey) |

| Dimensions (h,l,w) | 230 x 400 x 111 mm |

| Weight | 5.2 kg |

| Cable Glands | 1 x power supply, M16 x 1.5 10 x connection for MGS01-RCB, M16 x 1.5 1 x connection for multi-signalling cable, M25 x 1.5 |

| Interlock contact | Max. 10 potential-free, NO, 1 A, 30 V DC 1 x status PSU (power supply unit), NO, 1 A, 30 V DC |

MGS01-RCB Technical Data

| ATEX/IEXEx Information | Certified for use in zones 2 (gas), zone 22 (dust) and non-risk environments |

| ATEX/IECEx Marking | II 2(1)GD Ex mb[ia Ga] IIC T6 Gb Ex mb[ia Da] IIIC T85°C Db -25°C ≤ Ta ≤ +60°C |

| Housing | Aluminium, coated RAL7001 (silver-grey) |

| Dimensions (h,l,w) | 60 x 100 x 190 mm |

| Weight | 1.43 kg |

| Cable Glands | 1 x 4-pin connector, F, CA 3GD (for connection of flat cable or spiral cable) 1 x connection cable to MGS01-PB, 4 x 0.75 mm², 5, 10 or 20 m |

| Interlock contact | 1 potential-free contact, NO, 1 A, 30 V DC |

Earthing Clamp Accessories

| Clamp * | II 1 GD Ex c, ia IIC, IIIC T6 T85°C passive EEx i component for use in zones 0, 1, 2, 20, 21, 22 |

| CSS1 | 160 mm stainless steel clamp, jaw opening 3-30 mm, -10°C to +80°C, integrated strain relief |

| CMS1 | 210 mm stainless steel clamp, jaw opening 3-30 mm, -10°C to +80°C, integrated strain relief |

| Cables * | II 2 GD Ex c, ia IIC, IIIC T6 T85°C passive EEx i component for use in zones 1, 21 |

| C01/10 | 3G 1,5 mm² straight cable without reel, UV and oil resistant cable sheathing, flame retardant, -25° to + 60°C, black, available length: 10 m |

| SP1-HD | 3G 0,75 mm² spiral cable, UV and oil resistant cable sheating, flame retardant, -30° to +80°C, blue, available lengths: 3 m, 5 m, 10 m |

| Connector Set | M+F, plastic, blue IP65, -40°C to +100°C, with integrated strain relief |

| RBC Mounting Plate | Stainless steel mounting plate for RCB |

| Safe-Ground ReConn01 | Test device, for safe ground control units, incl. test cable and clip |

* available with or without premounted connector

Thorne & Derrick, Experts in Equipment for Explosive Atmospheres, are the Exclusive Channel Partner for StuvEx static earthing, grounding and bonding products in the UK including ATEX and IECEx certified systems, clamps, cables and connectors.

Static Earthing, Grounding & Bonding Systems

For Hazardous Areas zone 1 (21) & Zone 2 (22) | ATEX Certified

Product Overview

Should you require any customer support or service to enable the selection or specification of the correct Static Earthing Systems for use in explosive atmosphere locations in the hazardous area industries please do not hesitate to contact us.

StuvEx are an international manufacturer of a complete range of Static Earthing, Grounding & Bonding Solutions with ATEX & IECEx Certification for use in hazardous areas; this includes static bonding, grounding and earthing clamps, cables and reels for the safe control of electrostatic hazards and risks in Zone 1 / Zone 2 (Flammable Gas) and Zone 21 / Zone 22 (Combustible Dust) locations.