Fisher 8580 Butterfly Valve – Rotary Valves

Fisher 8580 Valve Butterfly Valve – Rotary Valves

Fisher 8580 Valve is a high performance butterfly valve that offers excellent throttling performance with a high cycle life and rugged reliability.

The valve body of the Fisher 8580 meets PN 10 through PN40, CL150 and CL300 whilst the face to face dimensions meet EN 558, API 609 and MSS-SP68 standards.

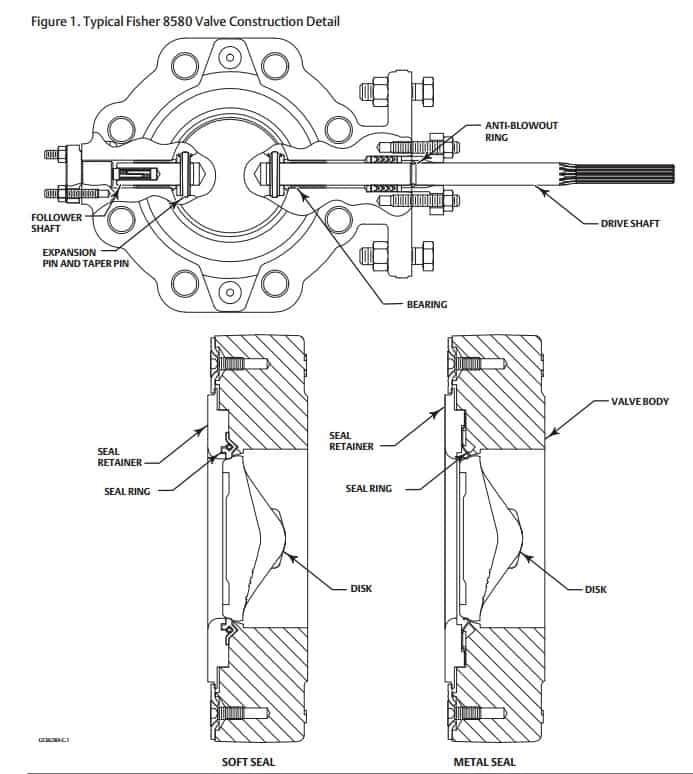

The 8580 butterfly valve features an eccentrically mounted disk with either soft or metal seal, providing capability for enhanced shutoff. The interchangeable sealing technology allows for the same valve body to accept both soft and metal seals.

Fisher 8580 Valve Butterfly Valve – Product Features

- Global Standards – the valve meets API, ASME, and EN standards, making it suitable for use in all world areas

- PEEK/PTFE bearing as standard – the PTFE-lined PEEK bearing is a low friction, low wear bearing. It allows the valve to operate under high pressure drops for a high cycle life while maintaining low torque. The “drop-in” bearing design enables fast, easy maintenance

- Spline-ended Shaft – the splined shaft with clamped lever and single-pivot linkage reduces lost motion between the actuator and the valve shaft

- Improved shaft-disk pinning – the improved expansion pin system ensures there is a positive, durable connection between disk and shaft. This connection reduces backlash and wear in the drive system, optimizing long-term performance. It also makes disassembly for maintenance quick and simple with no need for special tools

- Easy Installation – line-centering clips engage the line flange bolts to simplify installation and provide for centering of wafer-style valves in the pipeline. End connections are compatible with EN and ASME standards

- Excellent Shutoff – both the metal and soft seal rings have pressure-assisting sealing action that ensures tight shutoff regardless of pressure drop

- Long Seal Life – the opening and closing path of the eccentric disk minimizes disk contact with the seal ring, thereby reducing seal wear, undue friction, and seating torque requirements

- High Temperature Capability – the valve will operate at elevated temperatures, with the appropriate trim components

- Excellent Emissions Capabilities – the optional ENVIRO-SEALt packing systems, are designed with very smooth shaft surfaces and live-loading to provide improved sealing, guiding, and loading force transmission. The seal of the ENVIRO-SEAL system can control emissions to below 100 ppm (parts per million)

FISHER 8580 VALVE BUTTERFLY VALVE

Specifications and Materials of Construction

| Specifications | EN | ASME | |

| Valve Body Sizes | DN 50, 80, 100, 150, 200, 250, and 300 | NPS 2, 3, 4, 6, 8, 10, and 12 | |

| Pressure Rating | PN 10 to 40 per EN 12516-1 | CL150 / 300 per ASME B16.34, CL150-600 for NPS 2 | |

| Valve Body Materials | EN 1.0619 steel | WCC steel | |

| EN 1.4409 stainless steel | CF3M (316L) stainless steel | ||

| LCC | LCC | ||

| CW2M(1) | CW2M(1) | ||

| M35-2(2) | M35-2 | ||

| Disk Materials | PTFE or RPTFE(4) Sea | EN 1.4409 stainless steel | CF3M stainless steel |

| CW2M | CW2M | ||

| Metal or UHMWPE(3) Seal | M35-2 | M35-2 | |

| End Connections | Mates with raised-face flanges per EN 1092-1 | Mates with raised-face flanges per ASME B16.5 | |

| Valve Body Style | Wafer (flangeless) and lugged with tapped or through holes | ||

| Face-to-Face Dimensions | Meets MSS SP68, API 609, and EN 558 standards | ||

| Shutoff | PTFE, RPTFE, or UHMWPE seal ring – Class VI per ANSI/FCI 70-2 and IEC 60534-4 | ||

| S31600 (316 SST) seal ring – Class IV per ANSI/FCI 70-2 and IEC 60534-4 | |||

| Flow Direction | Standard (forward flow) is with the seal retainer facing upstream; reverse flow is permissible for soft seals only | ||

| Flow Characteristic | Approximately linear | ||

| Disk Rotation | Counterclockwise to open (when viewed from actuator side of valve body) through 90 degrees of disk rotation | ||

1. This material is not listed in EN 12516-1 or ASME B16.34. See figure 6 for pressure/temperature ratings. 2. This material is not listed in EN 12516-1. See figure 6 for pressure/temperature ratings. 3. UHMWPE stands for ultra high molecular weight polyethylene. 4. RPTFE is a reinforced PTFE seal.

Fisher 8580 Butterfly Valve – Rotary Valves – Construction

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Installing Fisher 8580 Butterfly Valve

Fisher 8580 butterfly valves should be installed with the shaft horizontal in a normal flow direction – horizontal installation will enhance valve performance as process fluids will sweep entrained solids from valve surfaces preventing particle build-up on the valve seals.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.