Fisher 8590 Butterfly Valve – Rotary Valves

Fisher 8590 Valve Butterfly Valve – Rotary Valves

Fisher 8590 Valve is a high performance butterfly valve that can maintain tight shutoff for use under extreme pressure and temperature conditions.

The splined shaft of the Fisher 8590 combines with a variety of spring-and-diaphragm or pneumatic piston actuators to make the 8590 a reliable, high-performance butterfly valve for a variety of throttling and on-off applications in the various process industries.

The 8590 valve can be supplied with one of several dynamic seals that can be used in a variety of demanding applications.

Fisher 8590 Valve Butterfly Valve – Product Features

- Shaft Versatility – this valve will meet your actuator needs with a choice of splined, square, or keyed shaft connections

- Excellent Shutoff Integrity – the pressure-assisted seal design provides tight shutoff and permits the use of smaller., less expensive actuators in applications requiring full ASME B16.34 shutoff capbilities

- Excellent Emissions Capabilities – optional ENVIRO-SEAL packing systems are designed with very smooth shaft surfaces and live-loading to provide improved sealing, guiding, and loading force transmission. The seal of the ENVIRO-SEAL system can control emissions to below 100 ppm (parts per million)

- Sour Service Capability – trim and bolting materials are available for applications involving sour liquids and gases. These constructions comply with NACE M0175-2002, MR0175-2003, MR0103, and MR0175 / ISO 15156

- Easy Installation – the valve body self-centers on the line flange bolts as a fast, accurate means of centering the valve in the pipeline

- Reliable Flange Gasketing Surface – seal retainer screws are located so there is no interference with the sealing function of either flat sheet or spiral wound line flange gaskets.

- True Bidirectional Shutoff Performance – a feature of the valve design is that the torque necessary to open and close the valves is the same regardless of the direction in which the differential pressure is applied

FISHER 8590 VALVE BUTTERFLY VALVE

PRODUCT Specification

| Specifications | ASME |

| Valve Body Size | NPS 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24 |

| Pressure Rating | CL600 per ASME B16.34 |

| Valve Body Materials | WCC or CF8M (std) |

| LCC, CD3MN, M35-2, and CW2M | |

| Disk Materials | CF8M (std), CD3MN, M35-2, and CW2M |

| Disk Edge Coating | Chrome Plate (std) Chrome Coat Chromium Carbide Coating |

| End Connections | Mates with RF Flanges per ASME B16.5 Optional construction mates with RTJ Flanges per ASME B16.5 |

| Valve Body Style | Lugged (Single Flange) or Lugged with drilled through flange holes |

| Face-to-Face Dimensions | Meets MSS SP68, API 609, ASME B16.10, and EN 558 standards |

| Shutoff | Soft Seal: Class VI |

| Metal Seal: Class IV, reverse direction only | |

| Phoenix III Seal: Class VI; reverse direction preferred, forward direction optional | |

| High Pressure Seal: Class VI, reverse direction only | |

| Flow Direction | Standard (reverse flow) is with the flow into the shaft side of the disk |

| Flow Characteristic | Linear |

| Disk Rotation | Clockwise (CW) to close |

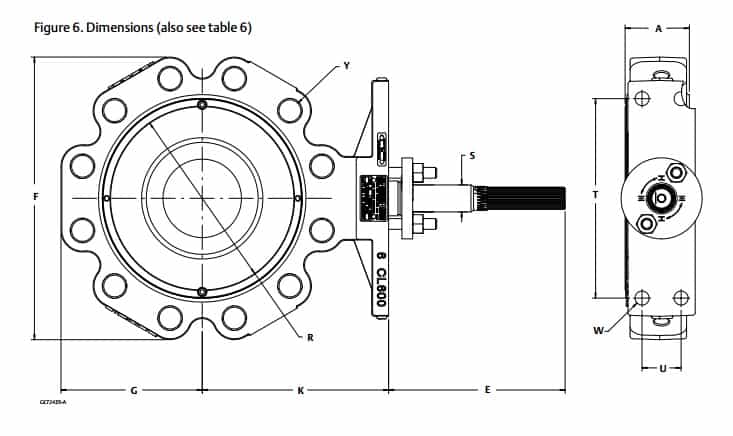

FISHER 8590 VALVE BUTTERFLY VALVE Dimensions & Weights

| Valve Size | A | E | F | G | K | R | S(1) | T | U | Y(2) | W(2) | Approximate Weight |

| mm | kg | |||||||||||

| NPS 3 | 52 | 187 | 198 | 98 | 123 | 127 | 15.9 | 117 | – | 3/4-10 | 1/2-13 | 10.8 |

| NPS 4 | 62 | 214 | 259 | 128 | 150 | 157 | 19.1 | 152 | 32 | 7/8-9 | 1/2-13 | 21.6 |

| NPS 6 | 76 | 208 | 333 | 166 | 220 | 216 | 31.8 | 235 | 46 | 1-8 | 5/8-11 | 45.5 |

| NPS 8 | 102 | 208 | 407 | 241 | 234 | 270 | 38.1 | 235 | 46 | 1-1/8-8 | 5/8-11 | 80.2 |

| NPS 10 | 116 | 356 | 506 | 312 | 302 | 324 | 44.5 | 273 | 51 | 1-1/4-8 | 3/4-10 | 157 |

| NPS 12 | 140 | 356 | 553 | 339 | 332 | 381 | 50.8 | 273 | 51 | 1-3/8-8 | 3/4-10 | 213 |

| NPS 14 | 157 | 356 | 597 | 370 | 348 | 413 | 63.5 | 337 | 76 | 1-1/2-8 | 7/8-9 | 281 |

| NPS 16 | 178 | 356 | 678 | 408 | 386 | 470 | 63.5 | 337 | 76 | 1-5/8-8 | 7/8-9 | 395 |

| NPS 18 | 198 | 508 | 735 | 451 | 427 | 533 | 76.2 | 533 | 127 | 1-5/8-8 | 1-1/4-8 | 563 |

| NPS 20 | 216 | 508 | 807 | 478 | 446 | 584 | 76.2 | 533 | 127 | 1-5/8-8 | 1-1/4-8 | 721 |

| NPS 24 | 230 | 508 | 933 | 544 | 413 | 692 | 76.2 | 533 | 127 | 1-7/8-8 | 1-1/4-8 | 1000 |

Fisher 8590 Butterfly Valve – Rotary Valves – Dimensions

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Installing Fisher 8590 Butterfly Valve

Fisher 8590 butterfly valves should be installed with the shaft horizontal in a normal flow direction – horizontal installation will enhance valve performance as process fluids will sweep entrained solids from valve surfaces preventing particle build-up on the valve seals.

Fisher Valves Typical Industries Include Power, Petrochem, Oil & Gas

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson process industrial group.