COMAH | Explosive Atmospheres & Risk Mitigation by Product Innovation

Published 24 Nov 2020

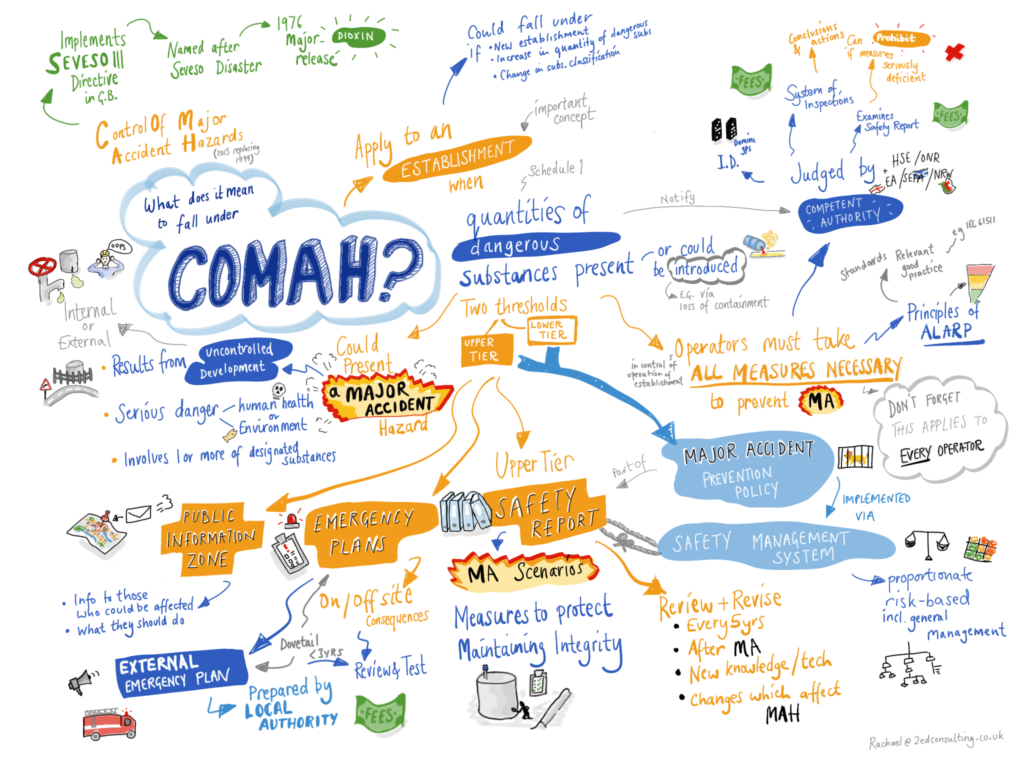

Image by Rachael Cowin

COMAH

-

uploaded by Terry McDonald | Experts in Equipment for Explosive Atmospheres

According to the UK Health & Safety Executive (HSE) the Control of Major Accident Hazards (COMAH) Regulations ensure that businesses: “take all necessary measures to prevent major accidents involving dangerous substances.”

These dangerous substances are broadly categorised as explosive gases, vapours or mists and combustible dusts – they are designated as potentially explosive atmospheres and the degree of risk is determined in the UK and Europe currently according to the ATEX Directive based on a categorised “Zone” approach detailed below.

Additionally, The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) provides a specific legal requirement to carry out a hazardous area study, and document the conclusions, in the form of such hazardous area zones.

COMAH locations must undergo classification of plant into hazardous areas, and the systematic identification and control of ignition sources to prevent major accident.

Hazardous areas are defined in DSEAR as “any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers”. In this context, ‘special precautions’ is best taken as relating to the construction, installation and use of apparatus – this could include electrical, instrumentation or mechanical equipment providing heating, lighting, or ventilation to the plant.

To ensure site and process safety all equipment located in hazardous areas must be correctly specified and certified according to international classifications such as ATEX.

A Guidance Document published by the HSE can be downloaded here and aims to help dutyholders comply with the Control of Major Accident Hazards (COMAH) Regulations 2015. Furthermore, the COSHH e-tool provides advice on controlling the use of chemicals for a range of common tasks and controlling associated health risks during industrial processes such as mixing or drying.

This article ‘Contains public sector information published by the Health and Safety Executive and licensed under the Open Government Licence’.

Know the Zone

Hazardous areas are classified into zones based on an assessment of the frequency of the occurrence and duration of an explosive gas atmosphere, as follows:

- Zone 0: An area in which an explosive gas atmosphere is present continuously or for long periods;

- Zone 1: An area in which an explosive gas atmosphere is likely to occur in normal operation;

- Zone 2: An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time.

Various sources have tried to place time limits on to these zones, but none have been officially adopted. The most common values used are:

- Zone 0: Explosive atmosphere for more than 1000h/yr

- Zone 1: Explosive atmosphere for more than 10, but less than 1000 h/yr

- Zone 2: Explosive atmosphere for less than 10h/yr, but still sufficiently likely as to require controls over ignition sources.

Recommendations

The following companies provide Hazardous Area Studies to ensure COMAH sites are compliant to their obligations according to DSEAR.

- Sigma-HSE

- C&P Engineering Services

- PDA Philip Durrant Associates

- CATCH Technical Services

- Abbott Risk Consulting

- Safetec UK Ltd

- Mabbett

Thorne & Derrick are leaders in ATEX & IECEx Product Innovation providing Lighting, Heating, Ventilation and Security in Explosive Atmospheres.

Talk to us today about how we can improve operational safety, energy efficiency and optimise productivity in your hazardous areas.

We are your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for your UK and international projects.

>>> GO TO INNOVATION <<<

EXPERTS IN EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick International, based in the UK, are Approved Vendors to most Oil & Gas exploration and production companies and international EPC contractors – since 1985, T&D have established a solid reputation based on Service, Integrity and Trust.

From our distribution locations with 50,000+ sq feet warehouse capacity and a £2.5 million stock, we can supply many products by next day delivery – our key sectors are the process, pharmaceutical, chemical, utility, food/beverage, renewable and oil/gas industries.