Fan System Problems

Published 23 Apr 2020

- Article Written By Woodcock & Wilson | 3 of 6 Articles

Woodcock & Wilson are specialist manufacturers of independently certified ATEX fans and IECEx industrial fans for the ventilation of hazardous area locations and potentially explosive atmospheres.

Below is Part 3 in a series of 6 Articles by Woodcock & Wilson discussing fans, the laws, common problems, troubleshooting the main performance issues and getting your fan started again if you encounter any issues.

Fans will only meet the duty point shown on the performance curve under “ideal” installation conditions. Ideal conditions are seldom obtainable in practice consequently there will always be some “SYSTEM EFFECT”.

Factors That Influence Fan System Effect

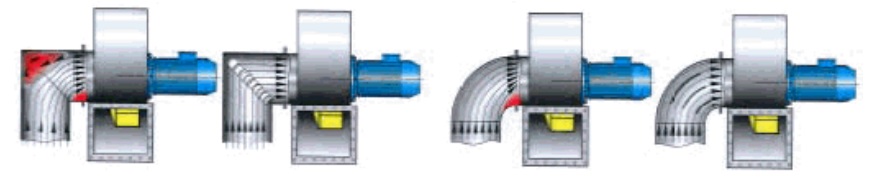

- Elbow or bend too close to fan inlet or outlet

- Abrupt duct transition

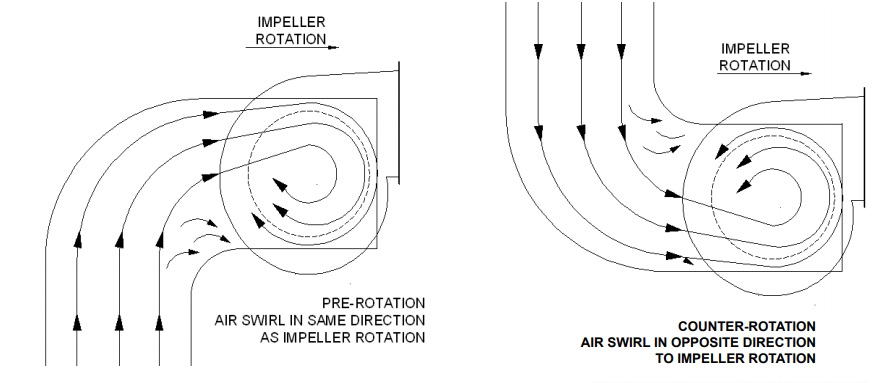

Pre swirl of the incoming air due to duct design. (Swirl in same direction as rotation). - Dampers not fully open

- Damper location

- Poorly designed fan drives – large drive pulley – solid rather than spoked

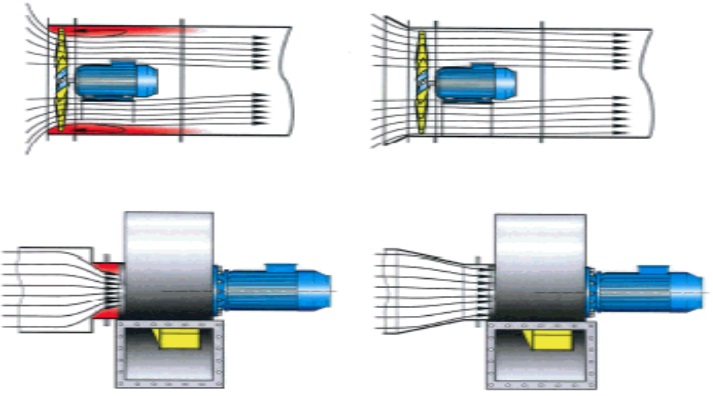

- Fan inlet or outlet too close to wall or bulkhead

- Fan inlet box design

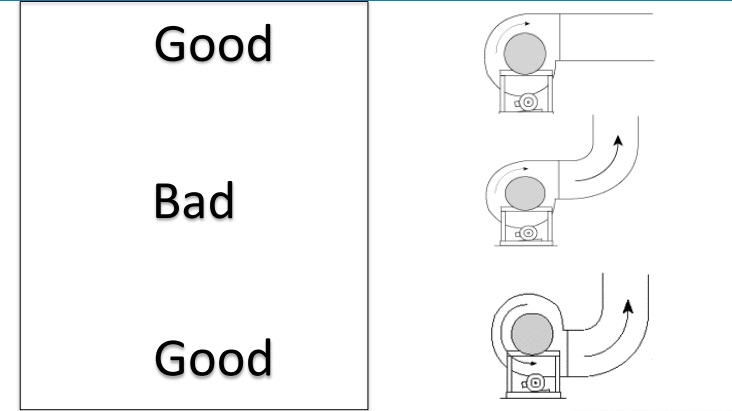

- Bend orientations at discharge

- Free discharge – abrupt expansion

- Weather cowls and hoods

Some Do’s & Don’t’s When For Fan Installations

Fan Discharge Orientation

Fan Inlet Swirl

Experts In Equipment for Explosive Atmospheres with ATEX & IECEx Certification

LEADERS IN ATEX INNOVATION

T&D are your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to your UK and international projects.

Key Product Groups

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery