High Pressure Heated Hose Technology From Eltherm

Published 01 Feb 2017

- By Chris Dodds : estimated reading time 4 minutes

T&D specialise in providing specialist heating for industrial and hazardous areas including Eltherm’s heat tracing cables and heated hoses.

Today T&D present a guest blog from Eltherm’s Commercial Manager Daniel Court on the benefits of using heated hoses.

Handling of pressurised liquids, gasses and viscous substances at elevated process temperatures is a very common requirement throughout the manufacturing and process sectors, but all too often in a scheme design, the linkage between a trace heated pipework system and the point of dispensing of the heated product is an aspect which is not considered during the design process, or is left for addressing once the rest of the system is built and in place. The solution to this issue is a speciality of Eltherm.

Eltherm pressure hoses can maintain stationary or flowing product at temperatures up to 250°C in a PTFE hose and with pressures up to 500 bar; depending upon the diameter of the hose and the required temperature. With a stainless steel carrier hose, temperatures of 500°C are in fact possible.

Flexibility is often a crucial aspect of such applications, whether simply to enable the hose to be fitted around other stationary items, or to allow vigorous and regular movement, for example when used with robotic applications.

For this reason, Eltherm apply a braided pressure relief construction tiered from one to three layers, ensuring that enough protection is provided for any given application, but also providing for a flexible and dependable means of scaling up the pressure withstand characteristics of the hose against a given specification.

This approach ensures that Eltherm hoses maintain strict design control from low pressure to high pressure applications, with all key parameters including thermal conductivity, durability and flexibility being optimised accordingly.

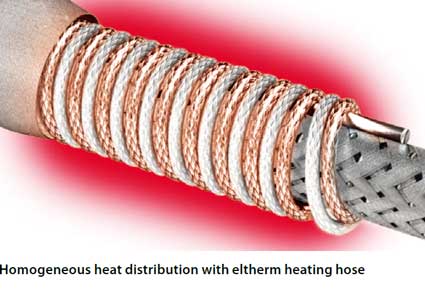

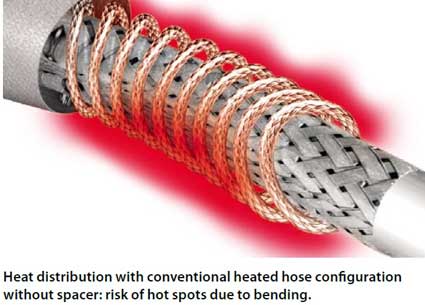

A further step taken is to spiral a spacer cord in a bifilar pattern along with the heating cable, ensuring that the heating cable can’t bunch up when the cable is flexed. This has two key benefits.

Firstly, the heating cable remains in place even while the heated hose is flexed, allowing for a uniform bend radius and reducing the risk of heating cable breakage.

Secondly, it avoids hot-spots occurring. Heated hoses may need to employ considerable heating power in order to maintain a given target temperature.

If the heating cables bunch together, this will result in an uneven heat distribution and worst still, if the heating cable spirals touch each other, this could result in the overheating or failure of the cable. The spacer cord eliminates this issue.

A range of thermal insulations are then applied over the traced hose, depending upon the specifics of the application.

Highly flexible fleece layers can be used indoors where a moisture free work environment can be assumed. Closed cell foam is an option for outdoor applications, or where the hose may come into contact with liquids.

The outer sheath or casing of the heated hose is also considered on an application specific basis.

A range of heated hose solutions are applied as standard, from nylon braiding, through to corrugated plastic (including anti-static options) and finally to stainless steel options. Cable exit and entry is also fully flexible and can be specified to fulfil even the most arduous of connectivity requirements.

Handling materials at elevated pressures and temperatures is an involved subject, but the provision of a highly engineered and tailored solution, presented in a plug-and-play format need not be.

With the fundamentals of the system requirements being understood upfront, Eltherm can produce an effective heated hose solution to almost any industrial application.

Further Reading

Flexible Heated Hoses For Analytic Gas Emission Applications

The Electrical Heating Package

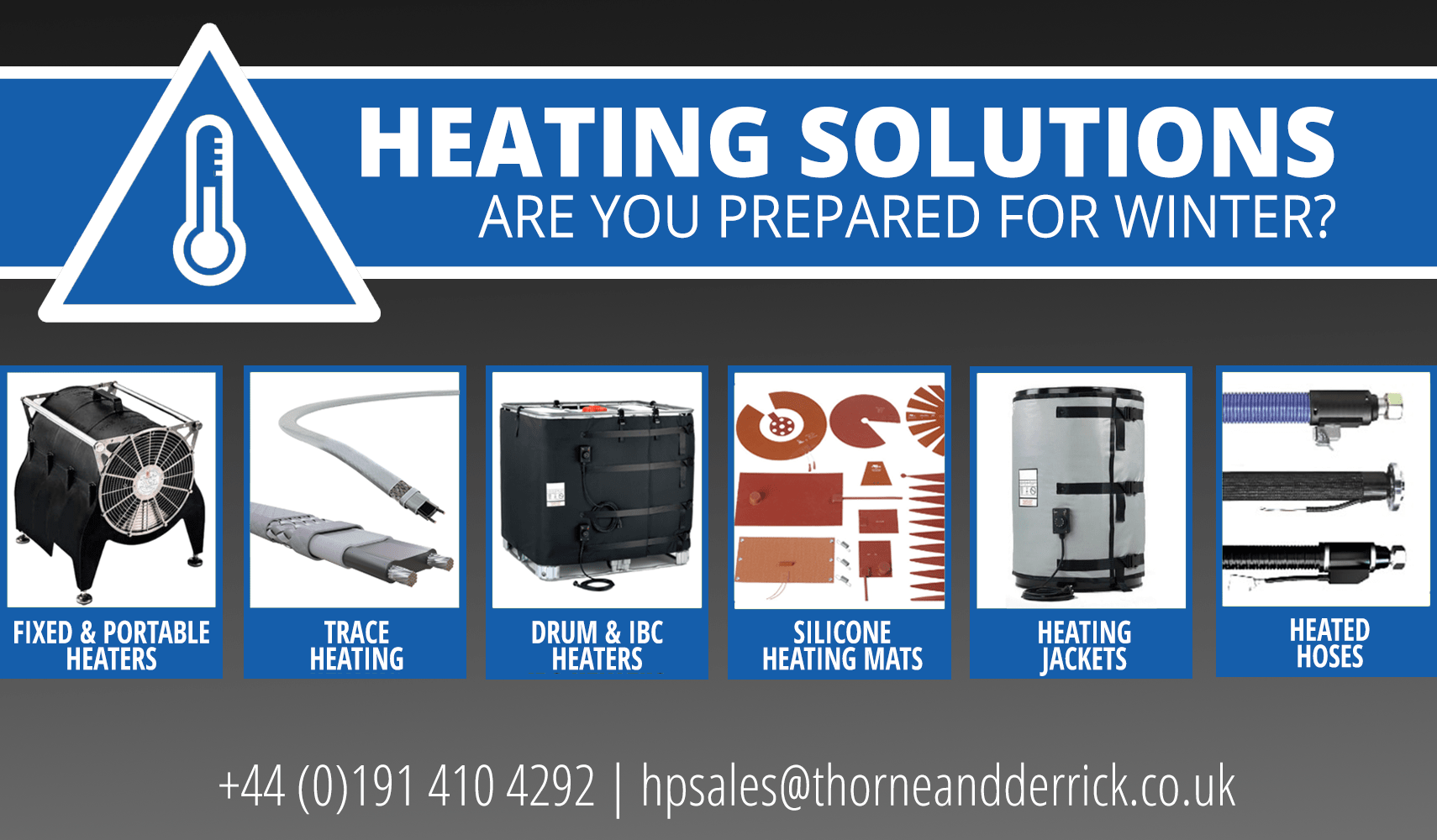

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial |Ramp Heating & Gutter Heating

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV