KROHNE Flow Meters | Custody Transfer Flow Measurement Of Hydrogen

Published 12 Jun 2020

Process Measurement Instruments – Flow, Temperature, Level & Pressure Measurement

KROHNE Flow Meters

Process Instrumentation for Industrial, Hazardous Area & Explosive Atmopheres

Ultrasonic Flow Measurement

KROHNE flowmeters and measurement instruments provide accurate and reliable measurement of industrial liquids, gases and other media (including emulsions, corrosive liquids and gases) with a range of low/high flow rates.

KROHNE is a world-leading manufacturer and supplier of solutions in industrial and explosive atmosphere process instrumentation – with over 30 worldwide approvals for hazardous area gas and dust Zones including ATEX, IECEx, usFMc, NEPSI, INMETRO, KGS, GOST-R and PESO/CCOE. The range of flowmeters manufactured by KROHNE incorporates multiple explosion proof and protection concepts – including IS (Intrinsically Safe) and Ex d (Flameproof) for flow measurement and metering in the hazardous area industries.

Flowmeters by KROHNE | the world-leading manufacturer and supplier of solutions in industrial and hazardous area process instrumentation: flow meters, level meters, temperature meters and pressure measurement.

Background

The Berre Petrochemical Cluster is a complex covering almost 1000 hectares located 30 km / 18.6 miles from Marseille, France, on the Étang de Berre lagoon. The site consists of a steam cracker as well as large-scale polypropylene and polyethylene plants.

The polyolefin plants produce polypropylene and polyethylene, the majority of which is used for consumer and industrial applications. Also located on the site are chemical plants and logistics facilities such as port facilities, pipelines, storage terminals and transhipment facilities.

Flow Measurement requirements

One of the producers requires the continuous flow measurement of hydrogen. The customer was looking for custody transfer flow measurement that would be in line with the internal procedure followed in compliance with the Sarbanes-Oxley Act (SOX).

The main objective of the act is to oblige the companies in question to develop and implement their own control procedures used to detect cases of fraud and/or errors in the financial management of the company. This ensures that the financial data disclosed by the company is both accurate and applicable, preventing false reports from influencing prices on the stock market.

It is important for the customer to accurately determine and invoice the hydrogen flow. The volume flow varies from 100…400 kg/h / 3.67…14.7 lb/min, the pressure from 9…15.7 bar / 130.5…227.6 psi and the temperature from 0…+20°C / +32…+68°F.

The producer required a pressure and temperature-compensated flow measurement (standard volume flow measurement) in custody transfer as per MID MI-002 and in accordance with the internal SOX procedure. To this end, the customer was looking for a reliable and accurate comprehensive flowmeter system that would comply with both the MID requirements and the company’s own procedures (accuracy, control, approval, documentation, certifications etc.).

These flow measurements allow the customer to invoice hydrogen consumption and guarantee income. Previously, the company had used an orifice plate (not MID compliant). The MID MI-002 approved equipment must also comply with ATEX Ex d.

KROHNE Solution

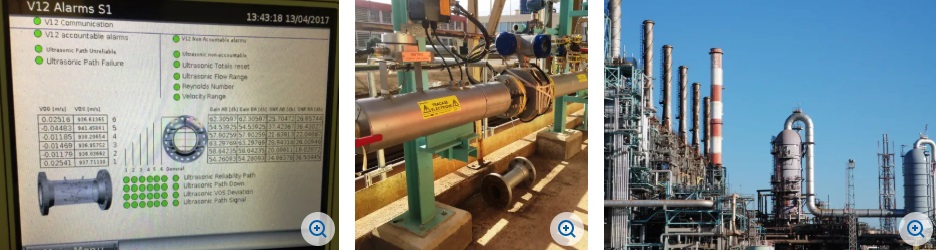

KROHNE provided a measuring system complete with the ALTOSONIC V12 ultrasonic gas flowmeter (DN 100, ASME Cl 300 flange) and the SUMMIT 8800 flow computer. The ultrasonic flowmeter was installed in a horizontal stainless steel pipe with straight inlet and outlet runs.

The measuring system complies with MID MI-002. In addition, KROHNE offered the “KROHNE Care” expert system, providing diagnostic functions for the ALTOSONIC V12 ultrasonic gas flowmeter.

Based on diagnostic parameters, this system interprets the functionality and accuracy of the measuring device around the clock. The 12-beam measuring device features a vertical diagnostic path that detects contamination on the bottom of the measuring tube.

KROHNE also offered to commission the system and train personnel in the use of the two measuring devices. The system had to feature integrated pressure and temperature sensors for custody transfer measurements. KROHNE prepared the documents for custody transfer including calibration certificates, MID certificates, technical documentation etc.

KROHNE Flowmeters

Customer benefits

The reliable and accurate measurement in accordance with MID is a clear benefit for the customer. The customer can now create invoices covered by MID approval that also comply with the internal SOX procedure.

Thanks to the “KROHNE Care” diagnostic system and the diagnostic path to detect contamination, this reliable and accurate measuring system featuring self-monitoring made process optimisation possible. As a result, production increased and the producer recorded increased revenue.

- Reliable and highly accurate measuring system

- Comprehensive solution in accordance with MID MI-002

- Self-monitoring of the measuring system for process optimisation

KROHNE Flowmeters Used

ALTOSONIC V12 Meter

Hazardous Area Process Instrumentation, Meters & Measurement – KROHNE ALTOSONIC V12

The ALTOSONIC V12 is a 12-chord ultrasonic custody transfer (CT) flowmeter for natural gas. It has been designed to offer the best possible measurement accuracy, not only during calibration under ideal conditions but also during less ideal conditions in the field. As a result, ALTOSONIC V12 is the first ultrasonic flowmeter that was certified to OIML R137 class 0.5 by NMi.

Due to its design with 12 acoustic chords a flow conditioner is no longer required; standards such as AGA9, ISO 17089 and MID are met with just 5D straight inlet piping. CBM flowmeter diagnostics are standard and give an exact picture of what is happening inside the flowmeter.

With the optional KROHNE Care diagnostic expert system an integrated web server becomes available that presents the results as an easy to access webpage – in plain language.

- Complete product family for widest application range

- 12 acoustic chords for excellent swirl immunity and built-in redundancy

- Dedicated diagnostic path for deposits, dirt or changes in surface roughness

- No flow conditioner required

- Just 5D straight inlet piping required to comply to AGA9, ISO 17089 and MID

- First ever ultrasonic flowmeter to receive OIML R137 class 0.5 approval by NMi

- Free of charge condition-based monitoring (CBM)

- Optional with KROHNE Care system for 24/7 evaluation of meter health and accuracy

Hazardous Area Process Instrumentation, Meters & Measurement – KROHNE SUMMIT 800

SUMMIT 880 Meter

The SUMMIT 8800 is a digital flow computer for custody transfer (CT) measurement. Its state of the art full colour graphical touch screen allows a graphical representation of the measurement process, with all measured values shown in real time; Up to 5 different types of meters combined in one flow computer, with CT measurements still being processed within 0.25s.

The SUMMIT 8800 communicates via digital, analogue, serial and Ethernet interfaces to obtain the measurement and diagnostics from the field converters and analysers. All calculated values (densities, flow rates, totals, etc.) are available in Modbus format which can be read by any PLC, SCADA, accounting system etc.

- Compliant with all main international standards, such as OIML, ISO, API, AGA, GOST

- Fully digital; no loss on accuracy due to analogue to digital conversions

- Enhanced diagnostics with logging of preselected measured parameters

- Modbus mapping & system compatibility (DCSs, PLCs, Supervisory, SCADA, HMI)

- Advanced system integration incl. eReporting push, web interfacing and remote monitoring

- Very short cycle time: down to 0.25 sec

- Redundant operation in duty-standby configuration

- Up to 8 non-CT multi product liquid applications per flow computer

Explosive Atmosphere Experts

Thorne & Derrick are Specialist Distributors of Hazardous Area Electrical, HVAC & Process Instrumentation Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

We supply major UK and international infrastructure projects and also MRO (Maintenance, Repair, Operations) requirements for both planned and unplanned plant shutdowns – we react with a rapid response to customer demand to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

We distribute Innovative products to manage the planned replacement of legacy equipment conformant with international classifications including ATEX and IECEx.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

➡ Also Process Instrumentation Products: Ashcroft Pressure Gauges | ASCO Valves | Katronic Flow Meters | KROHNE Flow Meters | VEGA Level Sensors | Rotronic Temperature & Humidity Sensors

Further Reading

-

KROHNE Flow Meters – Custody Transfer Flow Measurement Of Hydrogen – Application Report

Size: 249.36 KB

KROHNE Flow Meters – Custody Transfer Flow Measurement Of Hydrogen – Application Report

Size: 249.36 KB