Krohne Flowmeters | Custody Transfer Flow Measurement For (Un)loading Of LNG

Published 15 Jun 2020

Process Measurement Instruments – Flow, Temperature, Level & Pressure Measurement

KROHNE Flow Meters

Process Instrumentation for Industrial, Hazardous Area & Explosive Atmopheres

Ultrasonic Flow Measurement

KROHNE flowmeters and measurement instruments provide accurate and reliable measurement of industrial liquids, gases and other media (including emulsions, corrosive liquids and gases) with a range of low/high flow rates.

KROHNE is a world-leading manufacturer and supplier of solutions in industrial and explosive atmosphere process instrumentation – with over 30 worldwide approvals for hazardous area gas and dust Zones including ATEX, IECEx, usFMc, NEPSI, INMETRO, KGS, GOST-R and PESO/CCOE. The range of flowmeters manufactured by KROHNE incorporates multiple explosion proof and protection concepts – including IS (Intrinsically Safe) and Ex d (Flameproof) for flow measurement and metering in the hazardous area industries.

Flowmeters by KROHNE | the world-leading manufacturer and supplier of solutions in industrial and hazardous area process instrumentation: flow meters, level meters, temperature meters and pressure measurement.

Background

Cetil Dispensing Technology, S.L., located in Algete, Spain, is specialised in the field of fuel handling. The company produces among others fuel dispensers, systems for tank truck and loading racks as well as refuelling equipment.

The manufacture’s fuel dispenser portfolio ranges from CNG and LNG dispensers to dispensers for LPG, AdBlue® or multiproduct applications.

Flow Measurement requirements

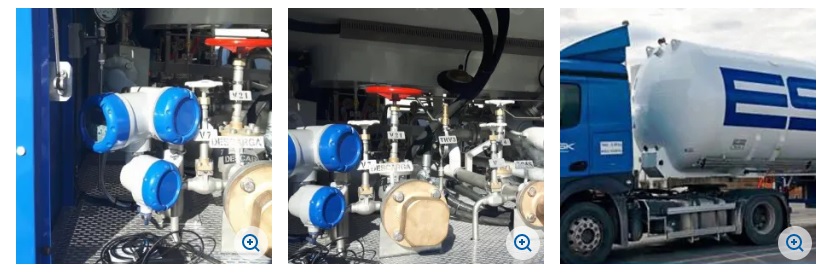

For ESK, a specialist company for the transport of dangerous goods, Cetil designed a dispensing system for loading and unloading of LNG (with a flow rate of up to 50,000 kg/h / 1837 lb / min). The dispenser was to be used for custody transfer (CT) operations on trucks.

LNG is a challenging product to measure. For loading, discharge, storage and transport it needs to be cooled down below its boiling temperature of -161.48 °C / -248 °F. Above that temperature the medium tends to evaporate, producing boil-off gas (BOG) that leads to gas entrainment.

This frequently occurs at the beginning of loading procedures when the pipeline used for transportation has a much higher temperature than the liquefied gas. As a rule, a certain amount of LNG has therefore to be fed through the line to cool it down to the extent that custody transfer operations can be carried out.

This is a costly and time-consuming procedure, involving significant product loss. Only if the pipeline is cooled down by the LNG, can the actual LNG measurement start.

Conventional Coriolis mass flowmeters have not been able to identify the point in time when the amount of BOG in the medium has significantly decreased so as to start with loading. They indeed switch to error mode whenever gas entrainments (vapour breakthrough) occur and have to be restarted.

The customer was therefore searching for an MI-005 approved flowmeter (in accordance with the Measurement Directive 2014/ 32/EU) that is also able to continue measurement in the event of two-phase flow. It was another measurement objective to optimise the loading process by identifying the vapour breakthrough.

Krohne Solution

KROHNE recommended using the OPTIMASS 6400 for the truck-mounted CT system. The Coriolis mass flowmeter with V-shaped measuring tube is designed for CT measurement in cryogenic applications down to -200 °C / -328 °F. The flowmeter was installed with a DN 50 stainless steel measuring tube and equipped with insulation casing.

Unlike conventional mass flowmeters the KROHNE device provides reliable readings even in the event of gas entrainment of up to 100 %. Using its Entrained Gas Management (EGM™) functionality, the OPTIMASS 6400 enables continuous and uninterrupted flow measurement, even if LNG contains a high amount of BOG. The device also provides the operator with a 2-phase-signal, indicating whenever BOG occurs in the process.

KROHNE Flowmeters

Customer benefits

The OPTIMASS 6400 does not only comply with the requirements of the MID MI-005. The customer also stands to gain from the Entrained Gas Management functionality of the Coriolis meter in the event of BOG.

The Coriolis meter continues to measure even during start-up phase when vapour breakthrough occurs. In using the meter’s 2-phase-signal, the customer is able to identify the best point in time to start with CT measurement. In this way, the EGMTM functionality helps with reducing the cooling time and enabling a faster loading / unloading process.

The start / stop procedure of the truck-mounted CT system can now be controlled by the 2-phase flow diagnostics of the OPTIMASS 6400. As a result, the operator can save on costs as product loss during cooling can be limited. This in turn allows the operator to better meet the production quality criteria in the end.

The high accuracy meter for LNG and BOG is just one of several KROHNE instruments used by CETIL in many different applications

- Equipping a dispensing system for cryogenic fuels with a Coriolis mass flowmeter

- Continuous measurement and indication of 2-phase-flow in the event of boil-off-gas (BOG)

- Improved control of loading procedure, cooling time and product quality

Further Reading

-

Krohne Flowmeters Custody Transfer Flow Measurement For (Un)loading Of LNG – Application Report

Size: 978.00 KB

Krohne Flowmeters Custody Transfer Flow Measurement For (Un)loading Of LNG – Application Report

Size: 978.00 KB