Krohne Flowmeters | Mass Flow Measurement Of Oil Products When Loading & Offloading Tank Lorries & Ships

Published 12 Jun 2020

Process Measurement Instruments – Flow, Temperature, Level & Pressure Measurement

KROHNE Flow Meters

Process Instrumentation for Industrial, Hazardous Area & Explosive Atmopheres

Ultrasonic Flow Measurement

KROHNE flowmeters and measurement instruments provide accurate and reliable measurement of industrial liquids, gases and other media (including emulsions, corrosive liquids and gases) with a range of low/high flow rates.

KROHNE is a world-leading manufacturer and supplier of solutions in industrial and explosive atmosphere process instrumentation – with over 30 worldwide approvals for hazardous area gas and dust Zones including ATEX, IECEx, usFMc, NEPSI, INMETRO, KGS, GOST-R and PESO/CCOE. The range of flowmeters manufactured by KROHNE incorporates multiple explosion proof and protection concepts – including IS (Intrinsically Safe) and Ex d (Flameproof) for flow measurement and metering in the hazardous area industries.

Flowmeters by KROHNE | the world-leading manufacturer and supplier of solutions in industrial and hazardous area process instrumentation: flow meters, level meters, temperature meters and pressure measurement.

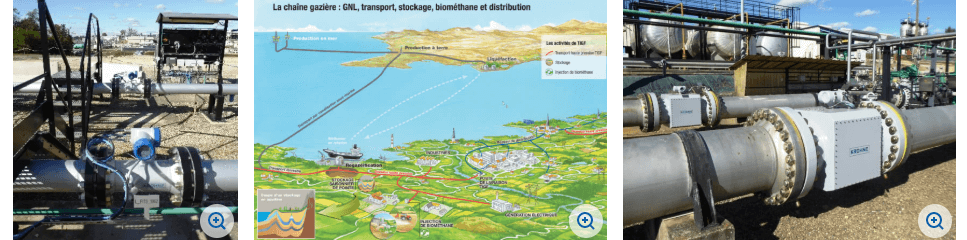

Background

SC Klaipedos Nafta is one of the largest oil ports on the Baltic coast in Lithuania. Crude oil and oil products are delivered by ships and freight trains and then loaded for further transport onto tank lorries and ships. Tank ships with a shipping volume of up to 100000 t can dock and the port capacity is 500 rail cars.

The storage volume is approx. 400000 m3. A new filling system suitable for custody transfer was necessary in order to increase the capacity for light oil products when loading tank lorries from tank cars.

Flow Measurement requirements

The new loading system for tank lorries had to be suitable for custody transfer and able to generate all financial data. Additional requirements included: simple installation, superior accuracy and smooth integration of the new system into the existing SCADA and filling control and control system. Measurements must be based on the European MID in accordance with MI-005 and API 5.5 Level A.

Product benzene E 95 ( = 95 % ethanol + 5 % benzene ):

- Density: 741…791 kg/m3

- Flow rate: 20…100 m3/h

- Viscosity: 0,45…1,5 mPa•s

- Operating pressure: 4 bar

- Operating temperature: -29…+35 °C/84.2…95 °F

KROHNE Solution

For this application KROHNE supplied 5 OPTIMASS 7300 C mass flowmeters and 2 SUMMIT 8800 digital flow computers. It is very easy to install the OPTIMASS measuring devices in the pipelines as there are no installation requirements.

Pipeline vibrations have no impact on the highly accurate measurements. The compact designs of the measuring devices make the electrical connection easier. The devices come equipped with density and temperature measurement as standard.

The devices can be started up and operated without any special knowledge. The SUMMIT 8800 is a digital flow computer featuring a large, easy-to-read colour display with multi-colour light control and touchscreen operation. The completely redundant Ethernet is suitable for WLAN when using all common protocols. The SUMMIT 8800 can be used for many different types of measurement.

KROHNE Flowmeters

Customer benefits

OPTIMASS mass flowmeters from KROHNE offer many advantages such as excellent long-term stability and repeatability, guaranteeing precise measuring results. The devices work extremely reliably. Because OPTIMASS 7300 C measuring devices can measure the mass flow directly, recalibration becomes unnecessary, even with varying process parameters. There is virtually no additional pressure loss due to the single straight measuring tube design of the mass flowmeters. This means that the required pump output is minimal.

- Equipping a loading system for tank lorries with Coriolis mass flowmeters

- Simple integration into existing SCADA, filling control and control system

- Custody transfer measurement in accordance with MID MI-005 and API 5.5 Level A

Further Reading

-

Krohne Flowmeters – Mass Flow Measurement Of Oil Products When Loading & Offloading Tank Lorries & Ships – Application Report

Size: 2.52 MB

Krohne Flowmeters – Mass Flow Measurement Of Oil Products When Loading & Offloading Tank Lorries & Ships – Application Report

Size: 2.52 MB