KROHNE Flowmeters | Measuring Seal Gas At Gas Seals In Turbo Compressors

Published 16 Jun 2020

Process Measurement Instruments – Flow, Temperature, Level & Pressure Measurement

KROHNE Flow Meters

Process Instrumentation for Industrial, Hazardous Area & Explosive Atmopheres

Ultrasonic Flow Measurement

KROHNE flowmeters and measurement instruments provide accurate and reliable measurement of industrial liquids, gases and other media (including emulsions, corrosive liquids and gases) with a range of low/high flow rates.

KROHNE is a world-leading manufacturer and supplier of solutions in industrial and explosive atmosphere process instrumentation – with over 30 worldwide approvals for hazardous area gas and dust Zones including ATEX, IECEx, usFMc, NEPSI, INMETRO, KGS, GOST-R and PESO/CCOE. The range of flowmeters manufactured by KROHNE incorporates multiple explosion proof and protection concepts – including IS (Intrinsically Safe) and Ex d (Flameproof) for flow measurement and metering in the hazardous area industries.

Flowmeters by KROHNE | the world-leading manufacturer and supplier of solutions in industrial and hazardous area process instrumentation: flow meters, level meters, temperature meters and pressure measurement.

Background

For a natural gas transportation project in Queensland, Australia, a leading international supplier of infrastructure solutions manufactures compressors for the compressor stations.

The compressors are designed to concentrate natural gas under pressure so that it can be transported. The manufacturer produces turn-key systems for this purpose, fits them with gas seals and equips the compressors with seal gas systems to seal the shafts.

Flow Measurement requirements

The function of the mechanical gas seals is to prevent the flammable natural gas from leaking out and to protect the compressors, which operate under significant pressures and high temperatures. Due to axial movement, the seals are subject to a high degree of wear and can fail, so they are equipped with seal gas systems.

These systems flush the seals with nitrogen to generate counterpressure. The objective of the measurement is to determine the amount of nitrogen used (3.0 to 30 kg / 6,6 to 66 lbs per hour) in order to ensure a continuous gas flow over the seals and monitor the amount of leakage.

In order to supply the compressors, the infrastructure specialist needs reliable flow measurement units to assemble such a seal gas system. Because ATEX approvals are no longer accepted in Australia, it was an absolute requirement that the devices be certified in accordance with IECEx-i. Moreover, it was required that all of the information can be transferred to a DCS via FOUNDATION™ fieldbus communication.

KROHNE Solution

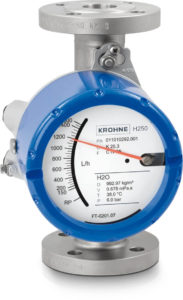

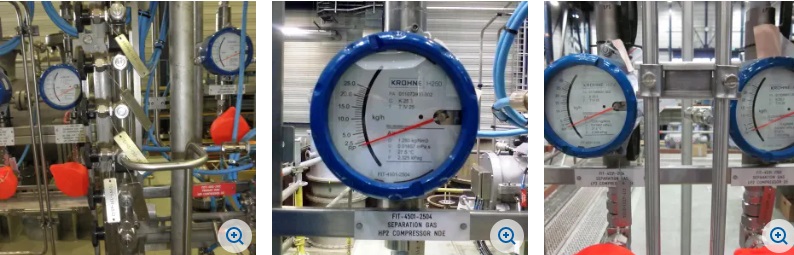

KROHNE manufactured over 300 units of the H250 M40 variable area flowmeter with a stainless steel cone, mechanical local display and a FOUNDATION™ fieldbus interface for the compressor manufacturer. The instruments have the required, intrinsically safe design in accordance with IECEx-i and the FISCO model. They were supplied with NPT process connection.

The customer performed the final assembly of the metering skids. The units were mounted onto a seal gas panel on a large frame next to the compressor. The H250 M40 devices measure the flow rate of the seal gas. The measuring results for the nitrogen can be transferred via 2-wire bus line in accordance with the FOUNDATION™ fieldbus standard.

With the H250 M40 devices, KROHNE met the customer’s extensive operational requirements, which included providing evidence of pressure tests and carrying out radiographic tests, among others, because many of the devices were supplied in the high pressure version.

KROHNE Flowmeters

Customer benefits

By equipping the seal gas panels with the H250 M40, the compressor specialist met a significant requirement for supplying his customer. This continuous nitrogen flow measurement enables leaks and defective seals to be recognized quickly. In this way, damage to the compressors can be prevented as early as possible.

Because the measuring instruments were supplied with screw process connections, the assembly time was shortened significantly and allowed a flexible, space-saving installation of the devices, in contrast to flange connections. The FOUNDATION™ fieldbus version design enabled direct integration into the end customer’s communication network without additional power supply or converters.

- Equipping seal gas panels for natural gas compressors

- Variable area flow measurement in accordance with the high safety requirements of IECEx-i

- Metering devices connected to a distributed control system (DCS) via FOUNDATION™ fieldbus

Further Reading

-

KROHNE Flowmeters Measuring Seal Gas At Gas Seals In Turbo Compressors – Application Report

Size: 2.29 MB

KROHNE Flowmeters Measuring Seal Gas At Gas Seals In Turbo Compressors – Application Report

Size: 2.29 MB