Custom Engineered Trace Heating Systems & Solutions For Power Stations By Eltherm

Published 08 Mar 2024

Custom Engineered Trace Heating Systems & Solutions

Power Station Trace Heating

Thorne & Derrick together with Eltherm UK are able to provide custom-engineered trace heating solutions and systems to power stations worldwide. This includes aiding with maintenance work and providing site health services to ensure each power station is operating effectively and efficiently. Together we are able to provide a maintenance, repair and operations programme offering a comprehensive range of trace heating products and electric control and monitoring equipment to global trace heating projects,

In an industrial setting, maintaining the efficiency and reliability of heat tracing systems is crucial for smooth operations, especially during critical periods like winter. Furthermore, Eltherm helps in recognising the significance of proactive maintenance to prevent downtime and ensure optimal performance.

Power station trace heating systems prevent freezing, maintain viscosity, and ensure product quality. However, without proper maintenance, they can become inefficient or fail, leading to costly downtime and potential safety hazards.

Benefits of Eltherm Power Station Heat Tracing Solutions:

- Prevention of Power Shutdowns: For instance, trace heating cables help prevent power shutdowns by maintaining critical equipment and infrastructure at optimal operating temperatures, especially during extreme weather conditions like freezing temperatures during the winter months.

- Ensured Maintenance: Trace heating cables provide continuous monitoring and maintenance of essential components such as pipes, valves, and instrumentation within the power station. This continuous heat maintenance prevents issues such as pipe freezing, which can lead to costly repairs and downtime.

- Enhanced Security: The constant monitoring and heating provided by trace heating cables contribute to the security of the power station infrastructure. So by ensuring that critical components remain functional and operational, trace heating cables reduce the risk of security breaches or failures due to equipment malfunctions.

TRACE HEATING SOLUTIONS

- Importance of Maintenance: Power stations operate under specific requirements to deliver a consistent and reliable electricity supply. Trace heating systems are integral components within these facilities, utilised for various applications such as frost protection, viscosity maintenance, and process temperature control.

- Tailored approach for Power Stations: Despite power stations having specific operational needs and regulatory criteria that must be followed. A large number of maintenance requirements can be addressed through assessments for power station operators, the development of bespoke maintenance plans, and the implementation of strategies that improve performance while guaranteeing industry compliance.

- Range of Maintenance Services: Eltherm’s maintenance services for powerstation trace heating systems encompass a comprehensive range of activities designed to maximise reliability and efficiency.

- Initial System Surveys and Assessments: Technicians conduct thorough system surveys and assessments to evaluate the condition and performance of trace heating components, including cables, control panels, and insulation.

- Cost Effectiveness and Risk Mitigation: Investing in proactive maintenance for power station trace heating systems offers significant cost-saving benefits in the long run.

- Site Visits and Customer Engagement: Site visits are essential to gain knowledge of operational challenges, system configurations, and maintenance requirements for power stations.

Thorne & Derrick specialise in providing specialist heating for industrial and hazardous areas including Eltherm’s heat tracing cables and heated hoses.

Value Added Service

As Eltherm UK Ltd’s Master Distributor of Heat Tracing Cables & Systems for the commercial, industrial, and hazardous area industries, Thorne & Derrick can deliver significant industry benefits and value-added service to you and your company. Our Strategic Partnership can help to maximise uptime and optimise revenue of your business.

Together. we have vast experience maintaining and upgrading heat tracing systems covering all applications and industries, and by listening to our customers’ requirements and concerns, we are able to offer a tailor-made approach that leads to system effectiveness. With the UK’s largest stock holding, we can supply trace heating solutions to quickly to keep you operational all year round.

Understanding the condition of the heat tracing system installed on site is vital. If any remedial work is required it can be planned and budgeted for in an organised manner, helping you to be cost effective and preventing unforeseen issues during critical winter months.

Overall, the utilisation of trace heating cables in power stations offers a comprehensive solution to address concerns related to power shutdown prevention, maintenance, and security, ultimately improving the reliability and resilience of the power plant operation.

Custom Engineered Trace Heating Systems and Solutions

The Electrical Heating Package

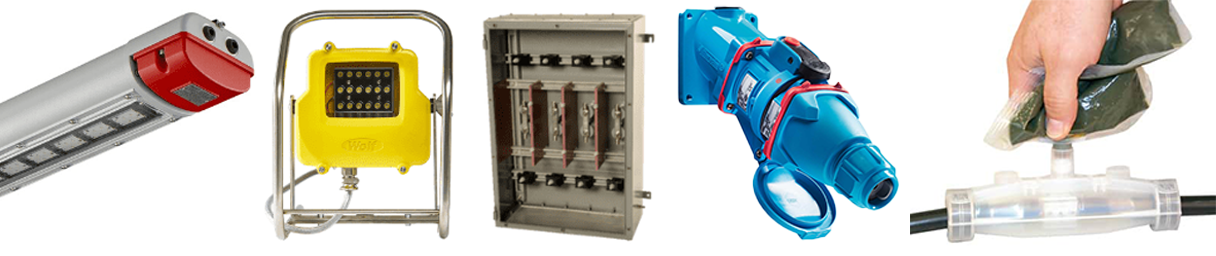

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial | Ramp Heating & Gutter Heating

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV