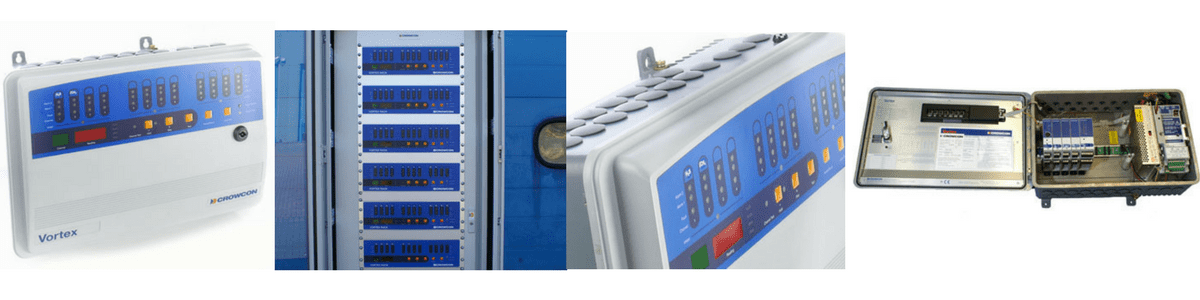

Crowcon Vortex Gas Detection Control Panel

Gas Detection Control Panels

Crowcon Vortex

Manufactured by Crowcon, the Vortex is a flexible control panel package which can be customised to meet your specific gas detection requirements without the need for extensive cabling.

Vortex Rack & Panel comprise just the essential input, output and controller modules mounted on a DIN rail while an optional display module is available in panel-mounting and 19″ Rack formats.

This configuration is ideal for incorporation into a variety of specialist enclosures, such as 19″ format or those with high ingress protection.

Other standard features include RS-485 Modbus communications for remote non-intrusive calibration and configuration.

Crowcon Vortex

Gas Detection Control Panel Features

- 1 to 12 channels (including 3 for fire) – up to 12 devices can be monitored by reviewing just one control panel, saving time and manpower

- Each channel has 1 fault level and 3 alarm levels which can be combined in any pattern to trigger up to 32 output relays – flexibility built in, initially configured to suit your operational needs, then channels/alarms are easily customised by you if requirements change

- Can be factory set to your requirements. Then when in situ, can easily be configured to suit your needs using Vortex PC software

- Push buttons on front display – day-to-day operations are easily undertaken

- LED display panel lights – faults are easily seen and whole system can be checked at a glance

- Modbus compatibility – no extensive cabling required; cable connections within the unit are easy

- Space within units for access to cable terminals

- Uses industry standard communication links – simple to integrate into existing control systems

- Any adjustments are performed electronically – minimal maintenance and no drift from adjustable potentiometers

- Separate zones can be individually inhibited – you can work on specific areas without affecting the rest of the system

- Modular construction – replacement parts if required, which plug straight in

- Validated to IEC 61508 (SIL 1) – demonstrates system dependability

- System monitors relays continuously – coil faults are identified immediately without input from you

- Internal battery pack* – power outs are not a problem. Internal battery pack continuously monitored for change levels and connection. System is operational at all times

*Not available on flameproof versions

Crowcon Vortex

Specification

| Crowcon Vortex Part Numbers | Vortex | Vortex Rack/Panel | ||

| Size | 470 x 306 x 170mm (18.5 x 12 x 6.5 ins) |

Rack display: standard 19” 3UPanel display: 441 x 128mm (cut-out 366 x 84.5mm)Modules, PSU and batteries are supplied separately for fitting within a cabinet. |

||

| Weight | 12Kg (27lbs) | Dependant on configuration | ||

| Enclosure material | Back-box: Aluminium Front cover: ABS |

Not applicable | ||

| Ingress protection | IP65 | Cabinet dependent | ||

| Channels | Up to 12 (1 to 3 4-way input modules) | |||

| Inputs | Gas | 2 or 3 wire 4-20mA (sink or source), 0-5V | ||

| Fire – smoke & heat detectors, manual call-points | Up to 3 loops, Up to 20 devices per loop | |||

| Outputs | External audible/visual alarm drive | Via relays, four 24Vdc 0.5A supplies provided. | ||

| Relays | Type | Up to 24 SPCO, contacts rated 6A @ 250Vac (1 to 3 8-way relay modules) |

Up to 32 SPCO with bus extension module | |

| Assignment – Common | Mains fail, battery low, battery fail | |||

| Assignment – Voting | Alarms, faults and system events | |||

| Relay modes | Energised/de-energised, latched/non-latched, time-delayed, pulsed | |||

| Digital communications | DCS/PLC/PC | RS-485 Modbus or Profibus | ||

| Local configuration link | RS-232 (configuration software and lead supplied) | |||

| Logging | Up to 300 alarm, power, fault, system events are stored in Non-Volatile Memory | |||

| Panel indication | Channel number | 2-digit 7-segment Green LED | ||

| Gas reading | 4-digit 7-segment Red LED | |||

| Measurement units | % LEL, ppm, % Vol, Fire | |||

| Power | Green LED | |||

| Battery OK | Green LED | |||

| Run/hold indication | Green LED | |||

| Channel test mode | Flashing Amber LED | |||

| System fault – integrity watchdog | Amber LED | |||

| Alarm indication | Audible – internal sounder | Piezo | ||

| Visual – Alarm | Level 1 & 2, Red LED | |||

| Visual – Fault | Per channel, Amber LED | |||

| Visual – Inhibit | Per zone, Amber LED | |||

| Power | AC mains | 110/120V & 220/240Vac (switchable) 50-60hz 3.2A max | ||

| DC | 20-30Vdc | |||

| Battery back-up | 2Ah internal | |||

| Approvals | Low voltage directive | EN61010-1 | ||

| EMC | EN50270, FCC, ICES | |||

| Hazardous area | Not applicable | |||

| Operating temperature | -10 to +40°C (14 to 104°F) | |||

| Humidity | 0-95% RH non-condensing | |||

| Functional safety | Validated to IEC61508 | |||

Crowcon Vortex 1-12 Channel Flexible Format Control System

Control Panels

Visit hazardous area gas detectors for explosion and flameproof gas monitoring and detection instruments with certification for potentially explosive atmospheres, including Zone 1 and Zone 2 (according to ATEX and IECEx) and Class/Division categories (according to North American standards).

T&D Sales Team are Certificated by Crowcon to support the specification and supply of their flammable and toxic gas detectors. Additionally, T&D are CompEx Certificated and competent in understanding hazardous area classifications and site requirements for the sale of explosion and flameproof equipment.

➡ More Crowcon: Portable Gas Detectors Fixed Gas Detectors