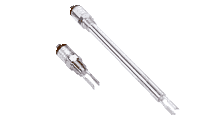

SICK LFV200 Level Sensors – Point Level Sensors

SICK SENSORS

SICK LFV200 Level Sensors – Point Level Sensors

- Housing made of 316L stainless steel

- Two electrical output versions available

- Commissioning without filling

- Process temperature up to 150 °C

- Immune to deposit formation

- Very high repeatability

- Aseptic versions with polished surface, CIP and SIP resistant

- Tube extension up to 1,200 mm

SICK LFV200 Level Sensors – BENEFITS

- Easy installation and commissioning, no pre-calibration necessary

- Easy operation and integration

- Maintenance-free system

- Sensors can be tested while installed

- Flexible, reliable system suitable for many types of applications

- Universal technology works in all kinds of liquids

- Economical solution for vertical mounting

- Can be used in containers and pipes regardless of installation conditions

SICK LFV200 level sensors are universal vibrating level switches precisely detects predefined liquid levels in systems to the millimeter. The switches can emit a signal to prevent overfilling, a switching signal for refilling, or a dry-run signal for pump protection.

The LFV200 works independently of the liquid and is wear-free and maintenance-free. The rugged stainless steel tuning fork is piezo-electrically energized and vibrates at its resonance frequency. Once the tuning fork is covered with liquid, the resonance frequency changes. This change is detected and converted into a switching signal.

A high-quality stainless steel surface in combination with aseptic process connectors make the Sick LFV200 the level sensor of choice in applications with stringent hygiene requirements. Thanks to its compact size, the LFV200 can be mounted even in areas that are difficult to access. The LFV230 product family also includes tube-extended variants for vertical mounting.

SICK Level Sensors – Continuous Level Measurement & Point Level Measurement

SICK LFV200 Level Sensor – TECHNICAL DATA

| Measurement principle: | Vibrating Level Switch |

| Detection principle: | Contact |

| Medium: | Fluids |

| Measurement: | Switch |

| Process temperature: | –40 °C … +150 °C |

| Process pressure: | –1 bar … 64 bar |

| Output signal: | Non-contact switch / 1 x PNP |

| Accuracy of sensor element: | ± 2 mm |

LIQUID LEVEL SENSOR APPLICATIONS

SICK LFV200 Level Sensors enables both continuous level measurement and point level measurement of liquids in metal containers, tanks and vessels – this includes liquids that foam or film.

Discontinuous level measurement in storage tanks

Point level measurement in storage tanks provides overfill protection, an empty signal, and dry-run protection for pumps, to name just a few examples.

With its wear-resistant and maintenance-free functionality, not to mention its ability to be used in all kinds of liquids, the LFV200 vibrating level switch is clearly the ideal choice for this type of application. Its hygienic design includes a high-quality housing finish and aseptic process connections.

➡ Did you know? T&D Hazardous Area team are trained and certified in the specification and sale of flameproof and explosion-proof equipment, including Crowcon Gas Detectors.