URBAN Linear | Transforming Working Conditions | RAYTEC Case Study

Published 06 Nov 2023

Transforming working conditions

The existing installation Raytec predominantly used 2x58W T8 fluorescent fittings, mounted 4.1m above the factory floor, combined with emergency twin spot style fittings to provide backup illumination in the event of mains power being lost.

With many of the old fluorescent tubes degrading and beginning to ‘yellow’, frequent maintenance and relamping had been required to keep the illumination to an acceptable level. Despite this ongoing maintenance, illumination uniformity was poor with several dark spots around the factory floor. As a result, there was a need for additional task lighting at bench level to assist the operators.

Outcome of using URBAN Linear Lighting

However with the supply of fluorescent tubes being banned from September 2023, the need to upgrade the lighting system to LED technology was more pressing than ever.

Additionally another issue was the layout of the luminaires. Having been first installed by a previous occupier of the building, the luminaires did not align with the racking located at one side of the factory floor which is used to store parts used by operators during production. So this meant illumination between the racking was below the desired levels and also caused an obstruction which limited the height of the racking.

WL84 Generation Linear

These SPZ-WL84 Light fittings are globally certified to Zone 2 offering long life LED Technology.

This range is manufactured by Raytec and distributed by Thorne and Derrick and are designed for new hazardous area installations or to retrofit existing fluorescent installations which require high performance, high reliability and white light illumination in potentially explosive atmospheres.

Secondly, Raytec’s URBAN Linear luminaires are specifically designed for Industrial applications, were used to replace the existing fluorescent fittings on a 1-for-1 basis. While the new installation used the same number of fittings, the more powerful URBAN luminaires meant smaller, more efficient units could be installed in place of the larger 2x58W (5ft) fluorescents.

A mix of URBAN Linear WL84 (36W, 2ft) and WL168 (72W, 4ft) luminaires were deployed across the installation.

In conclusion, the URBAN LED luminaires significantly improved the quality of illumination, increasing average lux levels from 300lx to 400lx with improved uniformity. The extent of the upgrade means the reliance on task lighting is significantly reduced.

Key Benefits of using Spartan URBAN Linear

- More Efficient units

- Increased Lux levels 300lx to 400lx with improved uniformity

- Consumption reduced

- Daylight Harvesting

Further Reading

- Hazardous Area Lighting | SPARTAN Street Ex Luminaire By Raytec

- Fluorescent Lamp Ban | Plan For A Brighter Future With Thorne & Derrick & Raytec

- Raytec SPARTAN Flood & Bulkhead | The Lighting Evolution

More case studies

- Heated Pressure Hoses | Flexible Pressure Hoses | Eltherm

- AMS Equipment | Making Dangerous Work Safer | Crowcon Case Study

- Ramp & Stair Heating | Open space heating Systems | Eltherm

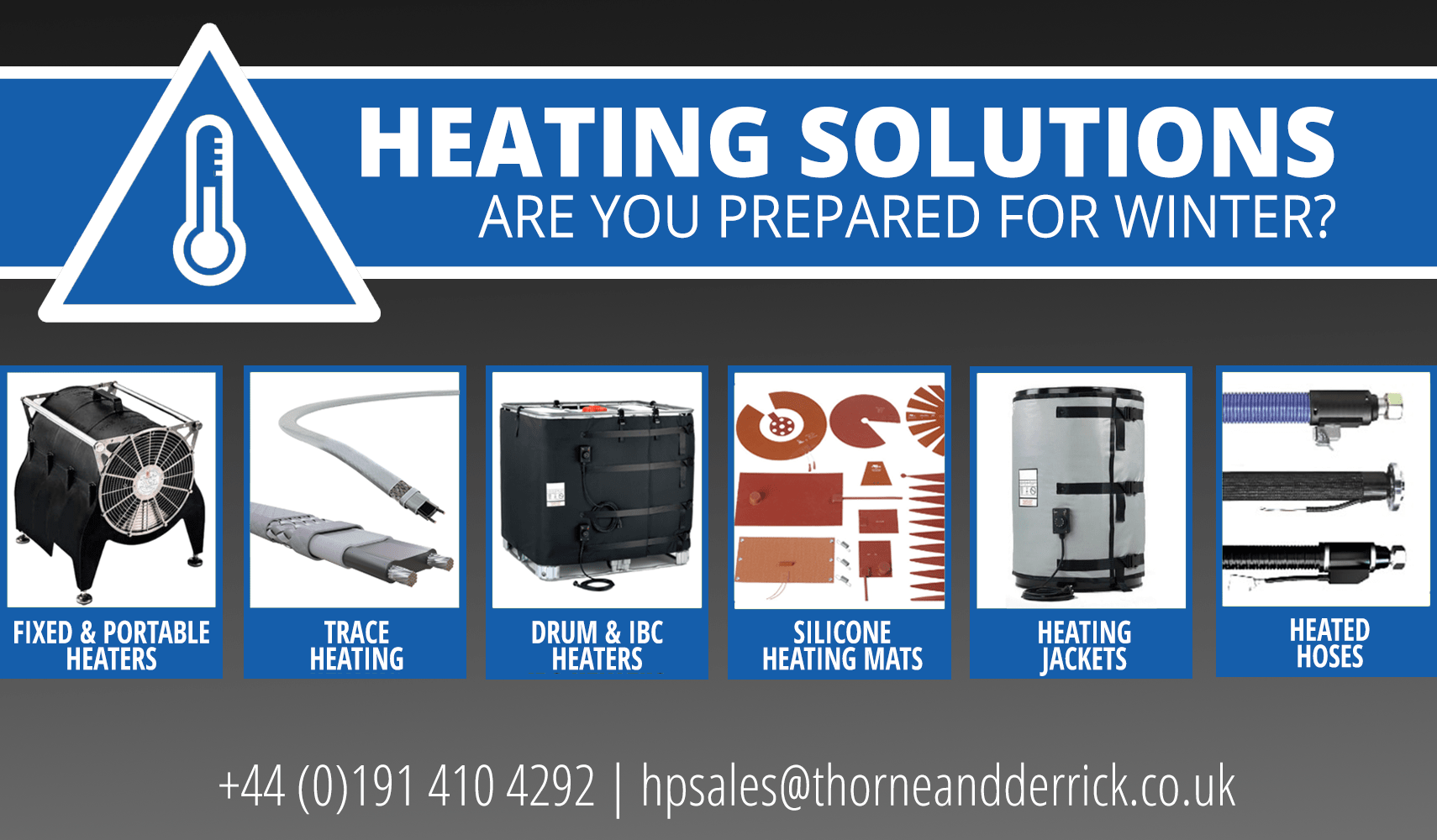

The Electrical Heating Package

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial | Snow Melting & Ice Clearance for Ramps & Roof Gutters

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV

Further Reading

-

Raytec ATEX Light Fittings SPARTAN Zone 2 SPZ-WL84

Size: 498.22 KB

Raytec ATEX Light Fittings SPARTAN Zone 2 SPZ-WL84

Size: 498.22 KB