Pepperl + Fuchs – FREE Explosion Protection (ATEX) & Functional Safety (SIL) Training Seminars

Published 17 Oct 2016

Explosion Protection (ATEX) & Functional Safety (SIL) Training Seminar By Pepperl + Fuchs, The Process Automation Specialists

- By Chris Dodds : estimated reading time 3 minutes

Thorne & Derrick, The Explosive Atmosphere Experts, have registered to attend the latest Pepperl + Fuchs training seminar – as specialist  distributors of Electrical, Mechanical, Process & Instrumentation Equipment to the hazardous area industries our Sales Engineers are committed to providing the highest levels of customer service.

distributors of Electrical, Mechanical, Process & Instrumentation Equipment to the hazardous area industries our Sales Engineers are committed to providing the highest levels of customer service.

We deliver this commitment through a thorough understanding of hazardous area classifications, explosion protection methods, legislation compliance and the relationships between electrical equipment, gas groups and temperature classes.

We recommend our clients, suppliers and supporters consider registering their attendance to this excellent “up-skilling” opportunity provided by Pepperl + Fuchs, The Process Automation Specialists.

Pepperl+Fuchs Explosion Protection Equipment

EXPLOSION PROTECTION

Process Automation

FREE Two ONE day Explosion Protection training seminars – 9am-5pm

- 8th November 2016 – Barton-upon-Humber

ATEX

- 10th November 2016 – Oldham

Seminar Itinerary

1. Physical Basics

- Ignition characteristics of combustible substances (ignition temperature, explosion limits, flash point etc.)

- Potential sources of ignition

2. Legal Basics

- Differentiation between placing on the market (94/9/EC) and putting into service (1999/92/EC)

- Manufacturer’s responsibility (marking, certification, documentation)

- User’s responsibility (zone classification, explosion protection document, examination)

3. Types of Protection – Gas

- Functional principles (Ex e, Ex d, Ex i)

- Extended (technical) marking

- Typical installation errors

- New: equipment protection level EPL

4. Intrinsic Safety

- Present state of standardisation

- Functional principle

- Verification of intrinsic safety (50%-rule)

- Comparison between ic and nL

- Installation requirements (e.g. cables, terminals, earthing, shielding etc.)

5. Dust Explosion Protection

- particularities of combustible dusts

- type of protection “t”: functional principle and marking

- consideration of the safety margins

SIL – EN 61508 & 61511

FREE Three ONE day SIL training seminars – 9am – 5pm

- 7th November 2016 – Teesside

- 9th November 2016 – Barton-upon-Humber

- 11th November 2016 – Oldham (9am – 4.15pm)

SEMINAR ITINERARY

1. Introduction

- scope of EN 61508 and 61511

- terms and definitions (risk, SIL, systematic and random failures, common misunderstandings with respect to SIL)

2. Risk Analysis

- determination of basic risk and tolerable risk, quantification, minimum endogenous mortality

3. Failure performance of equipment

- lifetime, MTBF, MTTR etc.; failure rates, difference between process technology and mechanical engineering, difference between electrical and mechanical equipment, Weibull-distribution

4. Avoidance of (systematic) failures

- Functional Safety Management System, failure prevention and failure control, hardware fault tolerance, safety life cycle, documentation

5. Control of (unavoidable (?) and random)) failures

- diverse and homogeneous redundancy, safe failure fraction SFF, diagnostic coverage DC, calculation of random failures

6. Proven in use

- proven in use assessment according to NE 130 (German proposal)

7. Implementation of protective equipment

- failure control acc. To EN 61511 – probability of failure on demand acc. To EN 61508

Please see the booking form PDF attached below.

BOOKING FORM – Complete for ALL seminars

We have curated a collection of our favourite Pepperl + Fuchs #AUTOMATION tweets – for more go to Twitter and Follow @PepperlFuchs

Pepperl + Fuchs

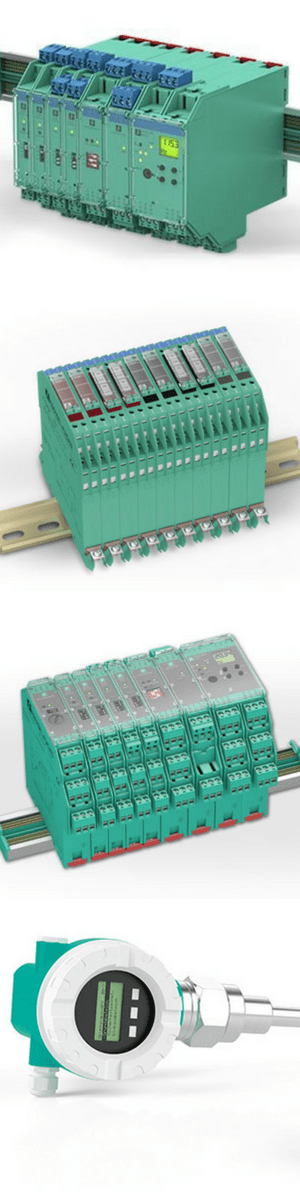

Process Automation & Electrical Equipment Product Range

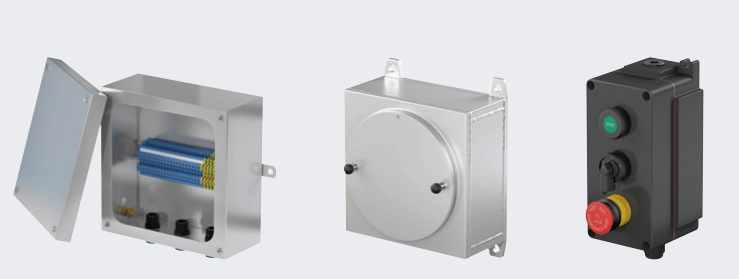

Pepperl+Fuchs are leading suppliers of automation equipment for hazardous areas and process automation industries – the Pepperl + Fuchs product ranges includes intrinsic safety isolators, Zener barriers, signal conditioners, fieldbus technology, Remote I/O, HART interfaces, level measurement, purge and pressurization systems, Human Machine Interfaces (HMI) for hazardous environments, custom cabinets, and junction boxes.

Explosion Proof Electrical Enclosures & Control Stations – Ex e, Ex ia, Ex e Hazardous Areas

Invitation – network, engage, promote

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group – Process & Hazardous Area Industries : Heat Tracing, Gas Detection, Fluid Control & Flow Measurement. News, projects, videos, promotions, whitepapers, jobs, webinars, press plus much more.

Further Reading

-

Pepperl + Fuchs Training Seminar Booking Form

Size: 89.34 KB

Pepperl + Fuchs Training Seminar Booking Form

Size: 89.34 KB

-

Pepperl + Fuchs Process Automation – Explosion Proof, Hazardous Areas & Industrial

Size: 3.32 MB

Pepperl + Fuchs Process Automation – Explosion Proof, Hazardous Areas & Industrial

Size: 3.32 MB