The Importance of Grounding of Intrinsically Safe Devices in Hazardous Areas

Published 29 May 2020

The Importance of Grounding of Intrinsically Safe Devices in hazardous areas.

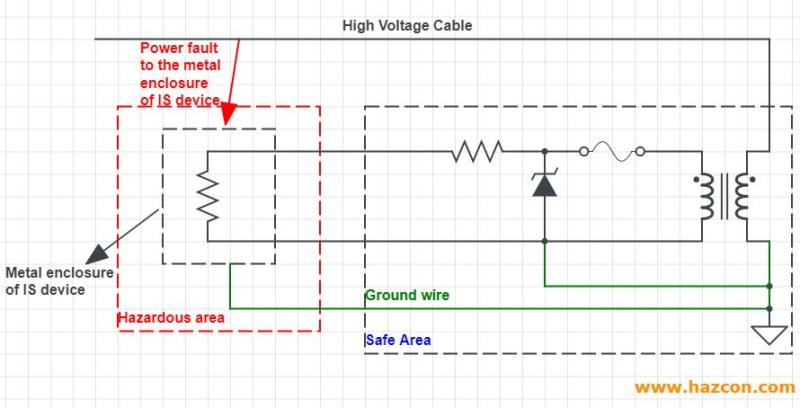

Intrinsic safety is system concept and it prevents explosion in hazardous areas by limiting electrical energy. The IS device which is installed in a classified area needs to be connected to a source of power (IS barrier) by cabling. Therefore, possible faults within the power system and cabling need to be considered.

When faults occur within safe area, the ground (earth) wire connected to the barrier busbar will provide a return path to the main earth mat or neutral star point of the distribution transformer.

But how about when power faults occur within the hazardous area and cause the power voltage to be appeared on the metal enclosure of the IS device?

A grounding facility is required for all electrical equipment with metal enclosures (including IS devices) to divert large fault current into a low-impedance return path and preventing high voltage being generated in hazardous area.

Per Article 504.50 of NFPA70 and Rule 18-072 of CEC: “Intrinsically Safe apparatus with metal enclosure shall be connected to equipment grounding conductor”.

Information Courtesy

Author Behzad Nejad, P. Eng. (Hazcon)

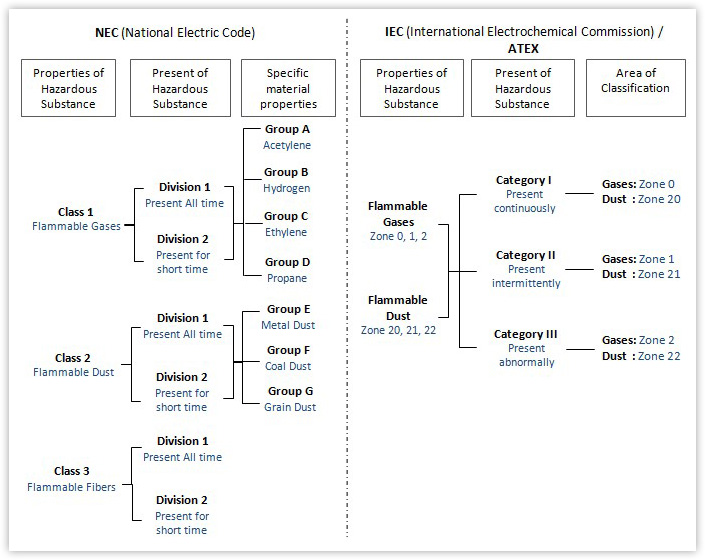

Director & Consulting Engineer at Hazcon Inc.; Hazardous Locations Consulting Services; IECEx, ATEX, CEC & NEC

Specializing in the design, safety and approval of electrical equipment for hazardous locations.

Mr. Nejad has over 15 years of experience as an Electrical Engineer and is a sought after professional in the hzardous area and explosion protection industry. He is fully-qualified at the advanced level of all hazardous locations protection techniques including Intrinsic Safety & Non-incendive, Explosion Proof & Flame proof, Increased Safety, Non-arcing, Purging and Pressurization, Encapsulation, Optical Radiation, and Dust-tight enclosures. Mr. Nejad’s tenure in the industry includes six years at the CSA certification agency, working closely with manufacturers (Emerson, GE, ABB, Siemens, Endress-Houser, VEGA etc.) as a technical and certification engineer for Hazardous locations equipment.

The opinions expressed in this article are those of the author.

Hazloc Products with Class 1/Division 2 & ATEX Certifications

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery