Class I Division 1 Products & Hazardous Area Locations

Published 29 May 2020

“Class I, Division 1” Electrical Rotating Machines

Electrical machines with “Class I, Division 1” marking are based on “explosion-proof” design. In order to get “C1D1” marking, there are two steps:

1) Ordinary location requirement per standards CSA C22.2 No. 100 for Canada and UL 1004 for the USA. These standards covers general safety aspects (i.e. electrical shock, fire hazard, etc.).

2) Hazardous location requirement per harmonized standard CSA C22.2 No. 145 & UL 674 for Canada and the USA.

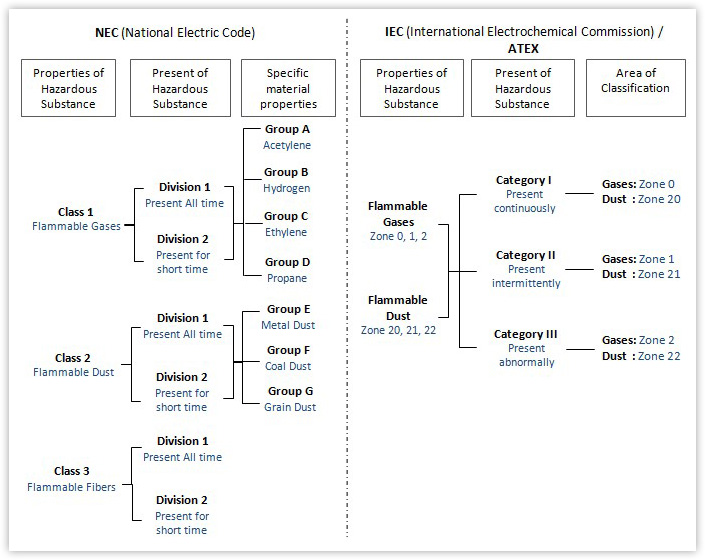

This standard uses “Explosion Proof” technique for electric motors and generators or submersible and nonsubmersible sewage pumps for Class I, Division 1, Groups B, C, D.

Notes:

i.) Hazloc electrical machines can NOT be certified for gas group A (Acetylene – IIC). The only solution is using purging technique with a clean air or inert gas when Acetylene is present.

ii.) IECEx certifications or Zone system protection techniques can NOT be used to get “C1D1” marking for electrical machines.

iii.) “C1D1” marking for electrical machines can be obtained by one of NRTLs only.

Information Courtesy

Author Behzad Nejad, P. Eng. (Hazcon)

Director & Consulting Engineer at Hazcon Inc.; Hazardous Locations Consulting Services; IECEx, ATEX, CEC & NEC

Specializing in the design, safety and approval of electrical equipment for hazardous locations.

Mr. Nejad has over 15 years of experience as an Electrical Engineer and is a sought after professional in the hzardous area and explosion protection industry. He is fully-qualified at the advanced level of all hazardous locations protection techniques including Intrinsic Safety & Non-incendive, Explosion Proof & Flame proof, Increased Safety, Non-arcing, Purging and Pressurization, Encapsulation, Optical Radiation, and Dust-tight enclosures. Mr. Nejad’s tenure in the industry includes six years at the CSA certification agency, working closely with manufacturers (Emerson, GE, ABB, Siemens, Endress-Houser, VEGA etc.) as a technical and certification engineer for Hazardous locations equipment.

The opinions expressed in this article are those of the author.

Hazloc Products with Class 1/Division 2 & ATEX Certifications

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery