Keep On Track & On Time With Eltherm Rail Heat Tracing Solutions

Published 20 Oct 2023

Rail Heat Tracing

Frost Protection

Rail traffic has to run smoothly even in cold and snowy winters. With rail transport it is not only about getting a lot of people to their destinations on time but also ensuring passengers safety.

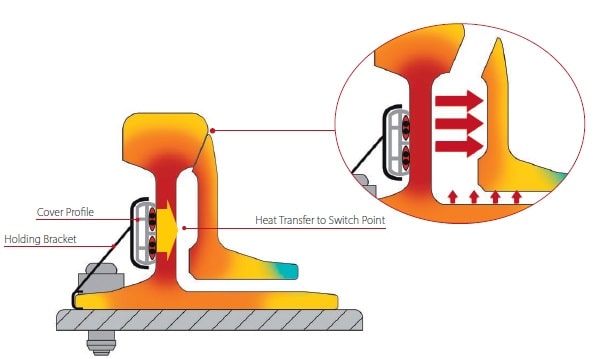

Freeze prevention on tracks and switch points is imperative to keep them free from ice so trains can safely operate on track and on time. A reliable, energy efficient electrical trace heating system with intelligent control achieves just that as well as providing several technical and economic advantages such as:

Electrical Trace Heating System Benefits

- Optimised heat transfer from the trace heater to the railway track or switch point

- Best possible energy efficiency and cost saving operations

- Simple, fast assembly for quick installation and easy maintenance

- Low maintenance effort

- Prevention of damages or short-circuits through moisture thanks to fluoropolymer insulation

- Easy access to the trace heater thanks to attachment to the outside of the rail or switch point

- Protection and prevention of heat loss thanks to thermally insulating cover profile

Thorne & Derrick, the UK’s leading Specialist Distributor of Electrical Process & Trace Heating Solutions, earlier this year announced they have entered into a Strategic Partnership with Eltherm UK Ltd, the subsidiary of the Eltherm Group, a world-class manufacturer of Heat Tracing Cables & Systems for the commercial, industrial and hazardous area industries.

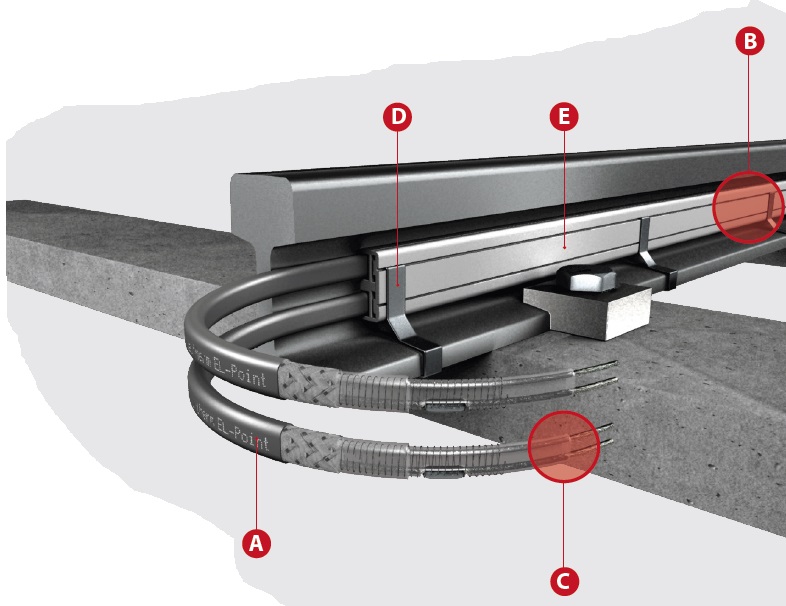

Example of a switch point heating being tested in Burbach, Germany

Rail,Track and Switch Point Heating Checklist

A Trace Heating

B Power connection

C Termination

D Holding bracket

E Cover profile

F Switch lock heating (not shown)

The checklist is a schematic illustration of rail, track and switch point heating. This is just a schematic overview, not an installation instruction. For detailed information, please contact T&D.

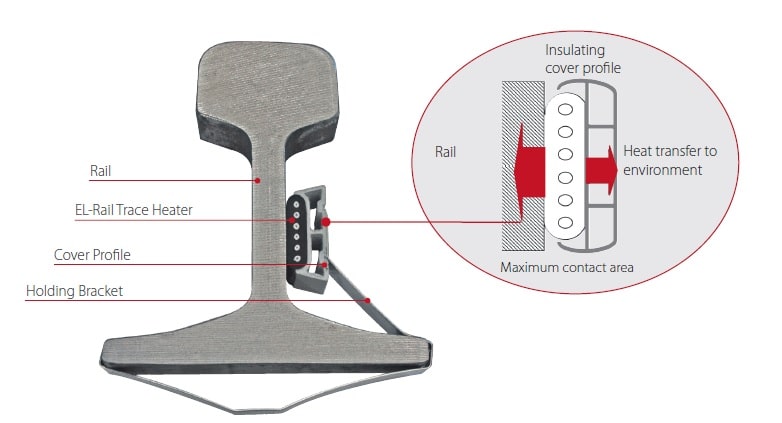

EL-Rail

up to 150ºC

The eltherm EL-Rail is a flat cable, combining six Fluoropolymer insulated series heating conductors in a silicone over-jacket. Superior properties of the heating system include: low installation and operation costs with professional support from eltherm making the EL-Rail the first choice in rail heating applications.

Technical Information

| Max. maintain temperature | 50 °C |

| Max. exposure temperature (de-energised) | 150 °C |

| Maximum nominal voltage | 1000 V |

| Minimum bending radius | 2“ / 50 mm |

| Power output | 50 – 150 W/m |

| Dimensions | 8 x 34 mm |

| Minimum installation temperature | – 40 °C |

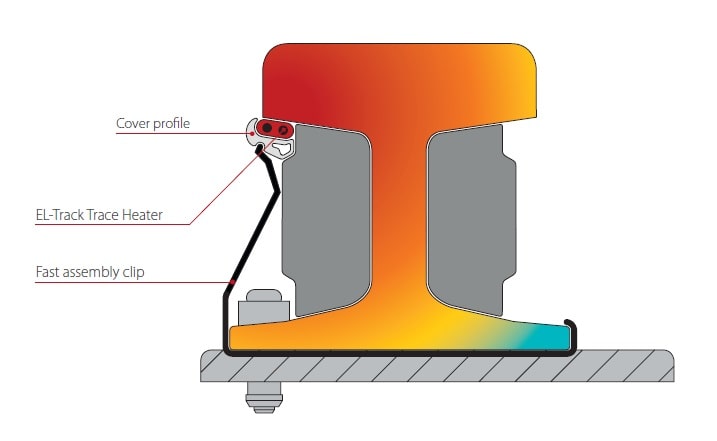

EL-Track

up to 200 °C

EL-Track is a parallel resistance trace heater with constant wattage (W/m) power output, fluoropolymer insulation and thermally insulating cover profile and fast assembly clip for freeze prevention on power rails. Installation occurs directly under the head of the rail instead of on the neck and ensures high heat transfer directly to the top of the power rail. Fast installation on long tracks thanks to innovative fast assembly clip.

Technical Information

| Max. maintain temperature | 50 °C |

| Max. exposure temperature (de-energised) | 200 °C |

| Maximum nominal voltage | 750 V |

| Minimum bending radius | 2“ / 50 mm |

| Power output | 50 – 150 W/m |

| Dimensions | 15 x 7 mm |

| Minimum installation temperature | – 50 °C |

EL-Point

up to 200 °C

With the EL-Point heating cable, eltherm has developed a particularly efficient and intelligent solution. Compared to conventional flat rod heating elements, our flexible trace heating systems offer network operators technical, economical and logistical advantages. By means of the versatile adaptability, any unevenness is compensated. This enables a better heat transfer from the heating cable to the rail. As a result: The rail temperature increases at comparatively lower power output.

Technical Information

| Max. maintain temperature | 50 °C |

| Max. exposure temperature (de-energised) | 200 °C |

| Maximum nominal voltage | 750 V |

| Minimum bending radius | 2“ / 50 mm |

| Power output | 50 – 150 W/m |

| Dimensions | 15 x 7 mm |

| Minimum installation temperature | – 50 °C |

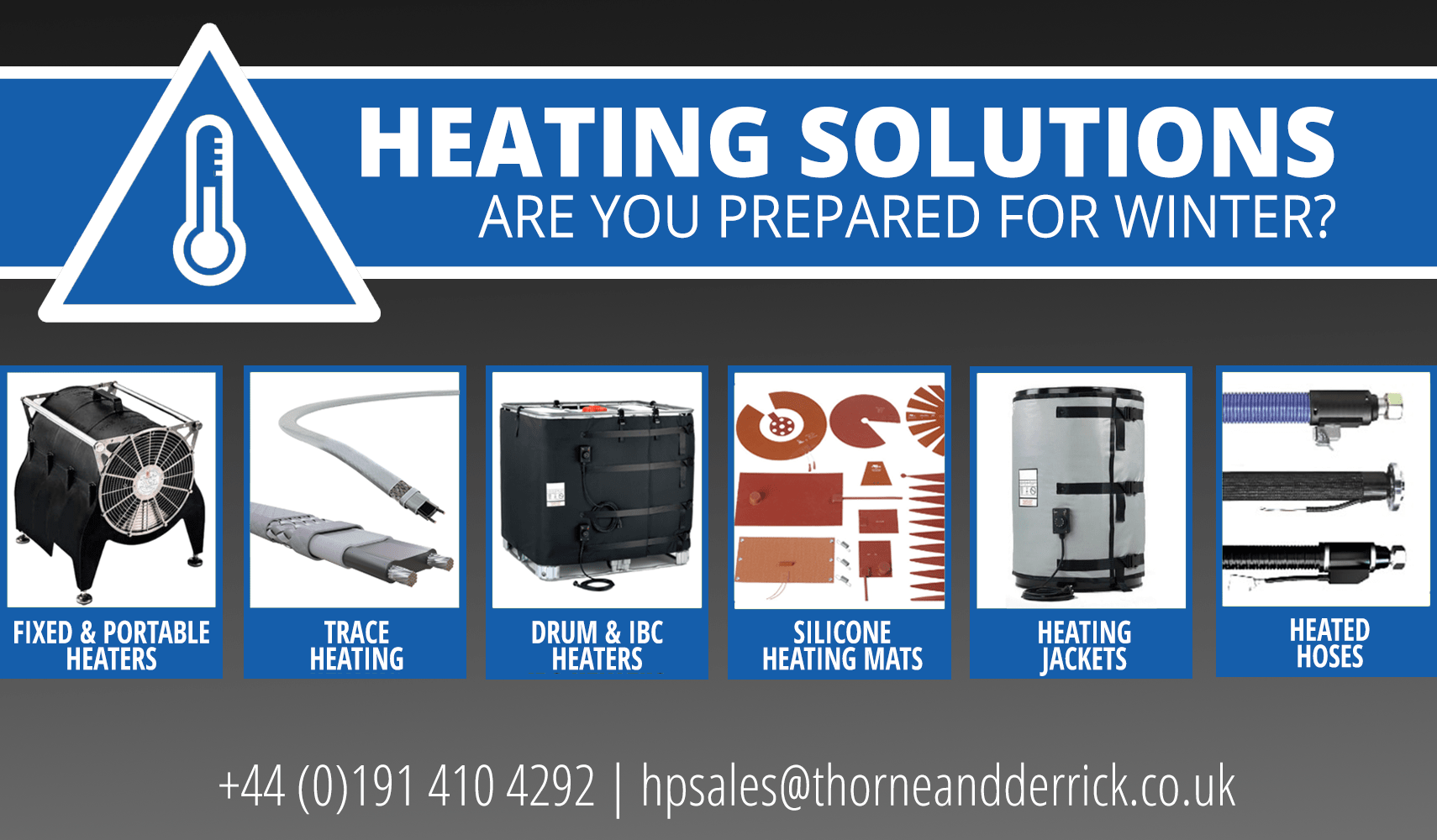

The Electrical Heating Package

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial |Ramp Heating & Gutter Heating

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV

Further Reading

-

Rail, Track and Switch Point Heating – Brochure

Size: 5.57 MB

Rail, Track and Switch Point Heating – Brochure

Size: 5.57 MB