Electrical Trace Heating Solutions For The Chocolate Industry

Published 09 Mar 2024

Electrical Trace Heating Solutions For The Chocolate Industry

Trace Heating Solutions

Temperature Maintenance for chocolate production

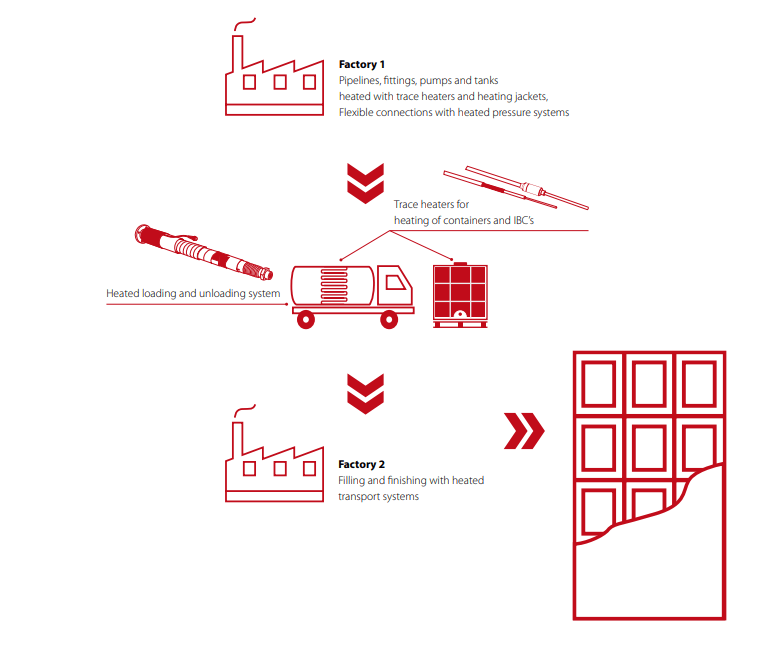

Keeping the perfect temperature is not just a matter of taste but a crucial element that defines the quality of the end product. The journey from raw cocoa to the silky-smooth chocolate bar requires temperature control, and this is where electrical heat tracing (EHT) systems step in.

Importance of Temperature Control: Chocolate is a delicate creation that demands precise temperature control throughout its production process. Any fluctuation in temperature can lead to undesirable outcomes such as crystallisation, texture variations, or compromised taste. To ensure the chocolate flows seamlessly through every stage of production, from pipes to dosing machines, a constant and fluidic state is paramount.

Role of Electrical Heat Tracing Systems: Electrical heat tracing systems play a pivotal role in maintaining the optimal temperature required for chocolate production. These systems are responsible for ensuring that the chocolate remains fluid and consistent as it moves through various stages, including pipes, valves, pumps, vessels, silos, processing plants, extraction points, dosing, and filling machines.

Single-Source Solution: Choosing the right partner for implementing electrical heat tracing systems is crucial for the chocolate industry. Eltherm stands out as a reliable single-source solution for the engineering, planning, installation, and commissioning of complete EHT systems. What sets Eltherm apart is its in-house engineering and production facilities for EHT products and systems.

Reliability and Uninterrupted Performance: The integration of Eltherm’s EHT systems ensures a seamless chain of heating performance, guaranteeing the chocolate’s uninterrupted flow and consistency. The reliability of these systems is crucial in avoiding downtimes in production, as any interruption can lead to not only financial losses but also a compromise in the quality of the final product.

Benefits of Eltherm’s EHT Solutions:

- Precision Engineering: In-house engineering ensures that the EHT systems are tailored to the specific needs of chocolate production, providing precise and efficient temperature control. This ensures accurate and efficient temperature control, which is crucial for various industries, such as the process of trace heating for pipelines, tanks, and vessels.

- Quality Production Facilities: Production facilities and the quality of the EHT products are closely monitored, ensuring that each component meets the highest standards. It is closely monitored to guarantee that the component not only meets but exceeds the highest industry benchmarks.

- Reduced Downtime: The robustness of EHT systems translates to fewer disruptions in production, minimising downtime, and maximising overall operational efficiency. This reliability is instrumental in reducing downtime, ensuring continuous operation, and maximising overall operational efficiency. Eltherms solutions offer unparalleled dependability, translating to a seamless and uninterrupted production process.

In the world of chocolate production, where precision and consistency are paramount, Eltherm’s electrical heat tracing solutions emerge as the golden ticket to success.

However, by entrusting the entire process to a single-source solution, chocolate manufacturers can ensure that their product is not only a feast for the taste buds but also a testament to the reliability and efficiency of modern electrical heating technology.

The Electrical Heating Package

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial | Ramp Heating & Gutter Heating

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV