Fisher Baumann 87000 Valve – Sanitary Control Valves

Fisher Baumann 87000 Valve – Sanitary Control Valves

Fisher Baumann 87000 valve is a sanitary control valve is suitable for use for throttling high purity liquid or gaseous media commonly found in the food and beverage, pharmaceutical, film, and biotechnology industries

87000 sanitary control valve is suitable for repeated steam sterilization cycles with 2.4 bar (35 psi) maximum steam pressures

Assembly of the Fisher Baumann 87000 valve body sections uses only two bolts allowing for ease of cleaning and inspection.

The 87000 valve will drain either horizontally or vertically with the actuator in the horizontal position and in contrast to diaphragm valves, the operation is not affected by vacuum.

Fisher Baumann 87000 Valve – Product Features

- Unique flow pattern allows for self draining in both vertical and horizontal pipelines

- Streamlined low shear flow contours make it ideal for sensitive biomedia

- Flow area between tubing O.D. and body seating is suitable for fine particulant media

- Fool proof bolting method assists with ease of body disassembly and reassembly

- Epoxy powder coated actuator with stainless steel yoke and fasteners for maximum corrosion resistance

- FIELDVUE™ Digital Valve Controller available for remote calibration and diagnostics in facilities utilizing the PlantWeb™ architecture

FISHER BAUMANN 87000 VALVE

PRODUCT Specification

| Sanitary Control Valve Size | NPS 1/2, 18.9 bar CWP (275 psi CWP) |

| Connections | Tri-Clamp or optional welding ends |

| Valve Body Material | 316L SS |

| Valve Body Rating | 275 psig CWP |

| Trim Material | EPDM, VMQ (Silicone), FKM (Fluorocarbon), FFKM (PerFluoroelastomer) |

| Trim Characteristic | Modified Linear |

| Seat Leakage | ANSI/FCI 70-2 Class IV |

| Cv Ratings | 0.25 to 1.25 |

| Bonnet Type | Standard bolted |

| Packing Material | Packless |

| Temperature Range | -18°C to 149°C (0ºF to 300°F) |

Fisher Baumann 87000 Valve – Sanitary Control Valves – Materials of Construction

Fisher Baumann 87000 Valve – Sanitary Control Valves

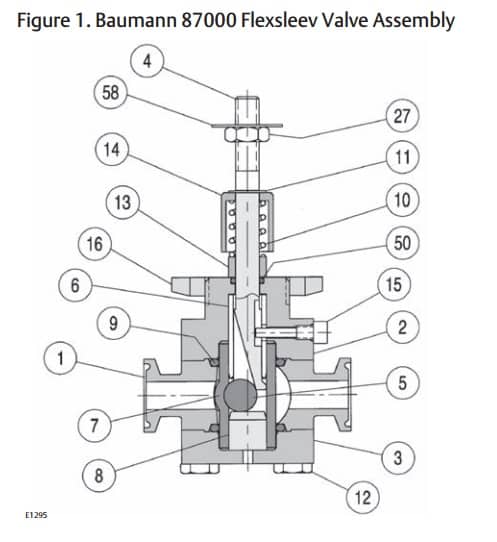

| Key Number | Description | Material |

| 1 | Valve Body | ASTM SA479 (S31600/S31603) |

| 2 | Bonnet, Upper | ASTM SA479 (S31600/S31603) |

| 3 | Bonnet, Lower | ASTM SA479 (S31600/S31603) |

| 4 | Shaft | S21800 SST |

| 5 | Ceramic Ball | Grade 25 Ceramic |

| 6 | Sleeve Bushing | S30300 Stainless Steel |

| 7 | Sleeve | Silicone, fluorocarbon (FKM), EPDM, Perfluoroelastomer (FFKM) |

| 8 | Anvil | S21800 |

| 9 | O-Ring | Silicone, fluorocarbon (FKM), EPDM, Perfluoroelastomer (FFKM) |

| 10 | Spring Stem | Passivated Stainless Steel |

| 11 | Retaining Ring | S15700 |

| 12 | Hex Head Cap Screw | 18-8 Stainless Steel |

| 13 | Spring Seat | 13 Spring Seat PA Nylon 6/6 |

| 14 | Protecting Cap | S30300 Stainless Steel |

| 15 | Alignment Pin | 18-8 Stainless Steel |

| 16 | Drive Nut, (Yoke) | S31600 SST (ASTM A194 Grade 8M) |

| 27 | Jam Nut (locknut) | B8 Stainless Steel |

| 50 | O-Ring | Fluorocarbon (FKM) |

| 58 | Travel Indicator | ASTM A240 S30400 |

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Sanitary Control Valves

Sanitary control valves, with valve bodies manufactured from 316 stainless steel, are specified throughout HVAC, life sciences, pharmaceutical, food and beverage, cosmetics, speciality chemical and R&D industries to provide fluid flow with minimised pressure drop.

The sales of valves to satisfy the stringent sanitation requirements of the pharmaceutical, food and other life science industries in 2015 will exceed $3.4 billion worldwide. This is the last forecast in Industrial Valves World Market published by the McIlvaine Company.

Fisher Rotary Valves: Flow Control For Power, Oil, Gas & Refining Pipelines.

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today, Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson Process Industrial Group.