CEAG Lighting | 10 Reasons to Upgrade to LED for Offshore Hazardous Area Lighting Systems

Published 09 Jun 2019

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

1 Best LightING for Worst Conditons

A driving factor in converting the ATEX lighting on an offshore platform to LED Technology is the constant maintenance requirements of conventional fluorescent type lighting. An offshore rig is subjected to corrosive atmospheres, continuous vibrations, shocks and fire risk. LEDs contain no moving parts, are more durable and withstand shock and corrosion better. The ability of LED type light fittings to ignite spark-free is also an advantage in flammable environments and explosive atmospheres.

2 Increases Lifespan up to 170K Hours

Most industrial LED luminaires and light fittings are rated for 60,000 hours of life at 55ºC. This means that at ambient temperatures of 25°C and 40°C, the useful life of an LED luminaire could be as long as 170,000 hours and 100,000 hours respectively. 170,000 hours equals almost 20 years of continuous, maintenance-free operation for LED type light fittings.

3 Where the Market is headed

LED light fittings currently occupy around 18% of the market, but this is projected to grow in the medium to long term. According to a report from McKinsey, LEDs will represent 60% of the general lighting market by 2020.

4 Less Energy, Less Overhead Costs

Approximately 20% of the power demand on an oil and gas platform each day is consumed by the demands of lighting. This puts managing energy costs at a high priority.

5 Reduce Energy, Save Money

A 50,000 lumen LED floodlight can consume as little as 450W. This is equivalent to a 1500W HID light at a 65% reduction in energy costs.

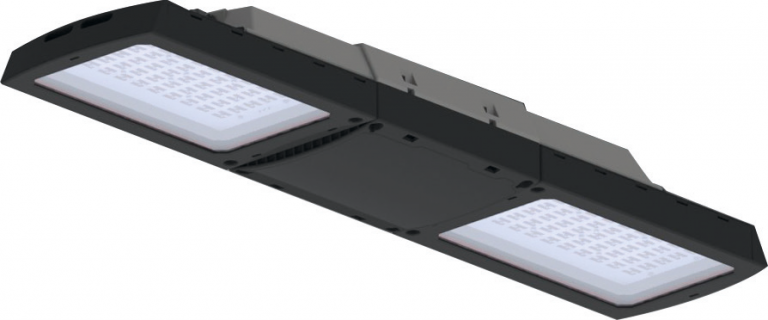

Eaton CEAG | ExLin LED Linear Light Fitting for Zone 1 & Zone 2 Hazardous Areas

6 The Greenest Source of Light

Because of their ability to dramatically reduce energy consumption, LED lights are regarded as a green lighting alternative. And, because they contain no hazardous chemicals, their disposal represents less of an environmental threat.

7 Reduced Maintenance

Most LED products have an L70 rating, which means you can expect them to run 60,000 to 70,000 hours before light output is reduced by 30% of maximum capacity. Some of the most advanced boast ratings of up to 100,000 hours, with performance often improving in cold temperatures. Compared to expected ratings of around 20,000 hours for conventional fluorescent-based fixtures, LEDs offer a potential three-to fivefold reduction in hazardous area repair and maintenance.

8 Toughest of the Tough

The solid-state construction of LEDs light fittings is very robust—meaning they are less prone to premature or unplanned failure in harsh and hazardous locations. This makes them ideal for high vibration and abusive applications.

9 Upgrading to LED Lighting

When Mexico’s largest oil company PEMEX decided to replace existing hazardous area lighting with LED technology, it experienced a 66% reduction in energy consumption.

10 Return on Investment

LED lighting technology has now reached a point where quality is high enough for large-scale industrial application, while LED solutions have become affordable enough to make the financial proposition worthwhile. Current estimates suggest that the general payback period for industrial LED installation is now 3 years or less, down from 10 just a few years ago—and that figure is arguably lower for high power consumption operations such as offshore drilling in the oil and gas sector of the hazardous area industry.

Lighting by CEAG | Hazardous Area Locations & Explosive Atmospheres

CEAG is now EATON | Electrical Equipment for Explosive Atmospheres

CEAG Approved Distributors

Thorne & Derrick are Specialist Distributors of innovative and competitive products to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to your UK and global projects – we have an internationally recognised reputation for the supply of certified equipment to the oil, gas, petrochemical and hazardous area markets.

Hazardous Location certified products and area classifications including UL and C-UL Certification for North America are available including Class I, Division 1 / Zone 1 and Class I, Division 2 / Zone 2 (Flammable Gas & Vapour) and Class II | Zones 21 & 22 (Ignitable Dusts).

See also from CEAG | Switches Control Stations | Emergency Stops Push Buttons | Plugs & Sockets | Terminal & Junction Boxes

Thorne & Derrick are Experts in Equipment for Explosive Atmospheres distributing Explosion Proof products for all required protection concepts including Ex d Flameproof and Ex e Increased Safety.

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control