Class/Division & Zone Ex Markings for Hazardous Locations in North America

Published 19 Oct 2020

Hazcon Inc.

Explosion Protection

& Hazardous Area Equipment

Hazcon Inc. provides a full suite of consulting services for manufacturers of electrical equipment for hazardous locations and explosive atmospheres.

Their primary focus is to help manufacturers prepare for all phases of certification of these products – from product design, approval and installation to certification maintenance.

Electrical equipment must carry the official mark or label of an accredited certifying agency, which indicates that the product has been independently assessed for safety. Equipment nameplates provide a brief summary of the characteristics of the equipment.

For electrical equipment intended to be used in classified areas (known as hazardous locations), the information on markings and nameplates is critical. Such information for equipment used in hazardous locations is intended to enable:

- The end users to procure the correct equipment for a specific application

- The installers (electrical contractors) to install the equipment correctly as per field wiring installation rules for hazardous locations

- The Authority Having Jurisdiction (AHJ) to inspect, approve and enforce the requirements of the Code/Standards related to that piece of equipment

Unclear markings may lead to the incorrect piece of equipment being purchased, installed and inspected for the application and might cause a catastrophic loss. The marking of hazardous location equipment may be complex and confusing, especially in terms of the intended Division or Zone locations, and even more so if multiple methods of protection and both Class/division and Zone markings are used.

“Division” and “Zone” refer to the two distinct classification systems in North America: the Class/division system and the Zone System. The Class/division system is mainly used in North America.

The Zone system of classification originated with the International Electrotechnical Commission (IEC) and is now also commonly used in North America. The intention of both systems is the same – to classify hazardous locations in such a way that the safety of the equipment for use in such locations can be determined.

Manufacturers of electrical equipment seeking North American certification may choose either Class/division marking or Zone marking. However, getting dual markings (both Class/division & Zone markings) is desirable so that the product may be installed in both Division and Zone hazardous areas in North America.

Dual marking helps to makes products more competitive, but keep in mind that there are additional technical requirements and rules and procedures to follow. These rules are outlined in the Standards related to hazardous locations.

Standards Applicable to Hazardous Locations

The requirements related to the installation of hazardous location products are found in Canada in the Canadian Electrical Code (CEC) and in the US in the National Electrical Code (NFPA 70).

Canadian Standards

The installation requirements for Class/division hazardous areas are provided in Appendix J of the Canadian Electrical Code. Section 18 of the Canadian Electrical Code identifies the installation requirements of electrical equipment in Zones hazardous areas.

US Standards

Article 501 of NFPA 70 identifies the installation requirements of hazardous location equipment in Class I, Division 1 and Division 2. Article 505 identifies the installation requirements for Ex Equipment for installation in Zone 0, Zone 1 and Zone 2. The installation requirement of electrical equipment using the Intrinsic safety protection technique is detailed in Article 504 for both Zone and Class/division installation in the USA.

Both the CEC and NFPA 70 permit the installation of Zone-marked products within a Class/Division area in North America and also the installation of Division-marked products in Zones hazardous areas. However, there are some restrictions and limitations for this interchangeable installation between the Division and Zone systems.

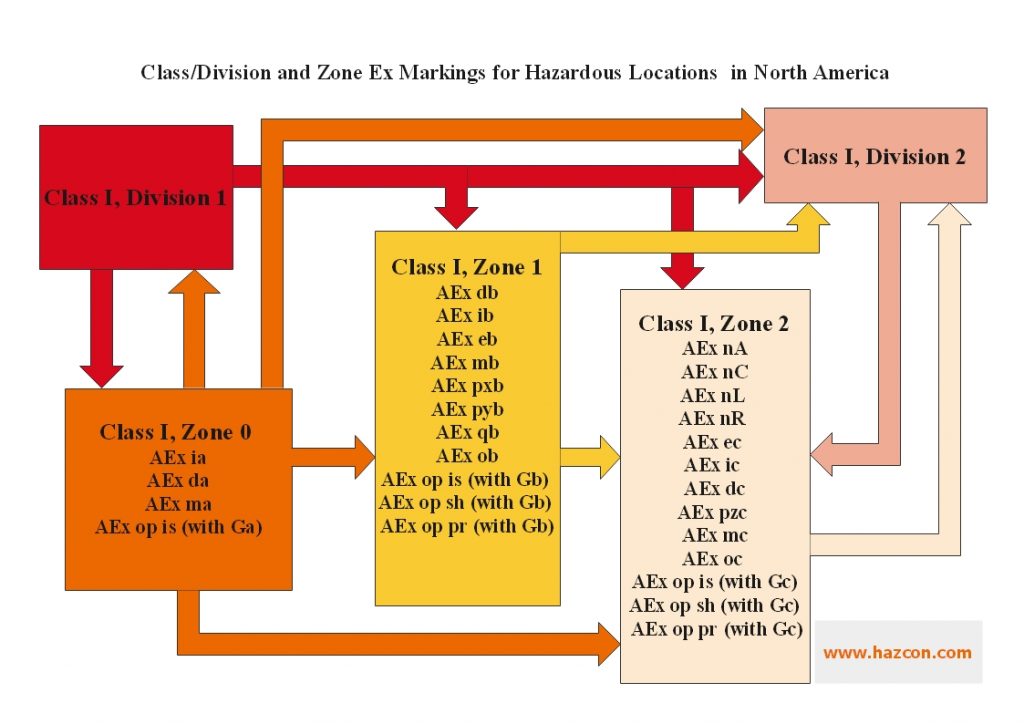

Hazcon Inc. has provided a simplified diagram to show the correlation of Class/division & Zones certified products into Division or Zone areas. This diagram will help installers and manufacturers to have a better understanding of how hazloc products can be installed in hazardous areas in North America.

Further Reading

- Optical Radiation | A Source Of Ignition In Hazardous Areas

- Class I Division 1 Products & Hazardous Area Locations

- Class I Division 2 Products & Hazardous Area Locations

- The Importance Of Grounding Of Intrinsically Safe Devices In Hazardous Areas

- Find Out About Explosion Protection Techniques & Hazardous Area Equipment Protection Levels With Hazcon Apps

Information Courtesy

Behzad Nejad, P. Eng. (Hazcon)

Director & Consulting Engineer at Hazcon Inc.; Hazardous Locations Consulting Services; IECEx, ATEX, CEC & NEC

Specializing in the design, safety and approval of electrical equipment for hazardous locations.

Mr. Nejad has over 15 years of experience as an Electrical Engineer and is a sought after professional in the hzardous area and explosion protection industry. He is fully-qualified at the advanced level of all hazardous locations protection techniques including Intrinsic Safety & Non-incendive, Explosion Proof & Flame proof, Increased Safety, Non-arcing, Purging and Pressurization, Encapsulation, Optical Radiation, and Dust-tight enclosures. Mr. Nejad’s tenure in the industry includes six years at the CSA certification agency, working closely with manufacturers (Emerson, GE, ABB, Siemens, Endress-Houser, VEGA etc.) as a technical and certification engineer for Hazardous locations equipment.

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery