Electrical Resistance Trace Heating According to DIN EN 60079-30-1

Published 08 Dec 2020

Trace Heating

DIN EN 60079-30-1

Electrical resistance trace heaters are used for heating fittings, conduits and tanks. Resistance trace heating are understood as meaning, according to the standard DIN EN 60079-30-1, the use of electrical trace heaters, trace heater pads or trace heater panels and auxiliary components applied from outside, in order to increase or maintain the temperature of the contents of pipe networks, tanks and associated equipment.

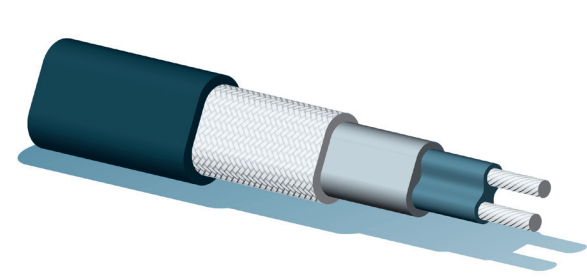

A trace heating cable produces and transmits heat based on Ohm’s law. The field of application ranges from frost protection to the prevention of condensation in gas analysis and to the heating of media for production and processing.

Ohm’s Law states that electric current is proportional to voltage and inversely proportional to resistance.

This is where electrical resistance heaters are more suitable than the previously frequently used vapour- operated trace heaters as they work extremely economically and more accurately in terms of temperature. Electrical resistance trace heating manufactured by Eltherm and distributed by Thorne & Derrick are often the basis for a optimum process sequence and have become indispensable in many areas and applications in todays industry.

Self-Limiting Heating Cable

Outcome of using Electrical Resistance Heating

When electrical resistance heaters are used in hazardous area apart from the technical component, the basic requirements and safety specifications of the corresponding Ex standards must also be observed.

However not every resistance heater is suitable or admissible for use in hazardous areas, but each one must always be carefully selected and considered from two sides during planning and construction. On the other hand a basic feature of the product is suitability application in the process compared to the inclusion of type specific properties on the heater- when operated in accordance with its intended use and during malfunction.

If the application requires a higher heating power, making a stabilised application no longer possible, due to the resulting higher operating temperature and without an additional temperature limiting device. The critical limiting temperature will be exceeded in normal operation as well as in case of error or becoming a source of danger in the hazardous area.

These requirements and safety relevant protective measures must be taken into account when planning to use ATEX trace heating for operation according to its intended use in hazardous areas.

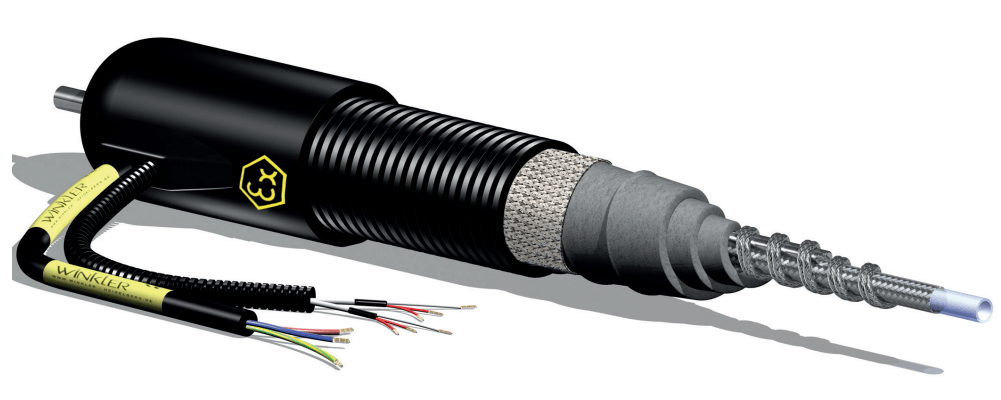

System-certified analyser heated hose

Temperature Monitoring of the Resistance Heating

The trace heating system is designed so the sheath temperature of the trace heater meets with the standard conditions and is limited to the temperature classification (T1-T6) or ignition temperature.

This should also require certain safety margins from the maximum operating temperature, which is minus 5K at the temperatures below or equal to 200°C and minus 10Kelvin at temperatures above 200°C.

These requirements can be satisfied either by means of a stabilised design or by using a temperature monitoring system at the resistance heater.

|

Resistance Trace Heating Hose |

Key Benefits of using resistance heating systems:

- Helps to maintain temperatures of the contents of pipe networks using the heating systems

- Helps to combat against frost and condensation of gas

- Work extremely economically and accurately in terms of temperature

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locking & Access Control