KROHNE Flow Meters | Internal Monitoring Of Natural Gas Quantities

Published 11 Jun 2020

Process Measurement Instruments – Flow, Temperature, Level & Pressure Measurement

KROHNE Flow Meters

Process Instrumentation for Industrial, Hazardous Area & Explosive Atmopheres

Ultrasonic Flow Measurement

KROHNE flowmeters and measurement instruments provide accurate and reliable measurement of industrial liquids, gases and other media (including emulsions, corrosive liquids and gases) with a range of low/high flow rates.

KROHNE is a world-leading manufacturer and supplier of solutions in industrial and explosive atmosphere process instrumentation – with over 30 worldwide approvals for hazardous area gas and dust Zones including ATEX, IECEx, usFMc, NEPSI, INMETRO, KGS, GOST-R and PESO/CCOE. The range of flowmeters manufactured by KROHNE incorporates multiple explosion proof and protection concepts – including IS (Intrinsically Safe) and Ex d (Flameproof) for flow measurement and metering in the hazardous area industries.

Flowmeters by KROHNE | the world-leading manufacturer and supplier of solutions in industrial and hazardous area process instrumentation: flow meters, level meters, temperature meters and pressure measurement.

Background

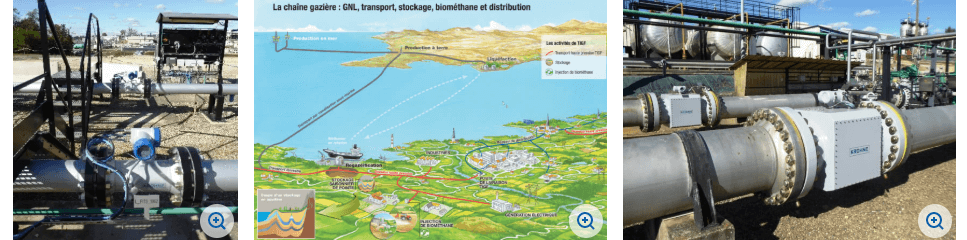

TIGF, headquartered in Pau, France, is one of the main operators of the French natural gas transport network and specialises in natural gas storage. After it is extracted, the gas is processed and then transported either via gas pipeline or in liquefied form.

When transporting in liquid form, the gas is loaded into liquefied natural gas tankers and taken to the designated receiving terminal. The gas is then processed, stored and gasified once again before being fed into the network and delivered to end consumers.

Flow Measurement requirements

The customer must measure the stored, compressed and transported natural gas. Measuring the transported product volume requires a great deal of accuracy.

Depending on the measuring point, the natural gas temperature may vary between 10…50 °C / 50…122 °F, the pressure may be between 30…85 bar / 435…1232.5 psi and the flow rate between 0…30 m/s / 0…98.5 ft/s.

A measurement of the gross volume flow is the starting point and the pressure and temperature compensation (in other words the conversion to standard volume) takes place automatically.

Measuring accuracy is extremely important for TIGF as they need to be able to control the internal process from the storage facilities to the transport arteries at any time.

The gas goes through various processing steps in the process. The company was thus looking to improve its internal gas measurements.

The customer had previously used orifice plates or outdated ultrasonic flowmeters and was looking for a more reliable measuring solution from KROHNE.

The customer specified the need for flowmeters with ATEX approval (Ex d), ASME flanges (Cl 600) and sealing rings. The instrumentation needed to be temperature resistant to -29 °C / -20.2 °F (the steel needed increased resistance in case of sudden decompression). It was also necessary for the flowmeter to be unsusceptible to any moisture occurring in the gas.

KROHNE Solution

A total of 14 OPTISONIC 7300 ultrasonic flowmeters and 3 ALTOSONIC V12 ultrasonic gas flowmeters were installed.

The nominal sizes of the flowmeters ranged from 8…24″, with ASME RTJ flanges (Cl 600) and sealing rings, and were installed into mainly horizontal pipelines. However, two of the installations were in fall pipes with the appropriate inlet runs (10 D/5 D).

KROHNE Flowmeters

Customer benefits

IGF standardised its equipment fleet park with reliable and accurate instrumentation. The customer benefits from a reliable overview of the gas flow and now has better control over its facilities as a result of the improved management of the internal gas metering.

- Flow measurement of natural gas at a storage facility

- Increased requirements for measuring accuracy

- Improved management of internal gas measurements

Explosive Atmosphere Experts

Thorne & Derrick are Specialist Distributors of Hazardous Area Electrical, HVAC & Process Instrumentation Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

We supply major UK and international infrastructure projects and also MRO (Maintenance, Repair, Operations) requirements for both planned and unplanned plant shutdowns – we react with a rapid response to customer demand to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

We distribute Innovative products to manage the planned replacement of legacy equipment conformant with international classifications including ATEX and IECEx.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

➡ Also Process Instrumentation Products: Ashcroft Pressure Gauges | ASCO Valves | Katronic Flow Meters | KROHNE Flow Meters | VEGA Level Sensors | Rotronic Temperature & Humidity Sensors

Further Reading

-

KROHNE Flow Meters – Ultrasonic Flow Measuremet For Internal Monitoring Of Natural Gas Quantities – Application Report

Size: 718.44 KB

KROHNE Flow Meters – Ultrasonic Flow Measuremet For Internal Monitoring Of Natural Gas Quantities – Application Report

Size: 718.44 KB