NACE Standards | Measuring Pressure of Sour Gas & Crude Using Ashcroft Gauges

Published 16 Jun 2020

NACE Standards Whitepaper

Measuring the Pressure of Sour Gas and Crude

Every mechanically activated pressure instrument relies on an elastic element to bend in response to a pressurized medium.

Most often, the element is a metallic “C” shaped or coiled Bourdon tube that attempts to straighten under pressure. Specifiers need to be especially careful that the chemical composition of the excitation medium does not react unfavorably with the instrument’s wetted materials. Measuring the pressure of compressed air or water seldom results in an incompatibility.

However, when oil and gas first come out of the ground, the story can be quite different.

Both hydrogen sulfide (H2 S) and carbon dioxide (CO2, when combined with water forms carbonic acid) can exist as unwanted components.

Raw petroleum fluids infused with hydrogen sulfide are known as “sour gas” or “sour crude”, and can attack containment materials, causing stress corrosion cracking. This can lead to a breach in the vessel and allow gas or oil to escape into the surrounding environment.

The consequences can be disastrous.

To measure harsh pressure media, it is preferable to use an instrument or gauge with compatible wetted parts. However, this choice is limited by the ability of compatible materials to perform adequately as a Bourdon tube. The alternative is to isolate the pressure instrument from corrosive media by installing a diaphragm seal in between.

Although offered in a variety of corrosion-resistant materials, not all will be impervious to every combination of application variables. Given the consequences of component failures, the selection of appropriate materials and best practices is paramount.

So what are the correct materials? Who will make the determination?

How It Started

Founded in 1943 by corrosion engineers working in the pipeline industry, the National Association of Corrosion Engineers set out “To protect people, assets, and the environment from corrosion”.

By the 1960s, they had begun to develop control standards that would establish appropriate materials for a wide variety of corrosive applications, including oil and gas production and refinery facilities.

In 1993, the organization was renamed “NACE® International” after having grown in scope, importance and geography.

Gauges & Pressure Switches | IECEx & ATEX Certified for Explosive Atmospheres Explosion Proof | UL CSA CE CRN SIL 3 Capable FM ATEX IECEx | View Pressure Gauges

WHAT DOES NACE SPECIFY?

NACE offers over 150 standards that address metal corrosion in a vast number of applications ranging from exposed metal structures to corrosion resistant coatings on railroad cars.

For purposes of this overview, the discussion will be limited to the NACE standards that specifically address corrosion resulting from exposure to sour gas or sour crude.

Two primary NACE standards are MR0103 that applies to refineries, and MR0175 (also adopted by ISO as 15156) which is directed to oil and gas production. Both apply to metals only, and do not address plastics or elastomers.

Using materials selected in accordance with these NACE standards will reduce the likelihood of failure due to stress corrosion cracking in sour environments.

MR0175 / ISO 15156 – 2009: “Materials for Use in H2S Containing Environments in Oil and Gas Production”. This specification has been adopted as a worldwide standard by NACE, ANSI, and ISO. It is divided into three sections, separately addressing general requirements, ferrous alloys, and corrosion resistant alloys as used

in sour oil and gas field applications.

MR0103 – 2010: “Materials Resistant to Sulfide Corrosion Cracking in Corrosive Petroleum Refining Environments”. This document addresses the selection of materials in oil and gas refineries. Refinery environments are typically less severe than production environments, due to lower chloride concentrations and higher pH levels. As a result, MR0103 tends to be less stringent than MR0175 / ISO15156.

These NACE specifications only consider stress corrosion cracking due to exposure to H2S and other corrosives and do not address general or localized corrosion.

Additionally, the standards restrict the usage of many alloys by limiting the temperature, pH, and/or composition to which these alloys may be exposed.

It is the responsibility of the specifier to select an appropriate instrument or component with the correct features for their particular set of variables to ensure NACE compliance.

The Variables

Temperature

The temperature of the process medium can have a significant effect on the ability of any material to resist corrosion. Stainless steels are especially sensitive to temperature, especially when chlorides are present.

Chemistry

The presence of hydrogen sulfide, chlorides (salts, often from subterranean salt deposits) and carbon dioxide can all contribute to corrosion. The quantities and combinations of these compounds will also be a factor in determining the adequacy of specific metals.

pH

Whether the pressure media are acid or base is another consideration. Low pH (acids) can increase corrosion rates and cause hydrogen liberation that can result in embrittlement of the metal.

Metallurgical Condition

Hardened metals are more susceptible to stress fractures. Annealed metals are softer and less likely to crack, but have a lower tensile strength.

ASSURING THAT A COMPONENT IS COMPLIANT

To ensure that a component meets the NACE standards, determinations can be based on:

Meeting the Conditions Specified in the Standard

By following the NACE recommendations, all requirements will be met. When in doubt, use materials that are compliant with the worse-case application.

Laboratory Testing

Laboratory tests that recreate applicable test variables defined in the standard will ensure that the tested materials and components will be compatible. Certified testing labs with experience in this type of testing will establish and execute an appropriate test protocol.

Field Experience

Components that have been in service and have not succumbed to corrosion over an appropriate period of time may be documented and considered a proof test for the specific application.

SO WHAT MATERIALS CAN BE USED?

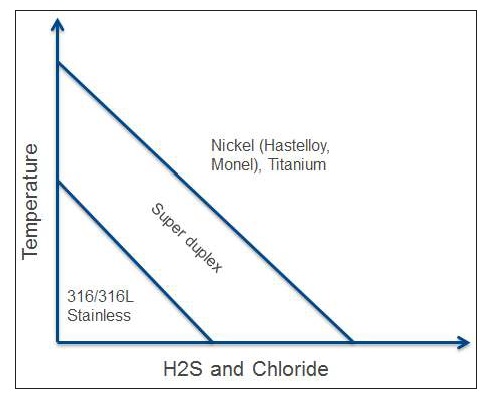

Depending upon the severity of the corrosive conditions, different materials may be safely employed. In these cases, metal choices are a function of cost. While Hastelloy® C22/C276 or titanium may be the best choice to ensure unquestionable compatibility, the price for these specialized metals would add unnecessary cost to facilities handling less harsh media.

The list and chart below provide a simplified reference for choices of metals tested and used by Ashcroft as elastic elements and other wetted parts, (in compliance with NACE MR0175):

Favorable Conditions

(Low concentrations of hydrogen sulfide and chlorides)

- Stainless Steels (316 is most commonly used)

- Alloy 20

Moderate Conditions

(Where higher temperatures can begin to hasten corrosion, depending on the chemistry of the media)

- Super Duplex Steels

- Alloy 400 (Monel®)

Extreme Conditions

(High concentrations of hydrogen sulfide, chlorides and acids and high temperatures pose a risk of stress cracking due to corrosion. Titanium and Nickel, Chromium and Molybdenum alloys are best, but most expensive)

- Hastelloy® C22/C276

- Alloy 400 (Monel®)

- Titanium

NACE specifications are detailed and can be complex when addressing combinations of variables. Regardless, they are important and necessary requirements for the safe measurement and control of raw, corrosive gas and oil that have been extracted from the ground or seabed.

To learn more about NACE specifications, visit www.nace.org.

This article was written by John Carissimi (Media Manager) and Jeremy Payne (Materials and Testing, Engineering Manager) of Ashcroft Inc. With over 160 years of experience, Ashcroft manufactures pressure and temperature instrumentation, including media isolation devices, for a wide variety of industries throughout the world, including oil and gas processes.

These pages have not been reviewed/approved by NACE® International and are offered as an introductory reference only. Specifiers and users should refer to the published NACE specifications to establish the correct materials for their applications.

Explosive Atmosphere Experts

Thorne & Derrick are Specialist Distributors of Hazardous Area Electrical, HVAC & Process Instrumentation Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

We supply major UK and international infrastructure projects and also MRO (Maintenance, Repair, Operations) requirements for both planned and unplanned plant shutdowns – we react with a rapid response to customer demand to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

We distribute Innovative products to manage the planned replacement of legacy equipment conformant with international classifications including ATEX and IECEx.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

➡ Also Process Instrumentation Products: Ashcroft Pressure Gauges | ASCO Valves | Katronic Flow Meters | KROHNE Flow Meters | VEGA Level Sensors | Rotronic Temperature & Humidity Sensors