New USB Intrinsic Safety Barrier Installed In A Purged & Pressurized Enclosure For Stand-Alone Applications

Published 21 Oct 2019

USB Intrinsic Safety Barrier

SK-PC-Z1D1-UU1-10-HS

Pepperl+Fuchs are pleased to announce an addition to their HMI device accessories range: the new USB intrinsic safety barrier SK-PC-Z1D1-UU1-10-HS.

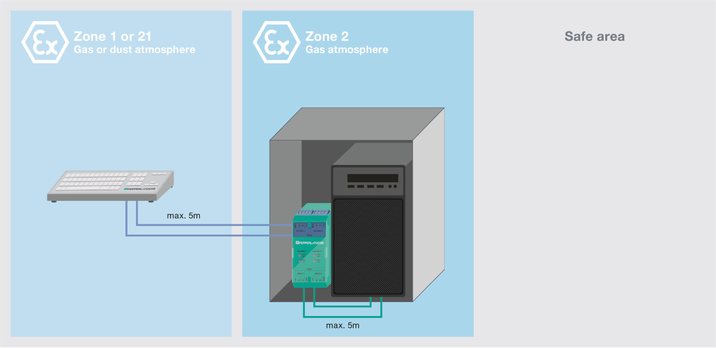

The new barrier connects a host device, such as an industrial PC, to a USB device, such as a Pepperl+Fuchs EXTA2/EXTA3 keyboard or a flash drive, in a Zone 1/21 environment.

The barrier is able to change the two USB channels into intrinsically safe circuits enabling transmission of USB signals from and into hazardous areas.

USB Intrinsic Safety Barrier – SK-PC-Z1D1-UU1-10-HS

SK-PC-Z1D1-UU1-10-HS

Features

- For installation in Zone 2 environments, supplies keyboards in Zone 1/21

- 2 USB channels

- Data rates up to 480 Mbit/s

- Max. cable length 10 m (5 m before device, 5 m after device)

- Powered via USB, no separate power connection required

- Powered via USB host—no extra power supply needed

- Flexible installation in non-hazardous areas

- Various options allow installation in explosion-hazardous locations

- Rugged design

- Tested and qualified for use with Pepperl+Fuchs EXTA2 keyboards and qualified flash drives

Rugged Design and Flexible Installation

SK-PC-Z1D1-UU1-10-HS USB intrinsic safety barrier is shock and vibration resistant thanks to its rugged design.

Two 4-screw terminal blocks ensure a robust connection. Flexible installation is a major advantage and can be adapted to suit the needs of the customer and application. With its wide operating temperature range of -20 °C up to +60 °C, the USB barrier is also suitable for use in extreme temperatures.

A suitable enclosure that corresponds to at least IP54 in accordance with IEC/EN 60079-0 allows the barrier to be used in Zone 2/22, while the connected EXTA2 keyboard can be installed in Zone 2/22 or 1/21.

The USB intrinsic safety barrier is installed in the non-hazardous area, while connected devices are in explosion-hazardous areas.

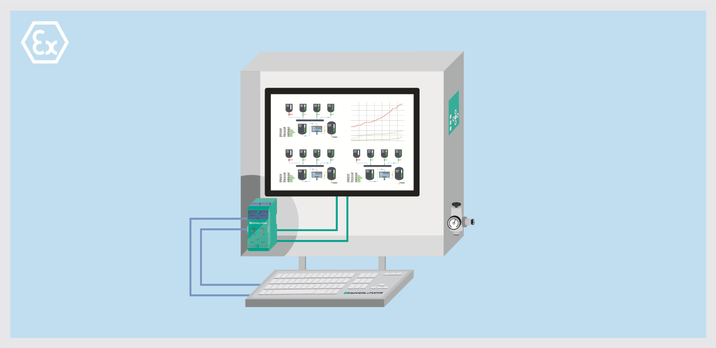

Another option for use in explosion-hazardous areas is installing the USB barrier in a purged and pressurized enclosure. Since the USB barrier provides an intrinsically safe circuit, the connected USB keyboard does not need to be purged and pressurized if it is certified for use in Zone 1/21.

A suitable enclosure allows the USB barrier to be installed in Zone 2

The USB barrier installed in a purged and pressurized enclosure.

USB Intrinsic Safety Barrier

Specification

| Supply | |

|---|---|

| Input voltage | 4.75 … 5.1 V DC (Um = 60 V SELV/PELV) |

| Input current | max. 200 mA |

| Power consumption | max. 2.7 W |

| Interface | |

| Interface type | 4-screw terminal MSTBT 2.5 HC / 4-STP GY7035 USB 2.0 compatible |

| Directive conformity | |

| Electromagnetic compatibility | |

| Directive 2014/30/EU | EN 61326-1:2013 (industrial locations) , EN 61000-6-4:2007+A1:2011 |

| RoHS | |

| Directive 2011/65/EU (RoHS) | EN 50581:2012-09 |

| Ambient conditions | |

| Operating temperature | -20 … 60 °C (-4 … 140 °F) -20 °C ≤ Ta ≤ 60 °C / 70 °C (depending on installation conditions) |

| Storage temperature | -40 … 85 °C (-40 … 185 °F) |

| Relative humidity | < 95 % non-condensing |

| Shock resistance | 18 shocks 15 g , 11 ms all axis, IEC 60068-2-27 |

| Vibration resistance | 10 … 150 Hz , ± 0.075 mm, 1 g, 10 cycles per axis according to EN 60068-2-6 |

| Mechanical specifications | |

| Degree of protection | IP20 |

| Material | ME MAX 45 2-2 KMGY-2713706 refer to 42-3388 |

| Cable | shielded cables must be used |

| Mass | approx. 220 g |

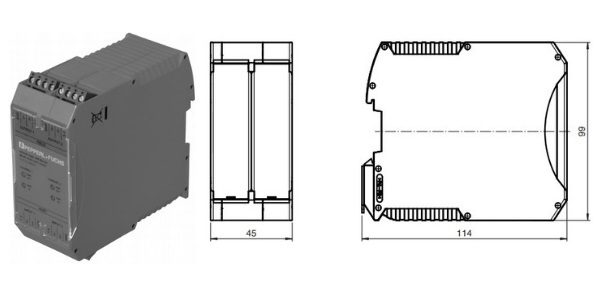

| Dimensions | 45 mm x 99 mm x 114 mm |

| Mounting | DIN rail mounting |

| Cable length | 5 m before device , 5 m after device , 10 m total |

| Data for application in connection with hazardous areas | |

| EU-Type Examination Certificate | EXA 18 ATEX 0054X |

| Marking | Ex II 3(2) G Ex ec [ib Gb] IIC T4 Gc Ex II (2) D [Ex ib Db] IIIC |

| Directive conformity | |

| Directive 2014/34/EU | EN 60079-0:2012+A11:2013 , EN 60079-7:2015 , EN 60079-11:2012 |

| International approvals | |

| IECEx approval | IECEx EXA 18.0008X |

| Approved for | Ex ec [ib Gb] IIC T4 Gc [Ex ib Db] IIIC |

| Standards | IEC 60079-0:2017 , IEC 60079-7:2015 , IEC 60079-11:2011 |

New USB Intrinsic Safety Barrier – Dimensions

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Further Reading

-

USB Intrinsic Safety Barrier – Data Sheet

Size: 442.01 KB

USB Intrinsic Safety Barrier – Data Sheet

Size: 442.01 KB